Egg collector clutch device

A technology of clutch device and egg collector, which is applied in the direction of mechanically driven clutches, clutches, and clutches that mesh with each other, can solve the problems of difficulty in ensuring the holes on the slender shaft and the sprocket, complex structure, etc., and achieve simple structure and high precision. Undemanding, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

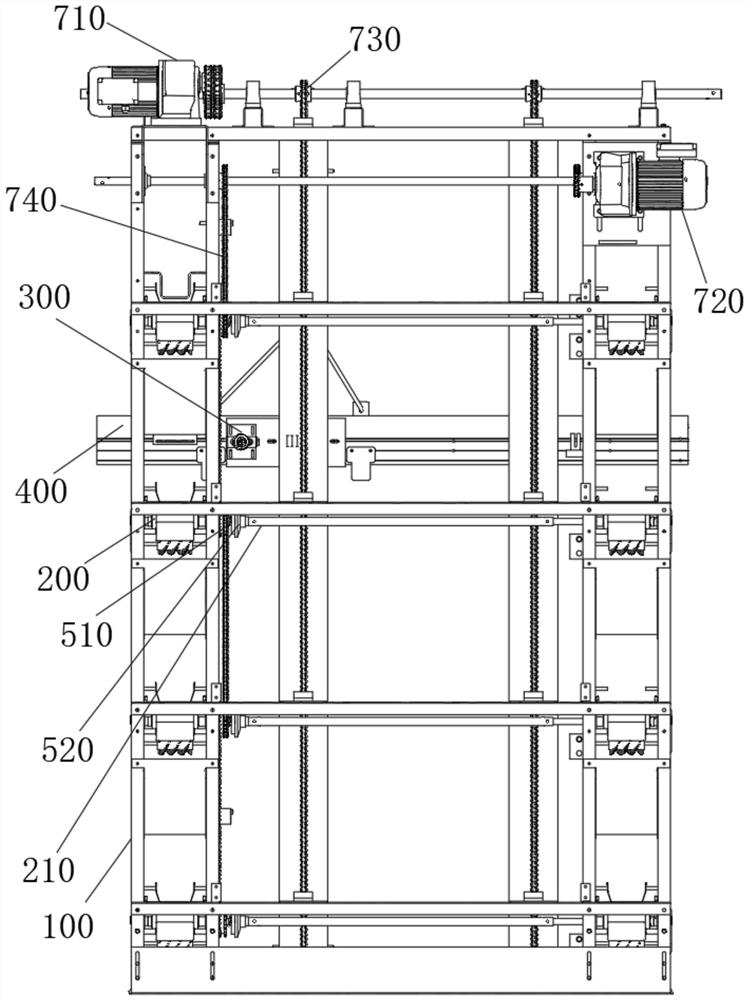

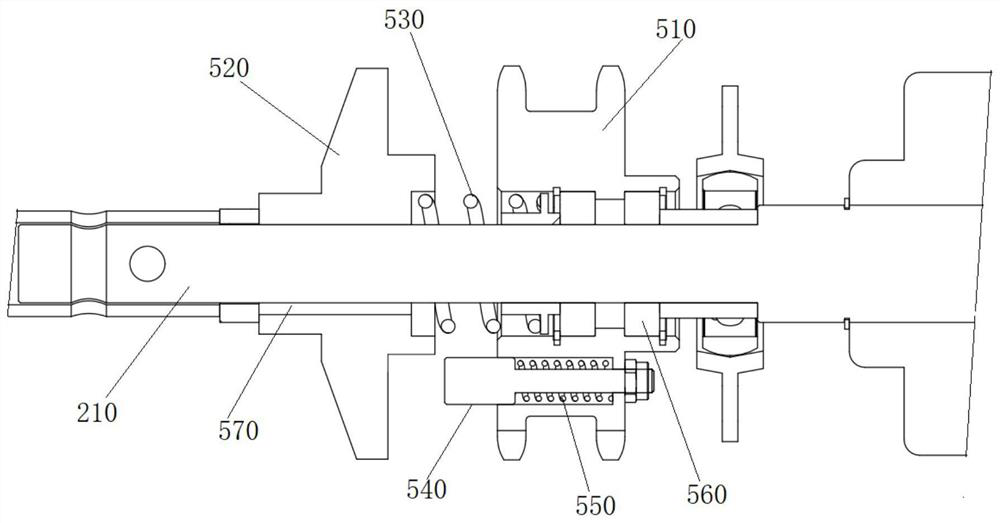

[0027] An egg collector, such as figure 1 As shown, it includes a frame 100. Egg belts are arranged at vertical intervals at both ends of the frame 100. The corresponding egg belts are provided with an egg belt driving mechanism 200. A central egg line 400 is provided in the center of one side of the frame 100. The clutch The active mechanism is located on the central egg line 400, and the corresponding central egg line 400 on the frame 100 is provided with a lifting mechanism for realizing the central egg line 400 to move up and down.

[0028] Specifically, the lifting mechanism includes a sprocket transmission system for realizing the vertical movement of the central egg line 400 corresponding to the central egg line 400 and a guide rail for guiding the vertical movement of the central egg line 400. The corresponding guide rails are set on the central egg line 400. There is a slide block, and the central egg line 400 moves vertically along the frame 100 through the cooperati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com