Differential ratchet type anti-loosening double nut

A double nut and ratchet technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of difficult processing, complex structure, unable to prevent the relative rotation of double nuts, etc., and achieve the effect of improving the anti-loosening effect and simple installation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

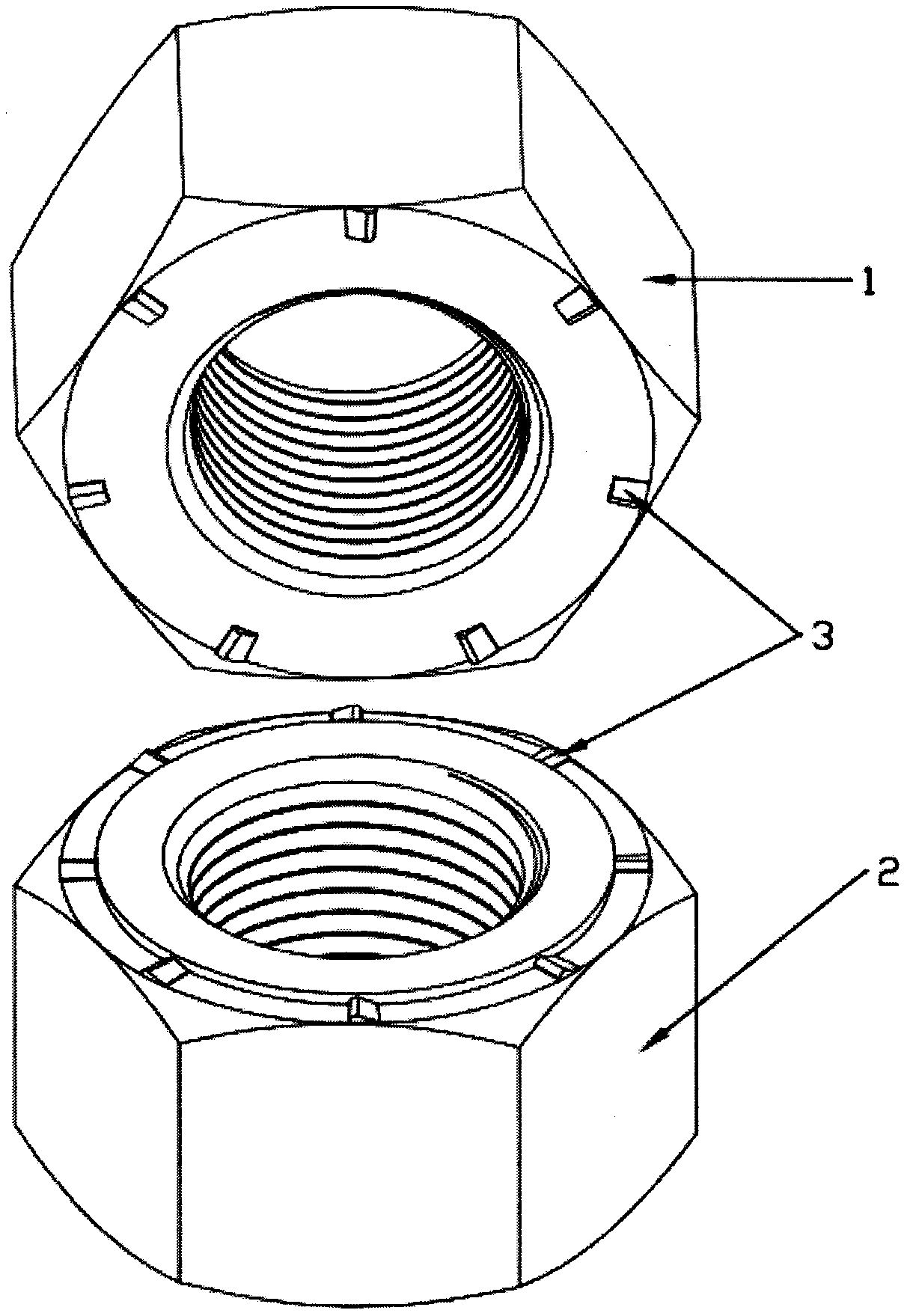

[0014] Such as figure 1 As shown, taking the M30 nut as an example, the upper nut has 7 ratchets, the lower nut has 8 ratchets, the ratchets are set on the end surface of the nut, the ratchets of the upper nut are set Located on the upper end face, each ratchet occupies less than one fifty-sixth of a circle in the circumferential direction, the tooth height is about 1mm, the tooth width is about 3mm, and the top of the tooth has rounded corners. The ratchet direction of the upper and lower nuts is easy Tighten, difficult to unscrew. When installing, tighten the lower nut first, and then screw the upper nut. When the end faces of the upper nut and the lower nut come into contact, a group of ratchets will start to bear force and cause resistance to tightening the upper nut. Further increase the tightening torque. Due to the elastic deformation of the nut and the bolt With the existence of the ratchet, this group of ratchets will cross and mesh with each other, and every 1 / 56th ...

