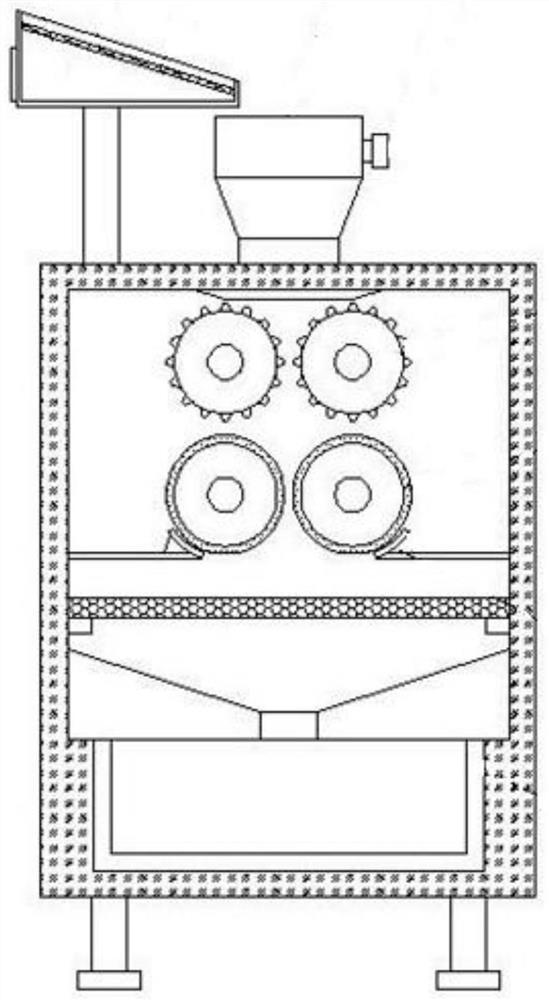

Flour mill for wheat processing

A milling machine and wheat technology, applied in grain processing, etc., can solve the problems of wheat feeding blockage, wheat flour production efficiency impact, wheat milling efficiency reduction, etc., to prevent the reduction of rolling efficiency, reduce the probability of accumulation, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

