Filter press filter cake crushing system and method

A crushing system and filter press technology, applied in grain processing, etc., can solve the problems of high moisture, high viscosity, and sticking into blocks, so as to prolong the conveying time, reduce the probability of accumulation, and avoid the effect of accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

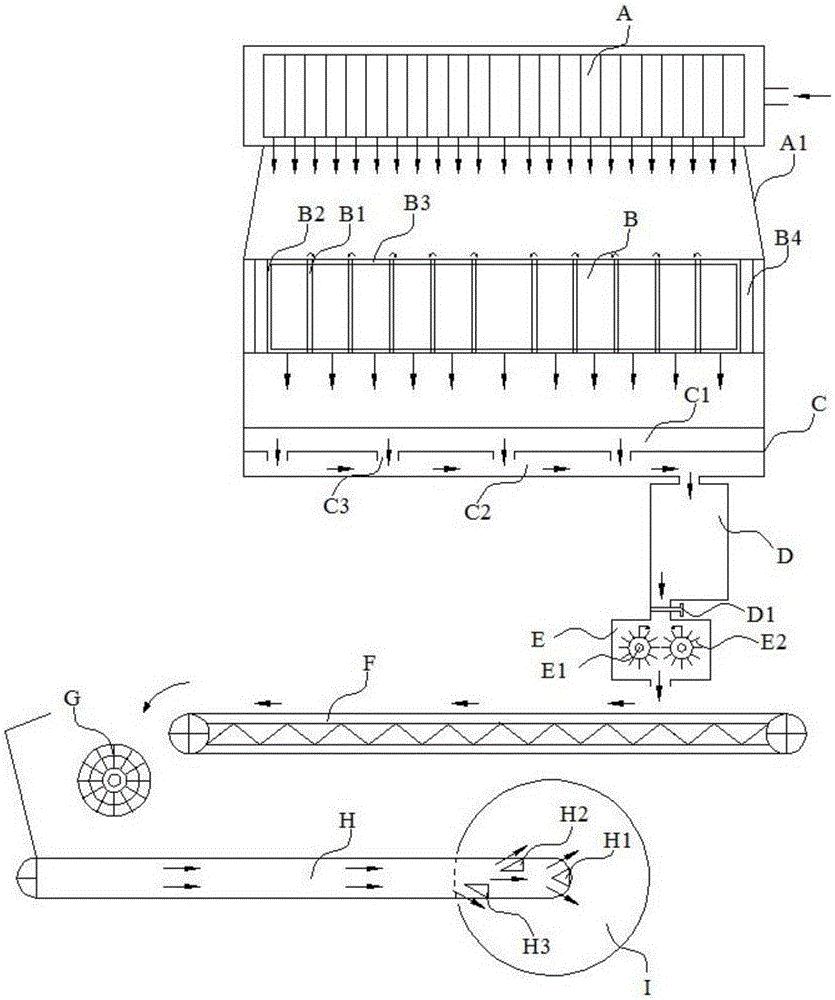

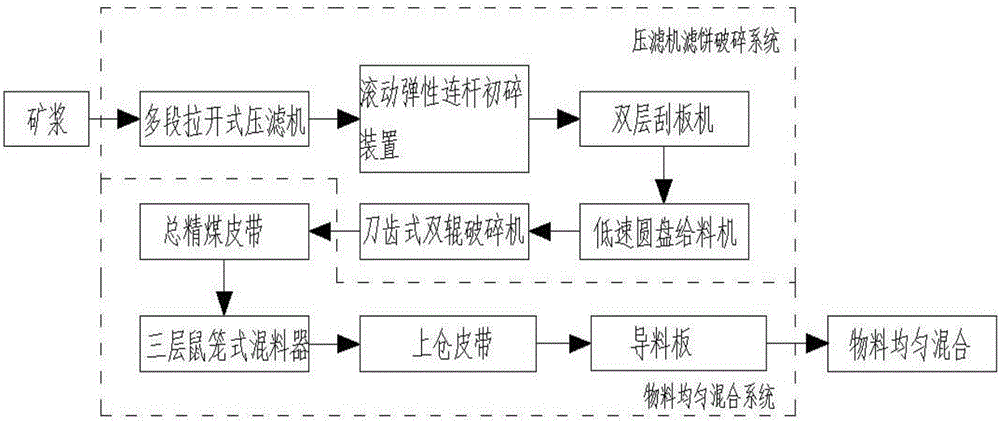

[0030] Embodiment. The present invention is applied to clean coal pressure filter coal slime cake and heavy separation coarse coal uniform mixing system

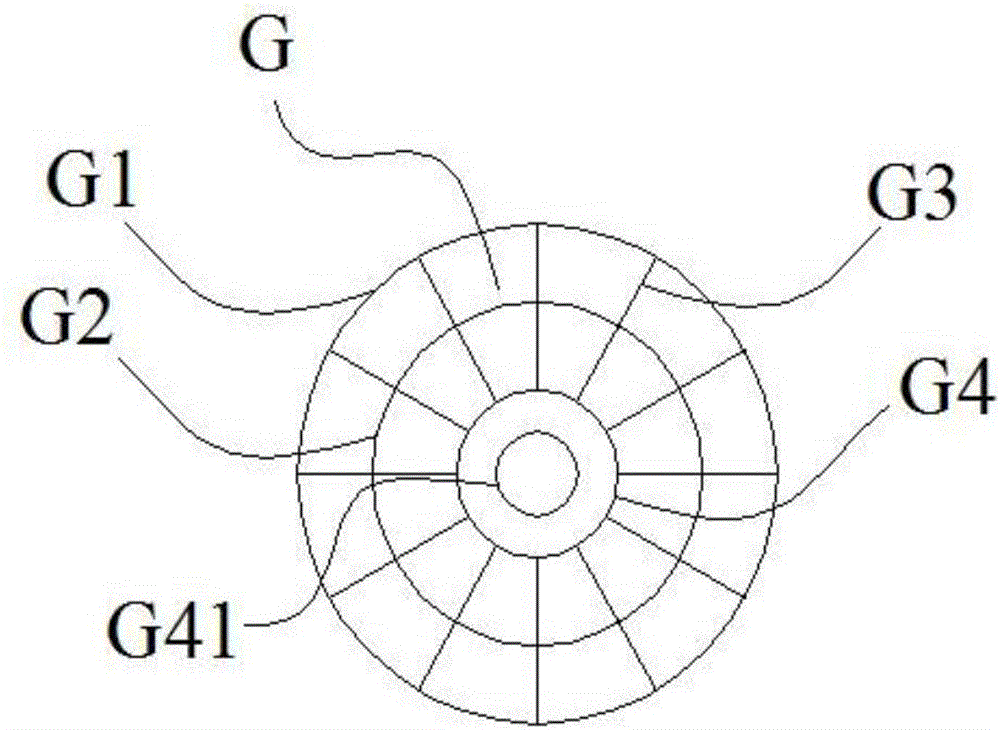

[0031] Such as Figure 1-4 , the present invention is applied to the uniform blending system of clean coal press filter slime cake and heavy separation coarse coal, and the present invention includes a multi-stage pull-off filter press A, a rolling elastic connecting rod primary crushing device B, and a double-layer scraper machine C , Low-speed disc feeder D and knife-toothed double-roller crusher E. The crushed material of the present invention enters the uniform mixing system, which includes the total clean coal belt F, the three-layer squirrel cage mixer G, the upper bin belt H and the material guide plate; the following are described one by one:

[0032] 1. A filter cake crushing system and method for a filter press

[0033] (1), multi-stage pull-off filter press

[0034] The ore pulp enters the multi-stage pull-off ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com