Embodiment 2

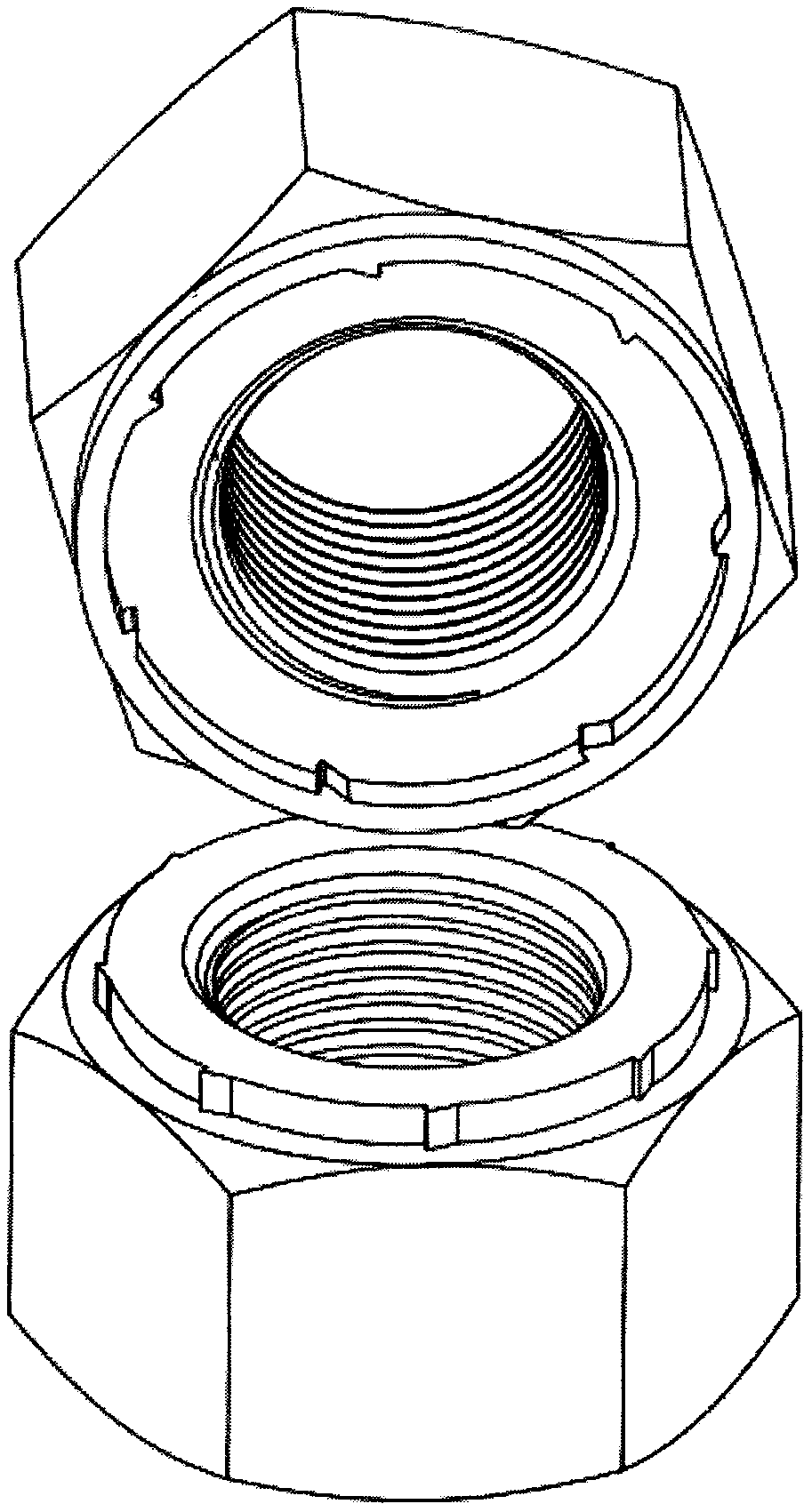

[0016] Such as figure 2 Shown, the ratchet of upper and lower nuts is located on the circumferential surface of the nut, and all the other are the same as embodiment 1. In this embodiment, the ratchet teeth are arranged on the circumferential surface of the nut, and the ratchet teeth are not affected by the huge extrusion force between the two nuts. During installation, the radial elastic deformation of the nuts is used to realize the ratchet teeth crossing and meshing with each other, which overcomes the problem of implementation. The disadvantage of the ratchet in Example 1 is that it is easily crushed and damaged during installation. The disadvantage is that the manufacturing difficulty is greater than that of Example 1.