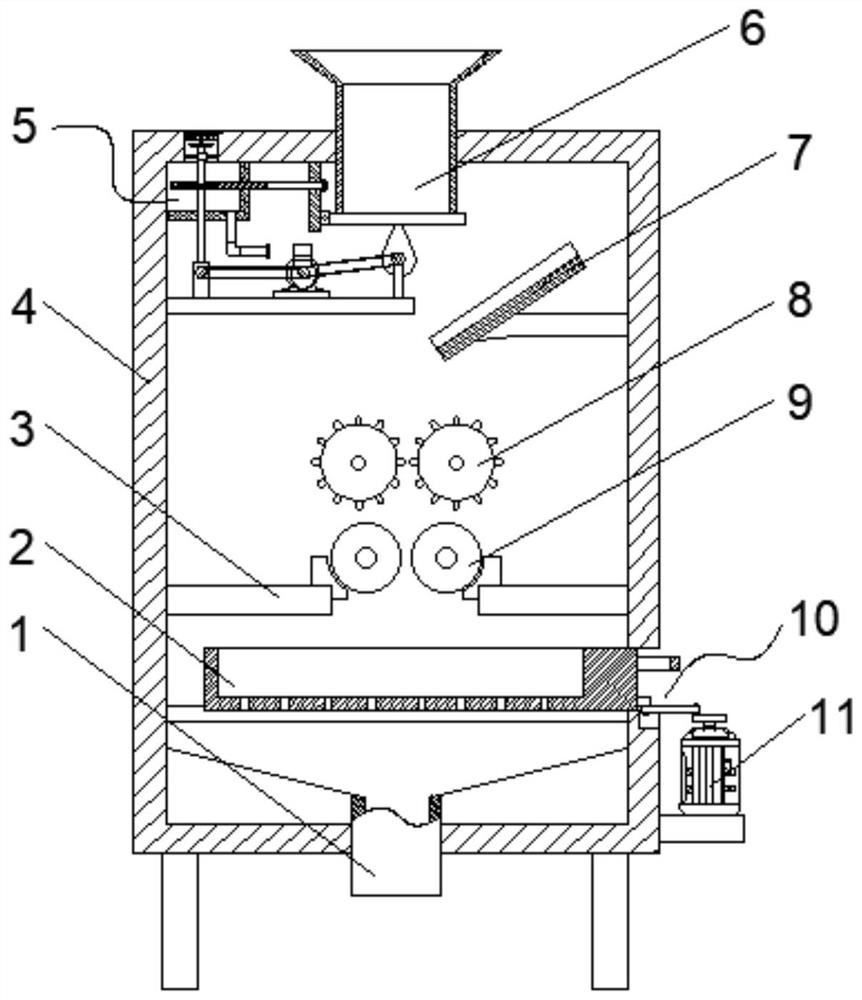

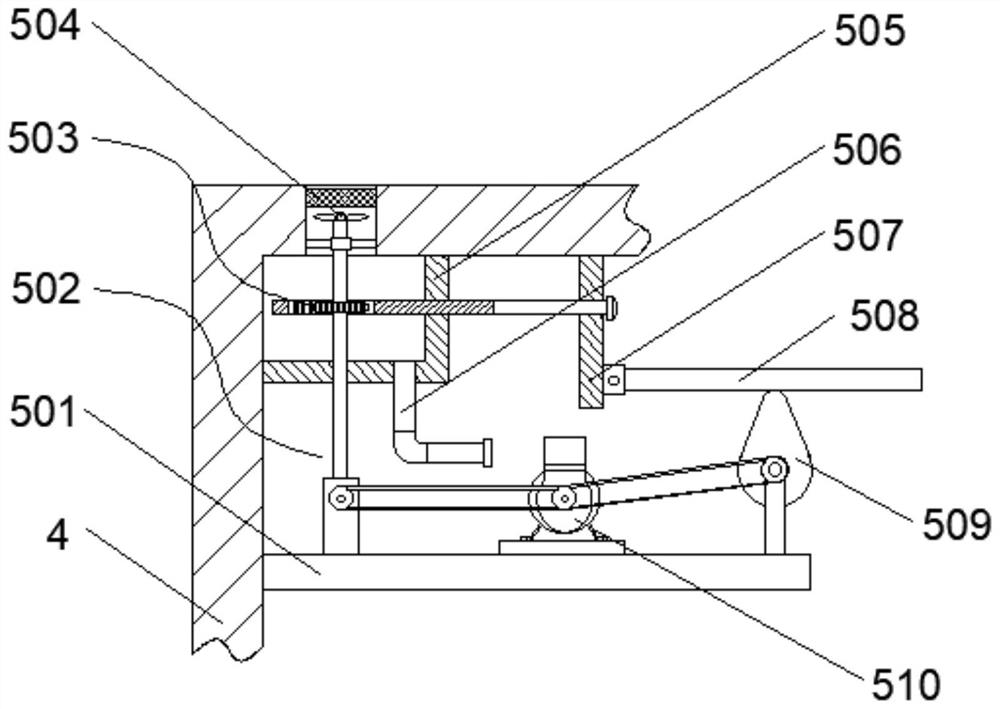

[0035] see image 3 , Figure 4 with Figure 5 As shown, the above-mentioned speed regulating mechanism 5 includes a first limiting plate 501 and a second limiting plate 507 fixedly connected with the installation box 4, the top of the first limiting plate 501 is provided with a second driving motor 510, and the second driving One side of the motor 510 is provided with a cam 509, the output end of the second driving motor 510 is connected to the cam 509 through a belt and a pulley, the bottom of the second limiting plate 507 is hinged with a shielding plate 508, and the cam 509 is slidingly connected to the shielding plate 508 , the output end of the feeding pipe 6 abuts against the baffle plate 508, and the cam 509 is rotated to cause the baffle plate 508 to rotate in a gap, so as to facilitate the speed regulation of the wheat output in the feeding pipe 6 and prevent the wheat from reaching the material guide too quickly. At the plate 7, the other side of the second drive mo...

Embodiment 2

[0038] see Image 6 with Figure 7 As shown, the above-mentioned transmission mechanism 10 includes a turntable 1003 fixedly connected to the output end of the first drive motor 11, the surface of the turntable 1003 is hinged with a transmission rod 1002, and one end of the transmission rod 1002 is hinged with the rotating seat through a bolt 1001, and the rotating seat is connected with the filter The plate 2 is fixedly connected, the bottom end of the bolt 1001 is threadedly connected with a nut, and the position corresponding to the outer wall of the installation box 4 and the bolt 1001 is provided with a rotation groove 1004; the rotation of the turntable 1003 drives the transmission rod 1002 to move, so that the transmission rod 1002 is opposite to the filter plate 2 The reciprocating push-pull operation is carried out, so that the filter plate 2 filters the rolled wheat flour, and recycles the unqualified wheat flour for rolling again.

[0039] The rotation of the turnt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com