Thin-walled profile punching machine

A technology for punching machines and profiles, applied in the direction of punching machines, presses, manufacturing tools, etc., can solve the problems of restricting the development and application of punching machines, high price, slow punching speed of hydraulic punching machines, etc., and achieve low manufacturing cost , High work efficiency, fast punching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

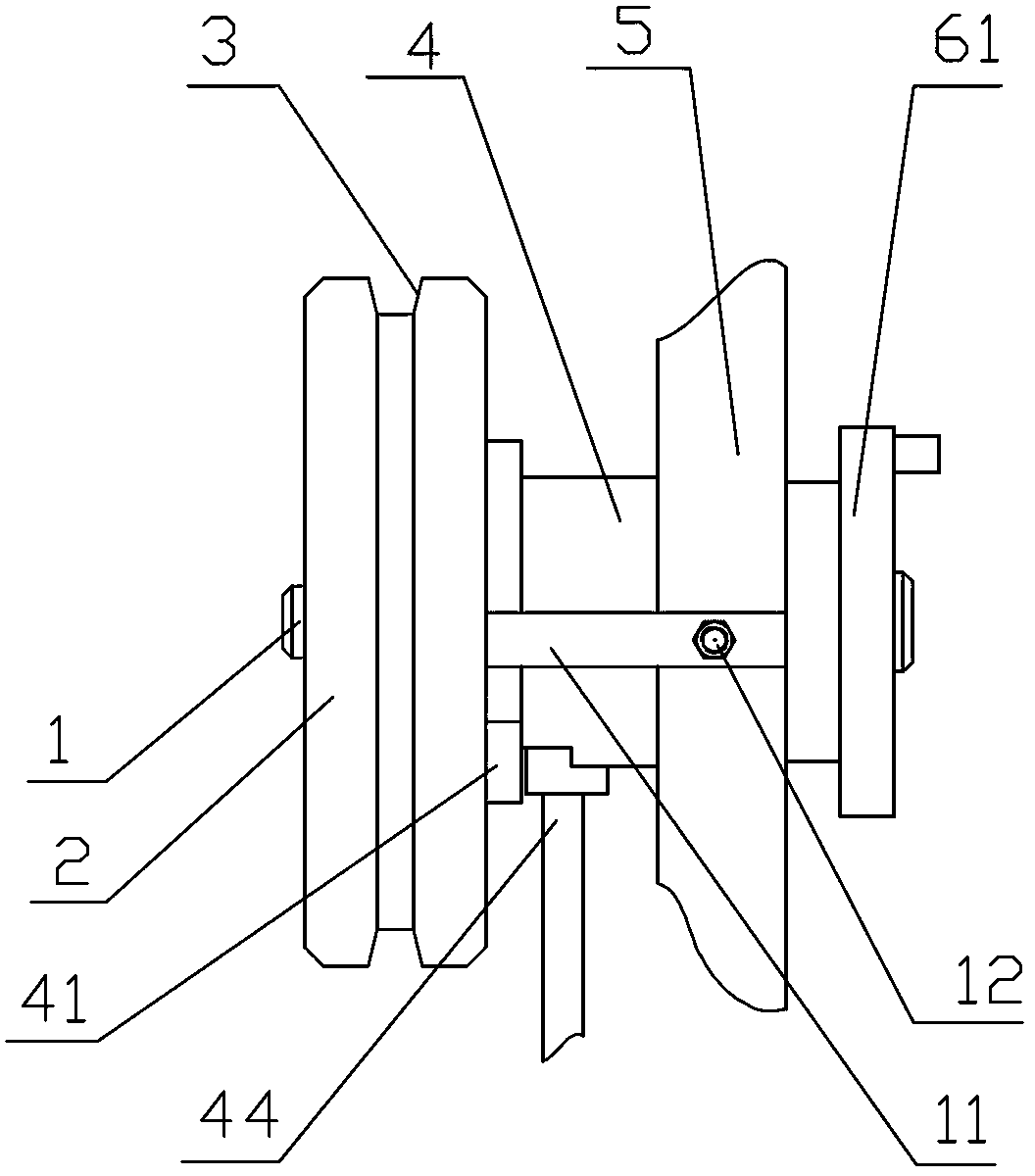

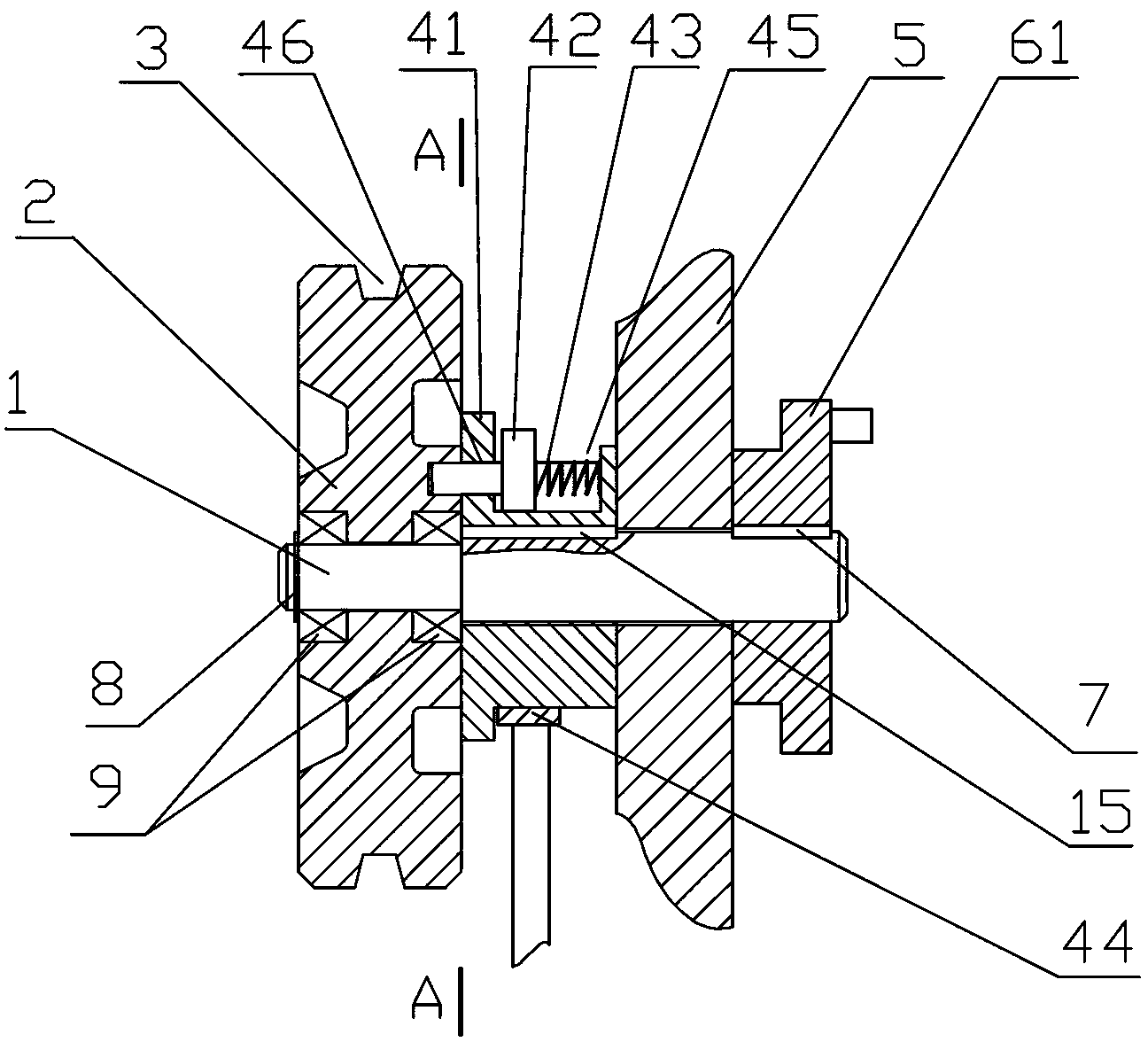

