Sheet splicing device

A splicing device and sheet technology, applied in the direction of adhesive application device, wooden veneer joint, glue container, etc., can solve the problems of reducing the splicing strength of plank wood, uneven glue coating, and unstable bonding of the splicing surface, etc. , to achieve the effect of stable transmission and improved rotation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further detailed explanation through specific implementation mode below:

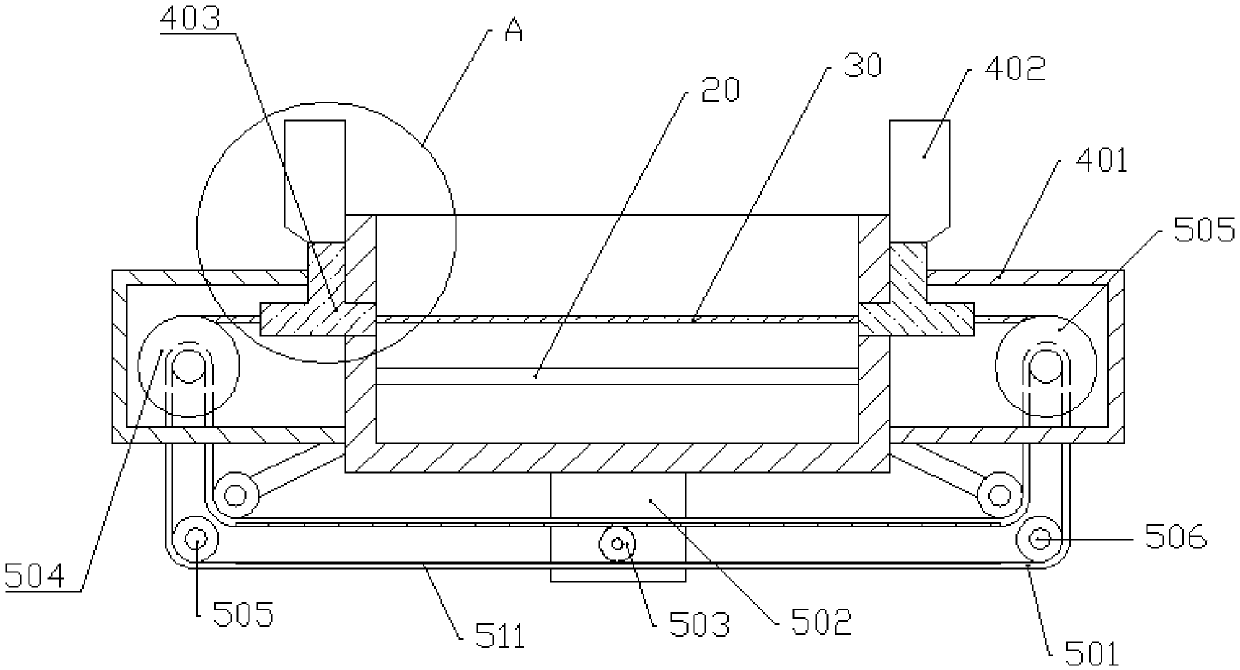

