Method and system for carrying out automatic solid-liquid continuous washing and separation

An automatic, solvent-washing technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve problems such as increasing energy consumption, increasing production costs of enterprises, and difficulty in washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

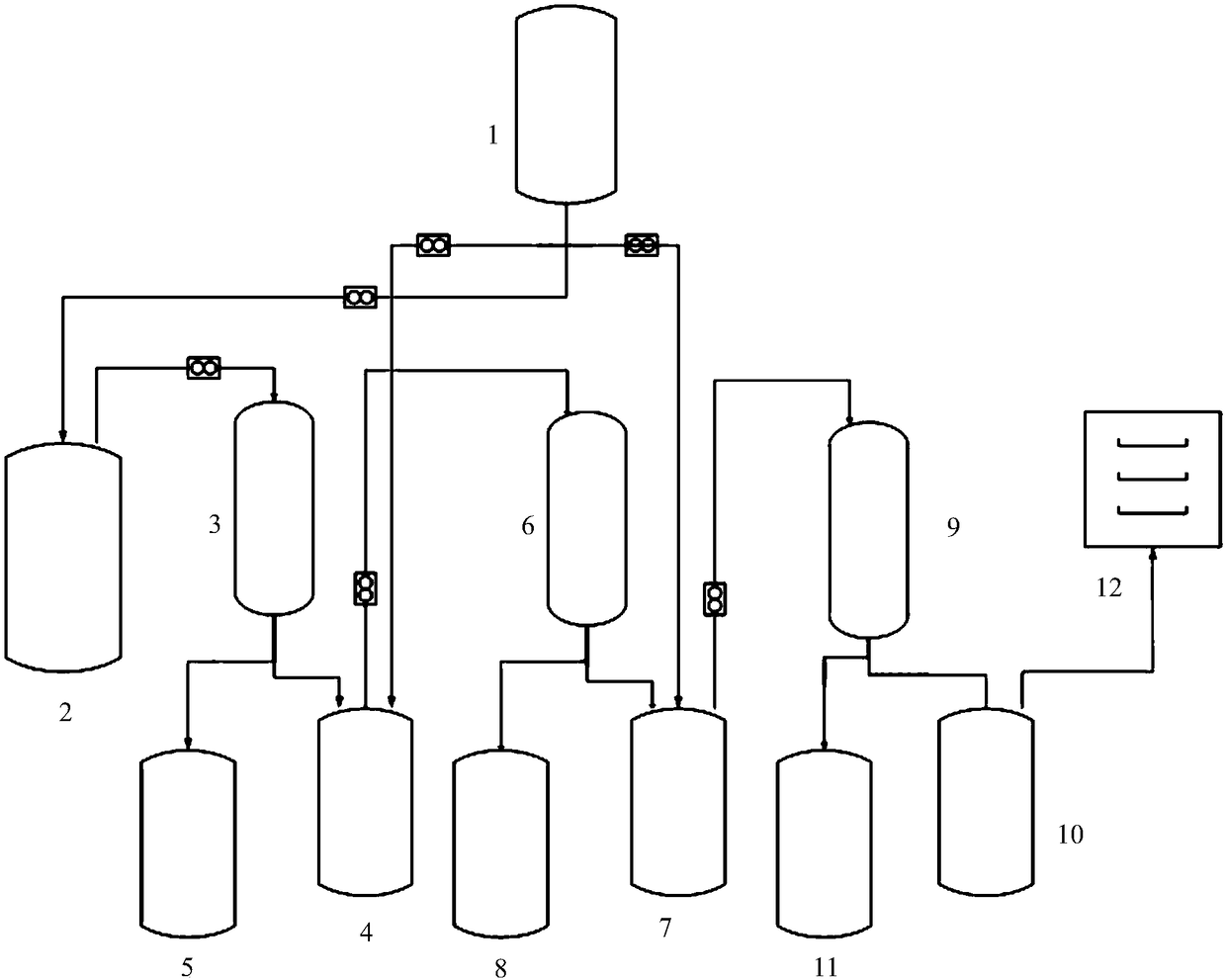

preparation example Construction

[0040] In some embodiments, the preparation method specifically includes:

[0041] (1) placing the washing solvent in the first storage mechanism, and keeping the temperature of the washing solvent at the set temperature;

[0042] (2) Place the original solid slurry to be processed in the second storage mechanism, keep the temperature of the original solid slurry at a set temperature, and use an automatic flow control unit to input the washing solvent according to a set ratio In the original solid slurry, a first mixed liquid is obtained;

[0043] (3) input the first mixed liquid into the first separation or filtration assembly, and keep the temperature of the first separation or filtration assembly at the set temperature, and separate to obtain liquid phase and solid slurry;

[0044] (4) placing the liquid phase obtained in step (3) in the fourth storage mechanism, and keeping the temperature of the liquid phase at a set temperature;

[0045] (5) Place the solid slurry obta...

Embodiment 1

[0097] In this embodiment, the preparation of powdered magnesium hydroxide by magnesium chloride is taken as an example to describe the device and its usage method in the present invention.

[0098] 1. the solid content obtained by magnesium chloride and sodium hydroxide reaction is 10% reaction feed liquid (which contains magnesium hydroxide product and sodium chloride impurity, will contain sodium chloride impurity in the magnesium hydroxide product if not through washing ) enters the first ceramic membrane module 3 after being diluted with the washing solvent and slurry according to 5:1, wherein the solid slurry enters the third storage tank 4 through the solid discharge port, and the liquid enters the fourth storage tank through the liquid discharge port 5. The process can be operated at room temperature (25°C).

[0099] 2. Dilute the magnesium hydroxide slurry in the third storage tank 4 by 5 times with water, dissolve the sodium chloride in water, and continue to send th...

Embodiment 2

[0103] 1. the solid content obtained by reacting magnesium chloride and sodium hydroxide is 5% reaction feed liquid (which contains magnesium hydroxide product and sodium chloride impurity, if not through washing will contain sodium chloride impurity in the magnesium hydroxide product ) enters the first filter assembly through the metering pump, wherein the solid slurry enters the third storage tank 4 through the solid discharge port, and the liquid enters the fourth storage tank 5 through the liquid discharge port, and an automatic temperature control system is used to keep the raw material in the second The temperature of the storage tank 2, the first storage tank 1 of the washing solvent, the first filter assembly, the third storage tank 4, and the fourth storage tank 5 is 50°C;

[0104] 2. Dilute the magnesium hydroxide feed liquid in the third storage tank 4 with water 20 times, make the sodium chloride therein dissolve in water, and continue to send the diluted magnesium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com