Embodiment 3

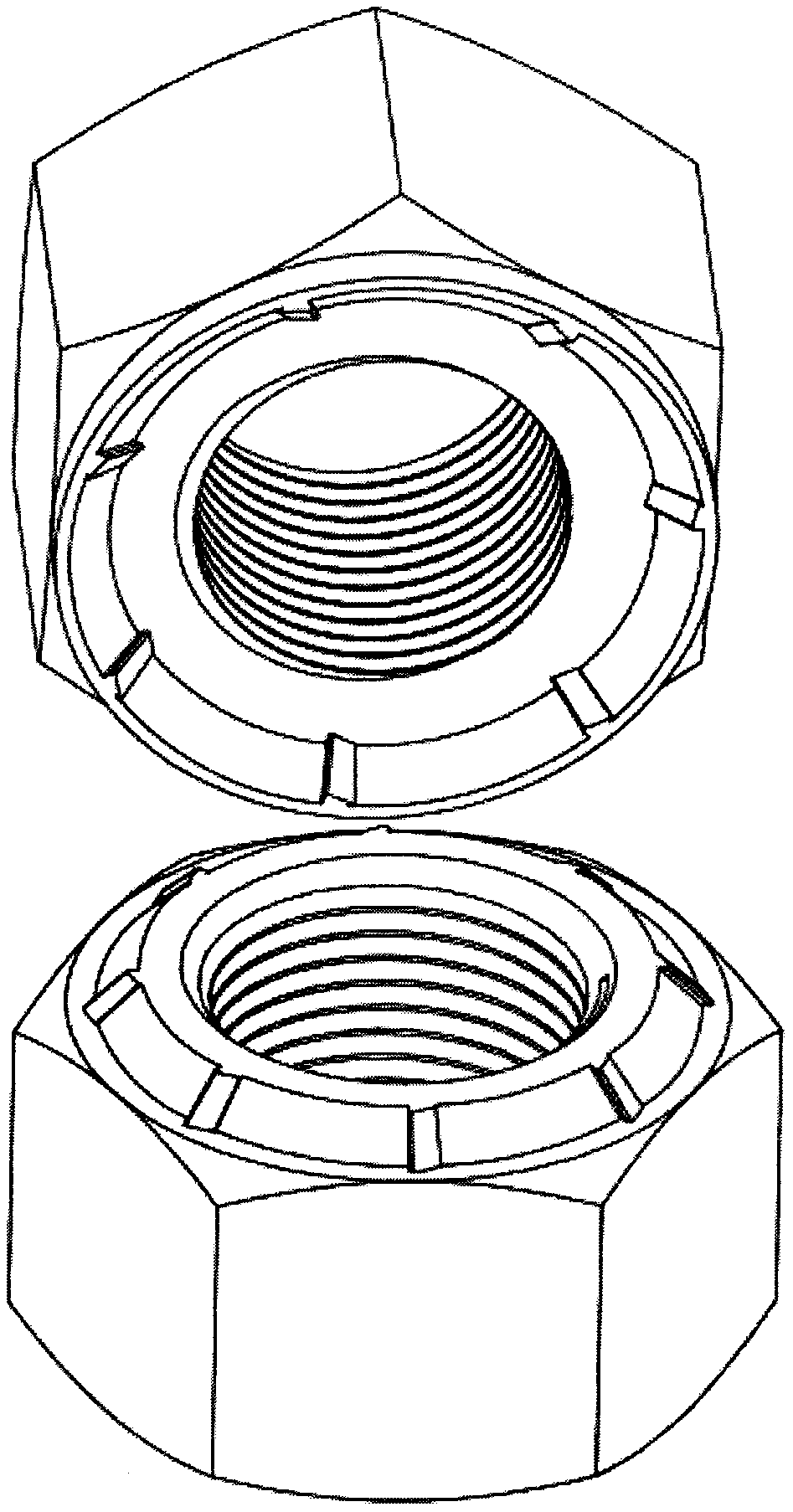

[0018] Such as image 3 As shown, the ratchets of the upper and lower nuts are located on the conical surface of the nut, and all the other are the same as in embodiment 1. In this embodiment, the ratchet teeth are arranged on the conical surface of the nut, and the nut can be elastically deformed in both the radial direction and the axial direction during installation to realize the ratchet teeth crossing and meshing with each other, taking into account the advantages and disadvantages of the first and second embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com