Six-way switching ball valve

A technology of three-way ball valves and ball valves, applied in multi-way valves, valve details, valve devices, etc., can solve problems such as limited application occasions, and achieve the effects of avoiding sliding friction, smooth meshing, and no jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

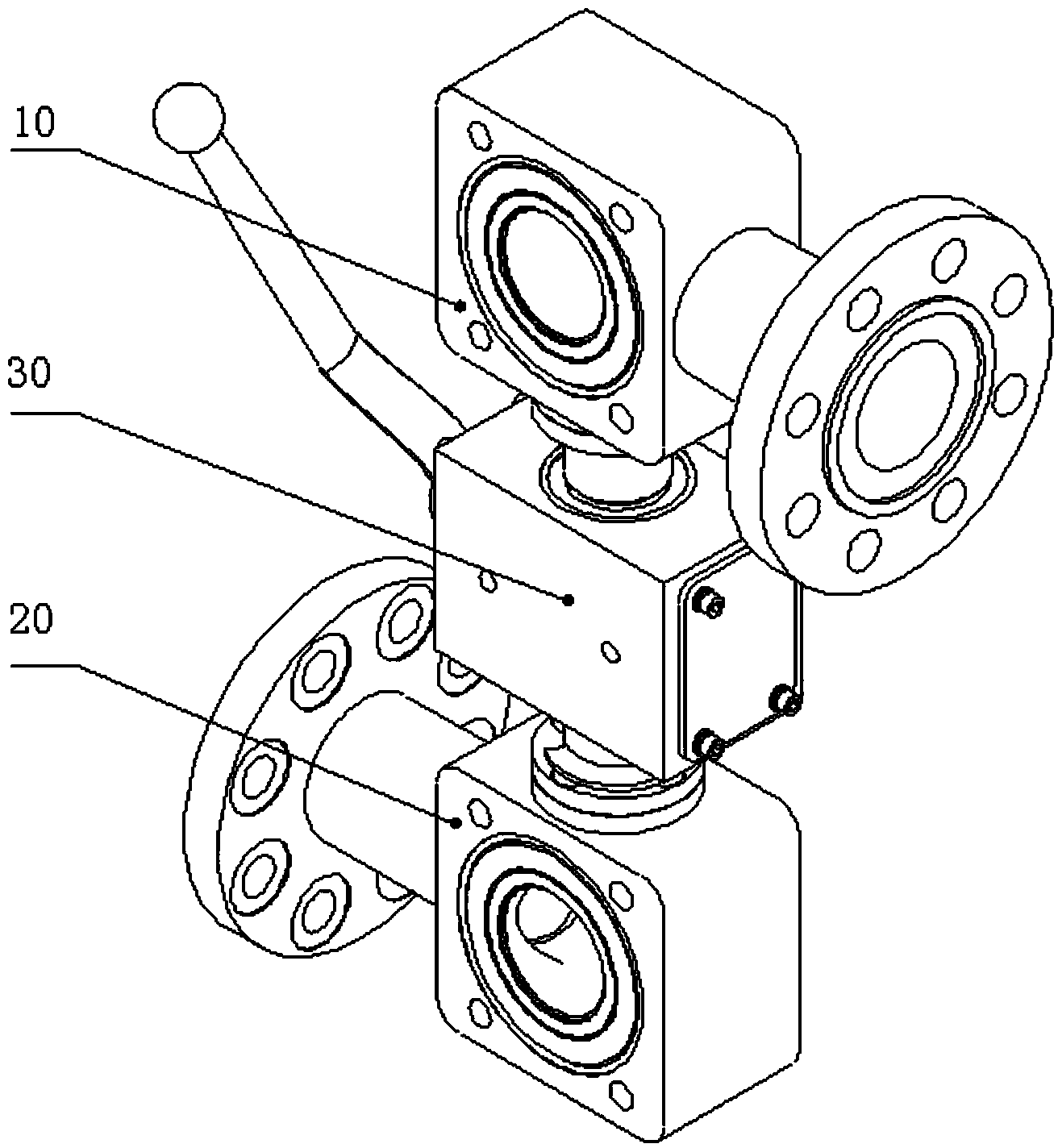

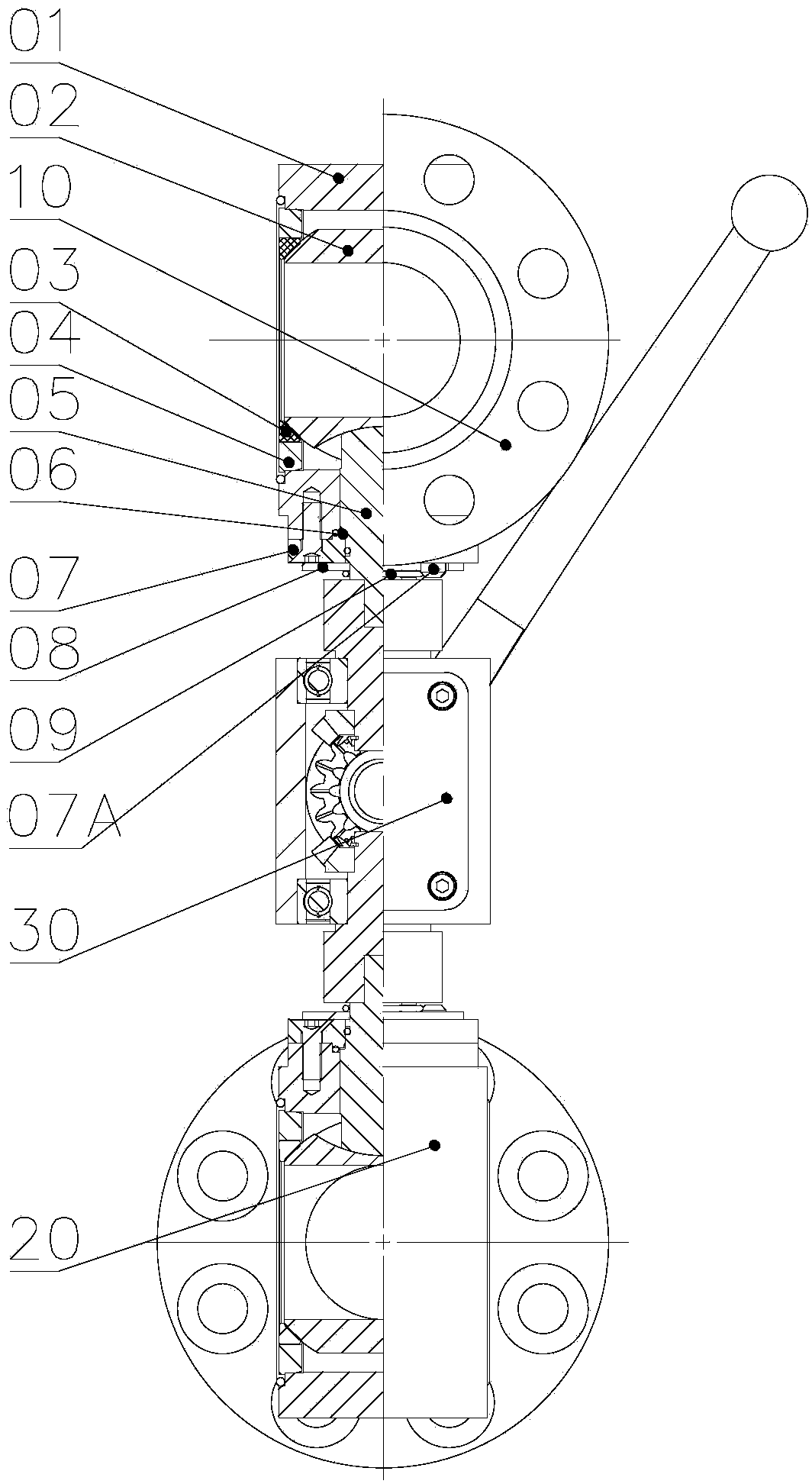

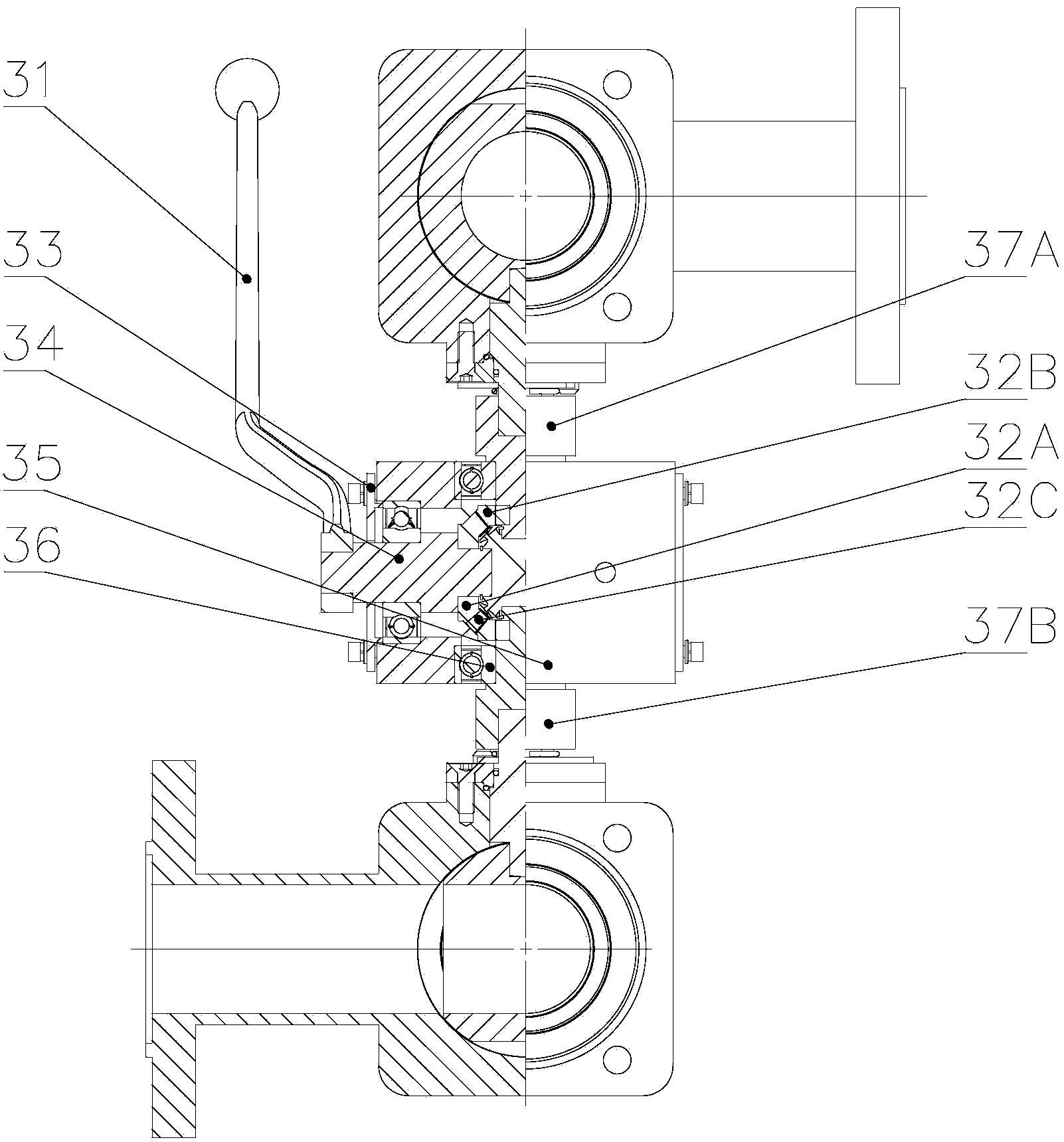

[0032] Such as figure 1 , figure 2 , image 3 As shown, the embodiment of the present invention consists of an upper three-way ball valve 10, a lower three-way ball valve 20 and a drive conversion mechanism 30;

[0033] A. The structures and components of the upper three-way ball valve 10 and the lower three-way ball valve 20 are identical, and each consists of a valve body 01, a ball body 02, a sealing gasket 03, a sealing retaining ring 04, a rotating shaft 05, a thrust ring 06, Composed of flange gland 07, rotating block 08, and steel wire retaining ring 09;

[0034] Such as Figure 4 As shown, the valve body 01 has a circular through hole 01A through the front and rear end faces. The front and rear end faces of the valve body are used as the on-site pipeline installation surface. An integrated connection flange 01C, the flow pipe 01B communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com