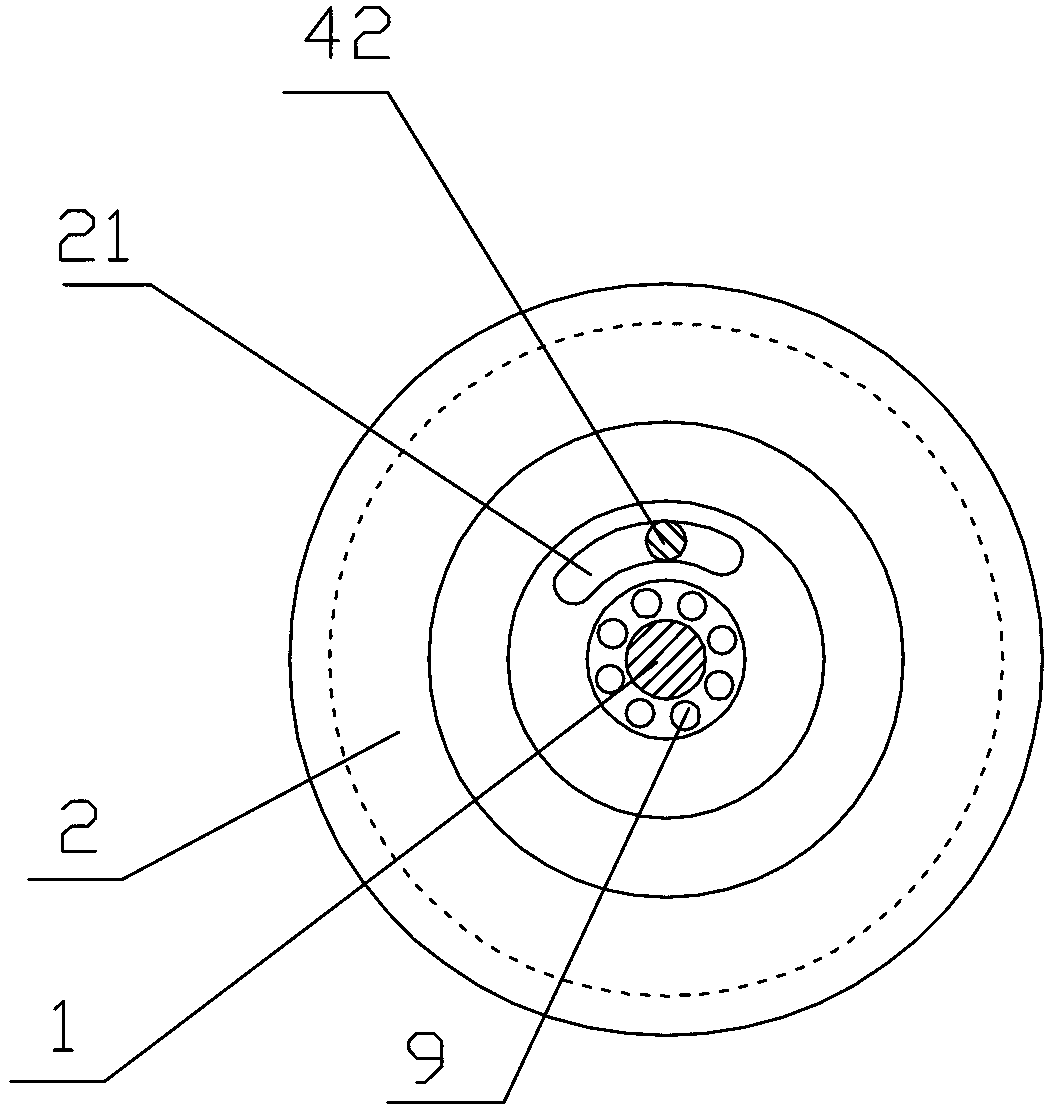

[0021] Such as Figure 1 to Figure 6 As shown, the thin-walled profile punching machine of the present invention includes a fuselage body 5, a motor (not shown in the figure), a transmission mechanism, a punching device 6, a main shaft 1 and a rotating energy storage component 2 sleeved on the main shaft 1 . The power generated by the motor is transmitted to the rotating energy storage component 2 through the transmission mechanism. The driving disk 61 of the punching device 6 is connected to the main shaft 1 through the key I7.

[0022] The thin-walled profile punching machine also includes a clutch brake device 4 installed on the main shaft 1, and the clutch brake device 4 includes a disc bushing 41, a clutch brake pin 42, an elastic member 43 and a clutch brake device. The rod 44 and the disk bushing 41 are connected to the main shaft 1 through the key II15 and are adjacent to one side of the rotating energy storage component 2. The side of the disk bushing 41 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com