A kind of sandwich type rare earth polyacid and layered rare earth hydroxide intercalation composite material and its preparation method and application

A technology of rare earth hydroxides and rare earth polyacids, which is applied in the fields of refining oxygen-containing compounds, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., can solve the problems of difficult separation and recovery of catalysts, and achieve Strong industrial application prospects, high catalytic activity and selectivity, and effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

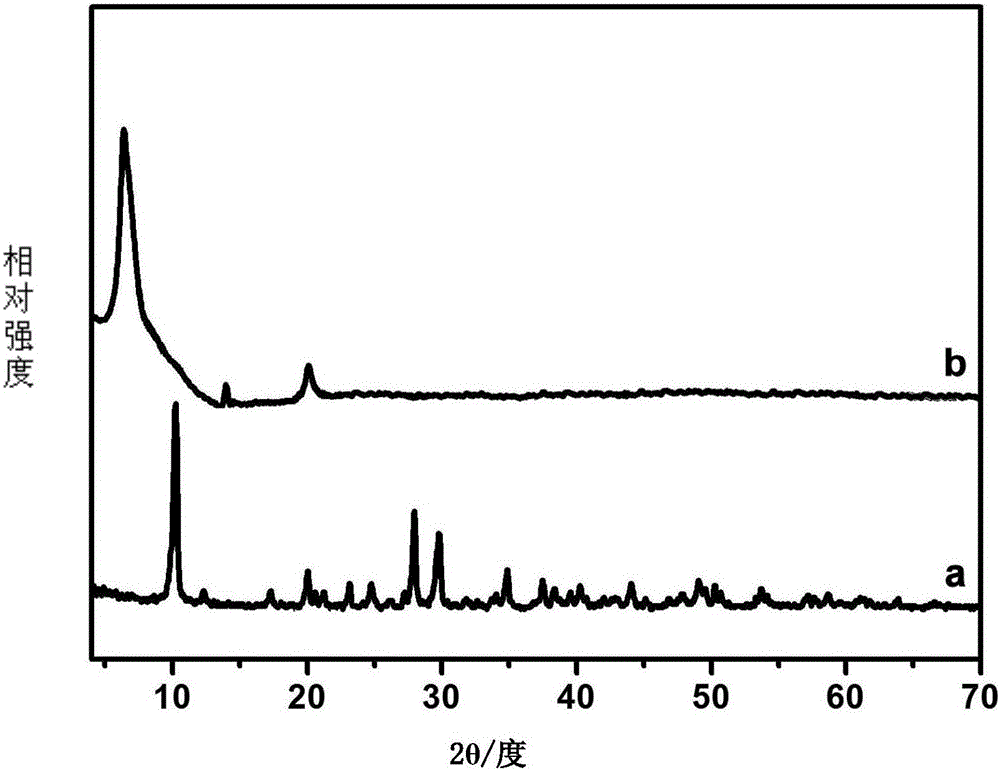

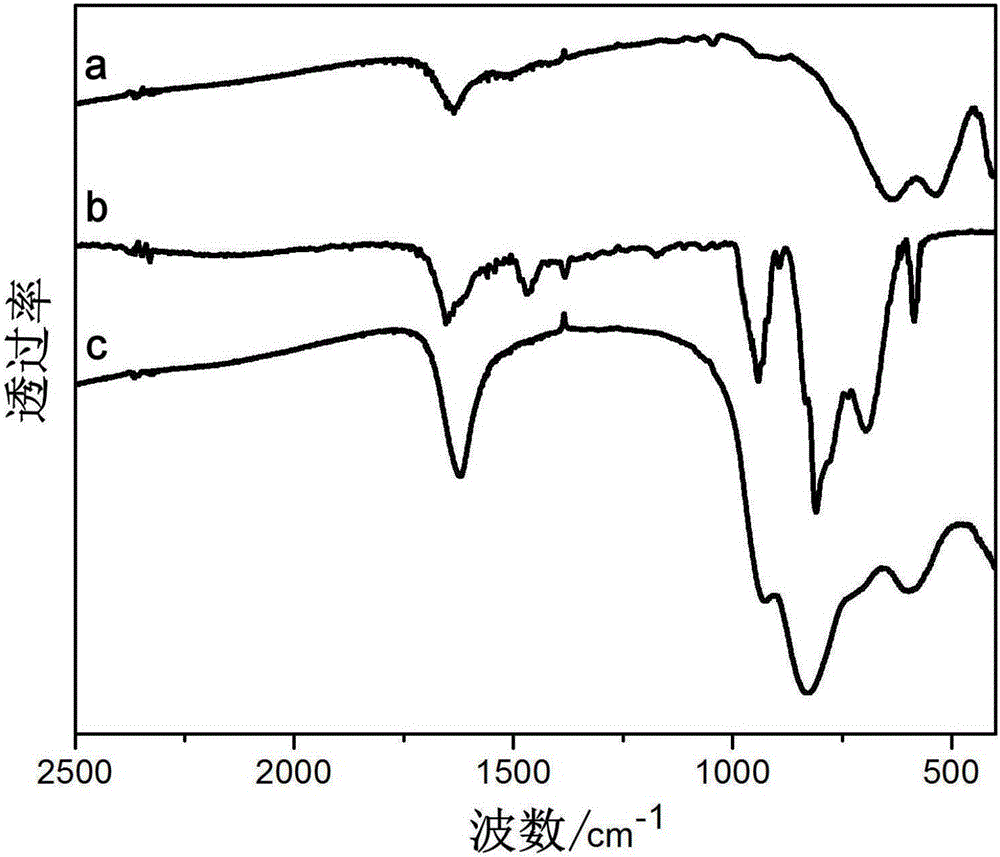

Method used

Image

Examples

Embodiment 1

[0026] a. Take 0.1molEu(NO 3 ) 3 ·6H 2 O was dissolved in 100ml deionized water to obtain a salt solution; 0.05mol KOH was dissolved in 100ml deionized water to obtain an alkali solution; under stirring conditions, the alkali solution was slowly added dropwise to the salt solution, and stirred at 40-80°C for 12 hours after the addition was completed , and then the system was heated to reflux for 24h, centrifuged and washed to obtain the interlayer anion as NO 3 - , the laminate trivalent rare earth metal cation is Eu 3+ The layered rare earth hydroxides, whose chemical formula is Eu 2 (OH) 5 NO 3 ;

[0027] b. Disperse 3 g of the layered rare earth hydroxide prepared in step a in 150 ml of deionized water;

[0028] c. Configure Na 9 wxya 10 o 36 32H 2 O dilute solution, the concentration is 0.05M;

[0029] d. drop the dilute solution prepared in step c into the layered rare earth hydroxide suspension prepared in step b, Na 9 wxya 10 o 36 32H 2 The number of mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com