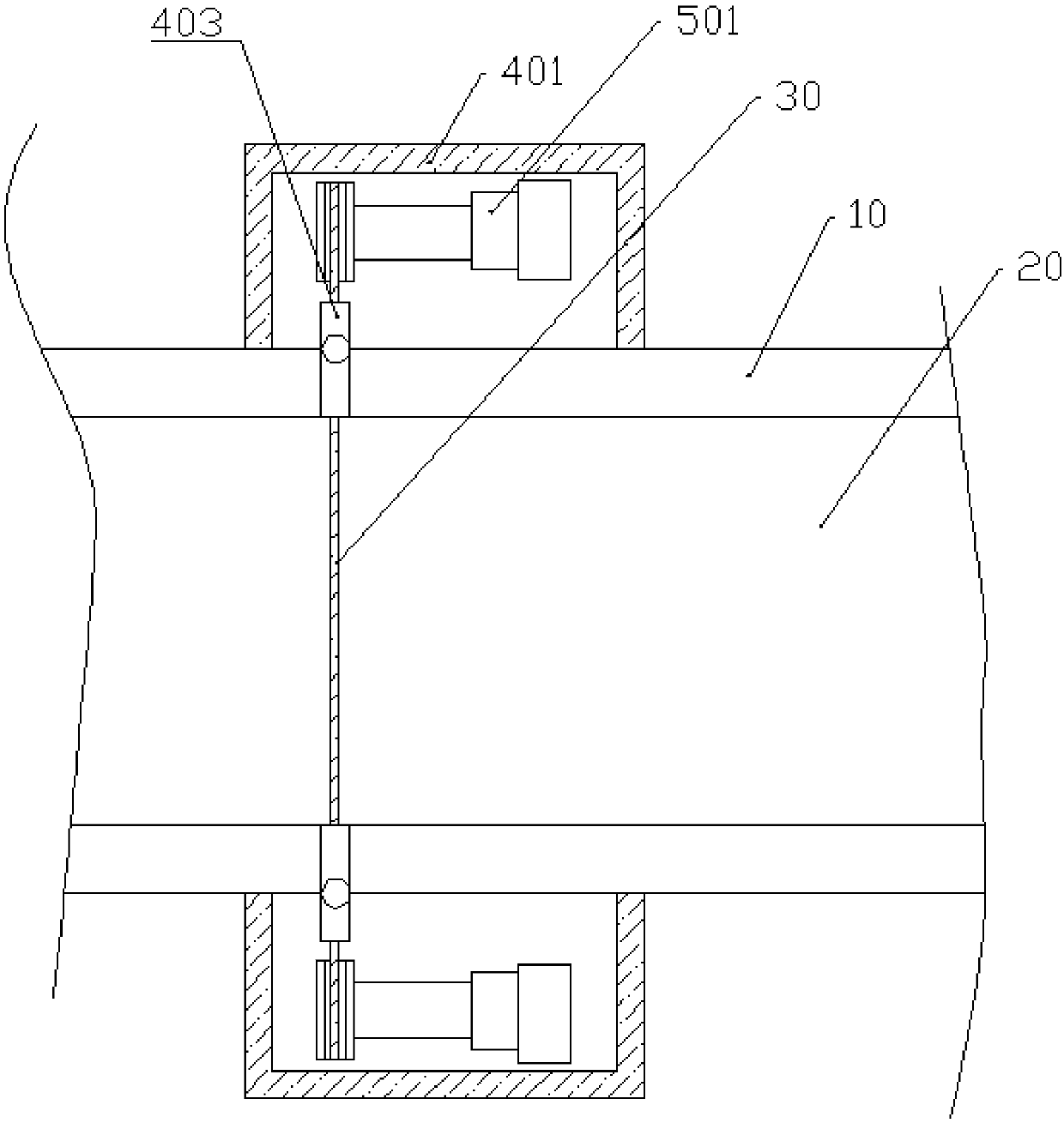

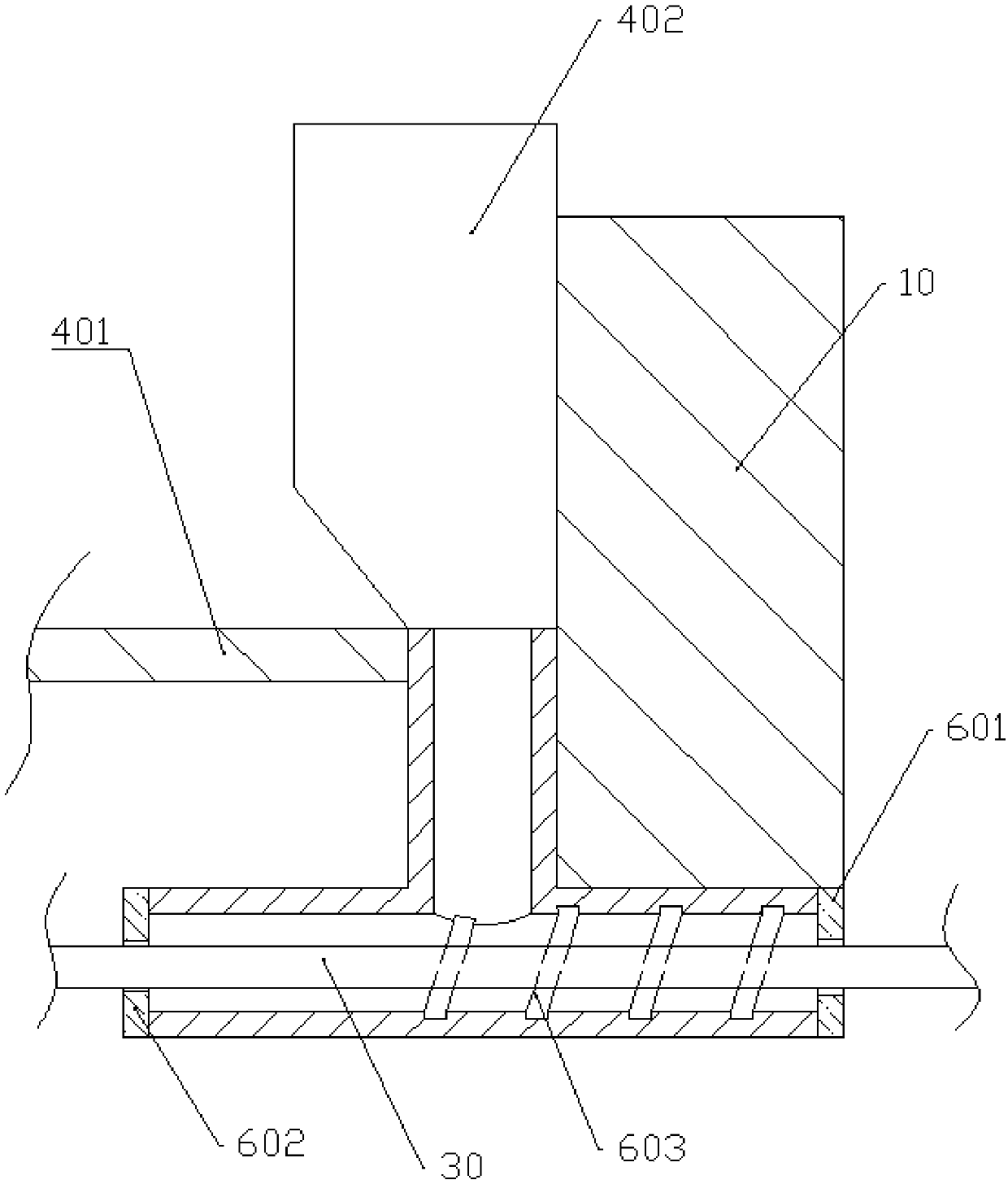

[0020] The reference signs in the accompanying drawings of the description include: frame 10, conveyor belt 20, glue-coated rope 30, installation box 401, glue storage box 402, glue-coated pipe 403, transmission belt 501, transmission gear 511, motor 502, driving wheel 503, the first A driven wheel 504 , a second driven wheel 505 , a first idler wheel 506 , a second idler wheel 507 , a first block 601 , a second block 602 , and a guide groove 603 .

[0021] The embodiment is basically as attached figure 1 , attached figure 2 And attached image 3 Shown: a sheet splicing device, including a conveyor belt 20, a frame 10, a gluing mechanism and a power mechanism, and the conveyor belt 20 is horizontally installed on the frame 10.

[0022] The gluing mechanism includes an elastic gluing rope 30 and two gluing units, the gluing unit is welded on the frame 10, and the two gluing units are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com