Wood plate grinding device

A technology of wood boards and pedals, which is applied in the field of wood board processing, can solve the problems of low work efficiency, high equipment failure, and debris clogging, and achieve the effect of accelerating the screening speed, low equipment failure rate, and not easy to be clogged with debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

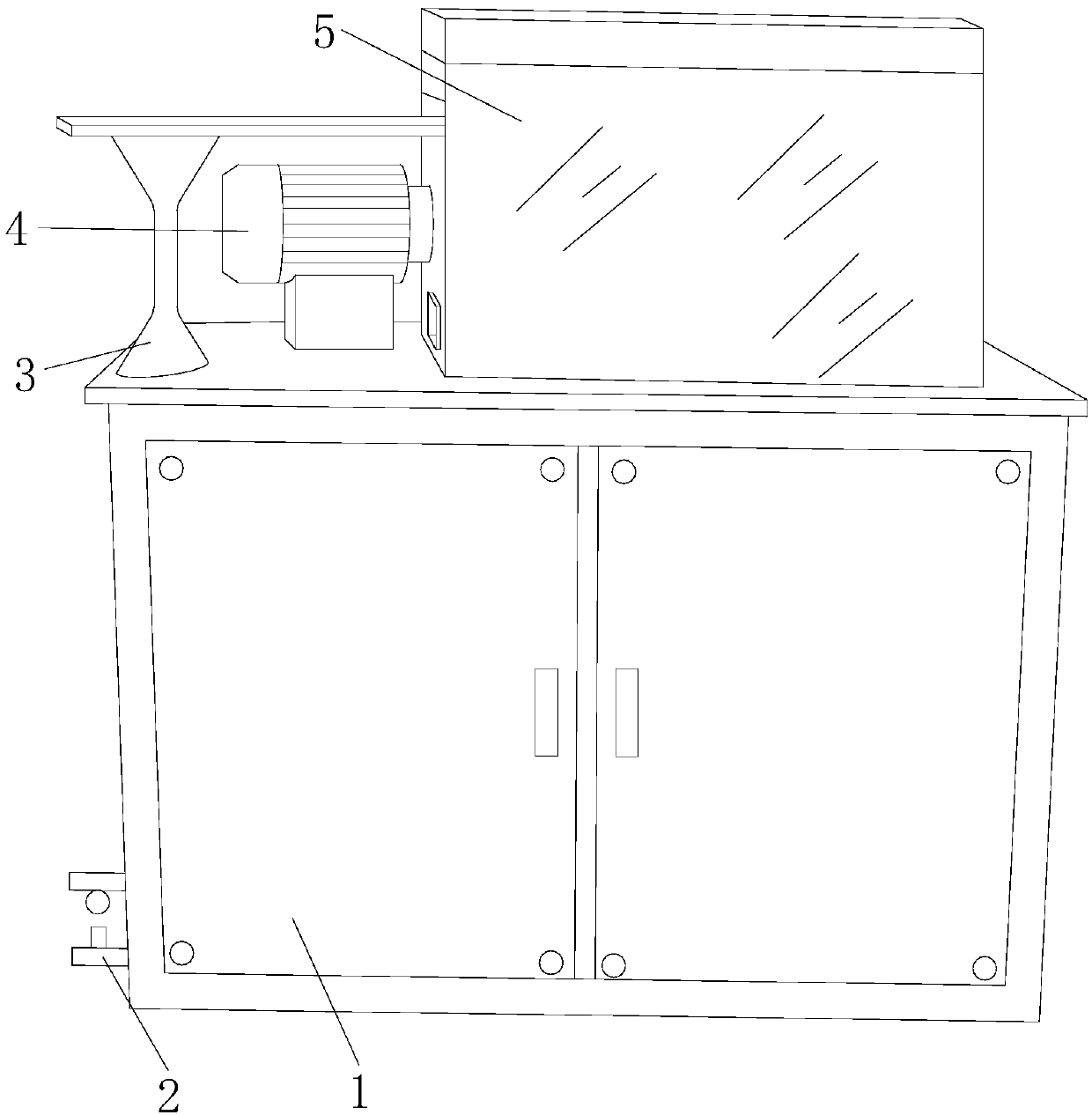

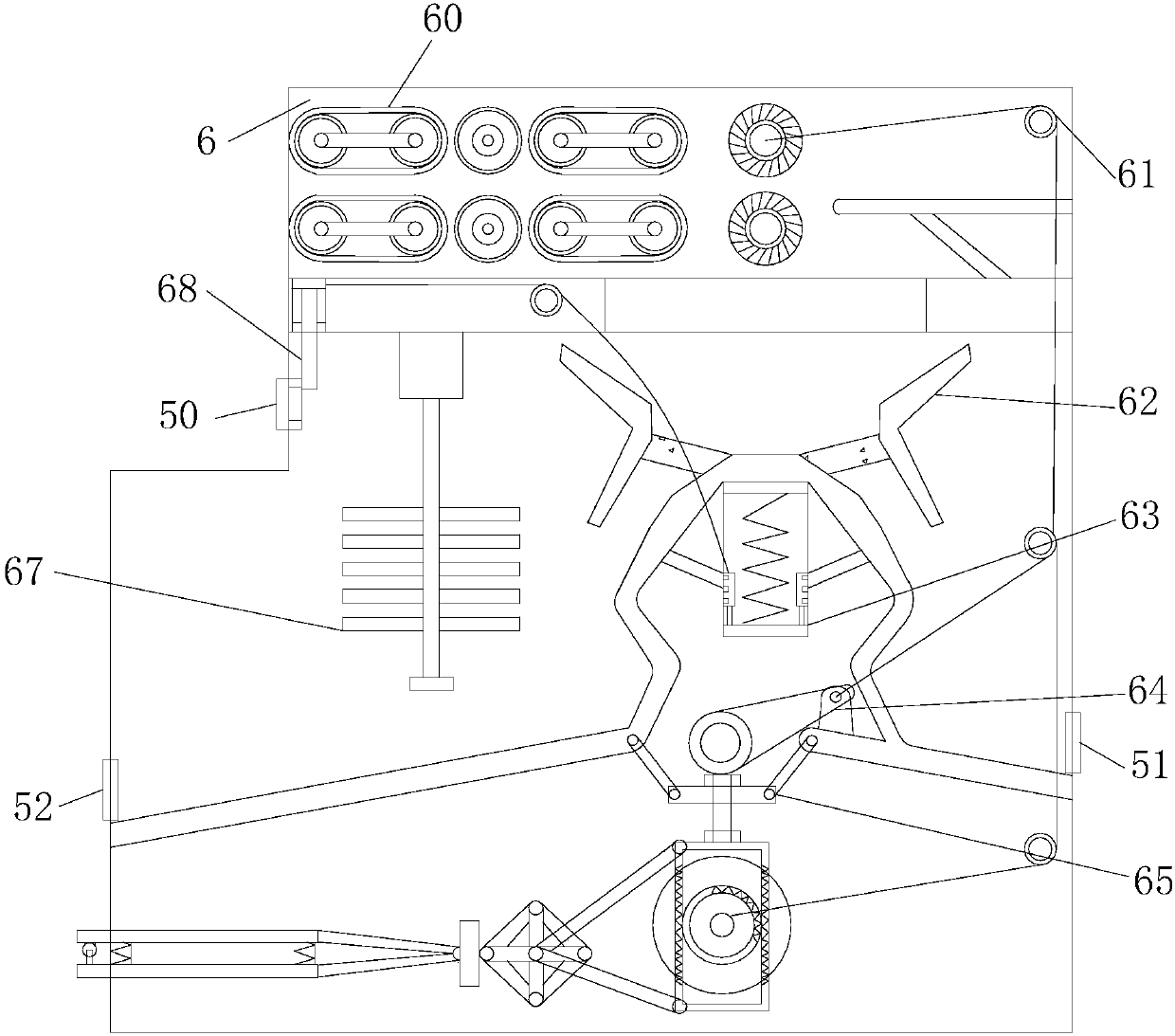

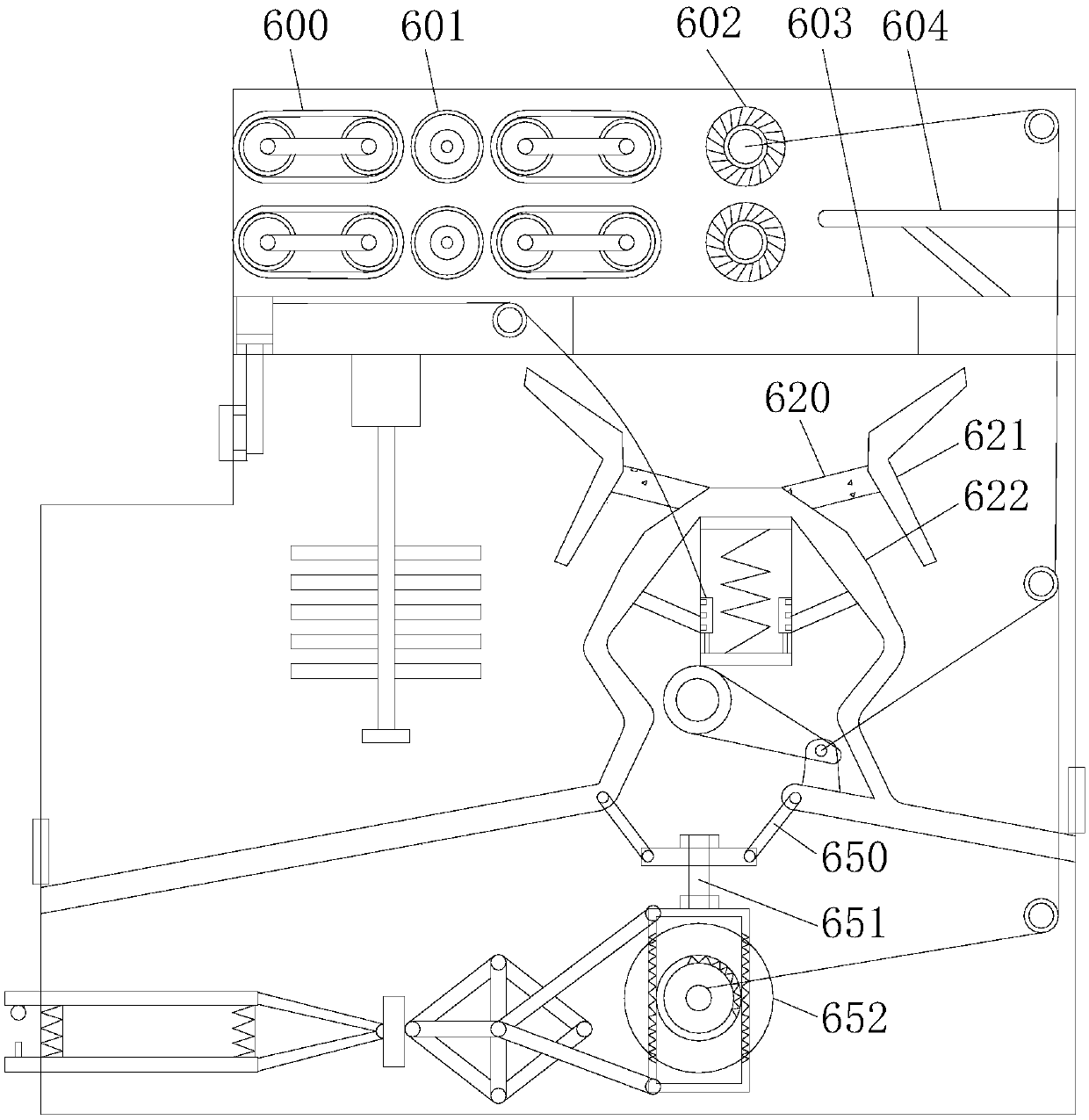

[0021] see Figure 1-Figure 4 , the present invention provides a wood board grinding device: its structure includes a box frame 1, a pedal 2, a support plate 3, a motor 4, a grinding visible frame 5, and a grinding device 6, and the pedal 2 is arranged at the lower left corner of the box frame 1, The bottom of the support plate 3 is glued to the upper surface of the upper left corner of the box frame 1, and the end of the support plate 3 away from the pedal 2 is embedded in the polished visible frame 5. The support plate 3 is adjacent to the motor 4, and the motor 4 Fixedly connected to the upper end surface of the box frame 1, located in the middle of the support plate 3 and the grinding visible frame 5, the motor 4 is engaged with the grinding visible frame 5, the motor 4 is electrically connected to the grinding device 6, and the pedal 2 It is composed of buckle plate 20, spring pressure plate 21, clamp rod 22, square frame 23, and bite frame 24. The buckle plate 20 and spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com