Low consumption highly effective sludge drying method

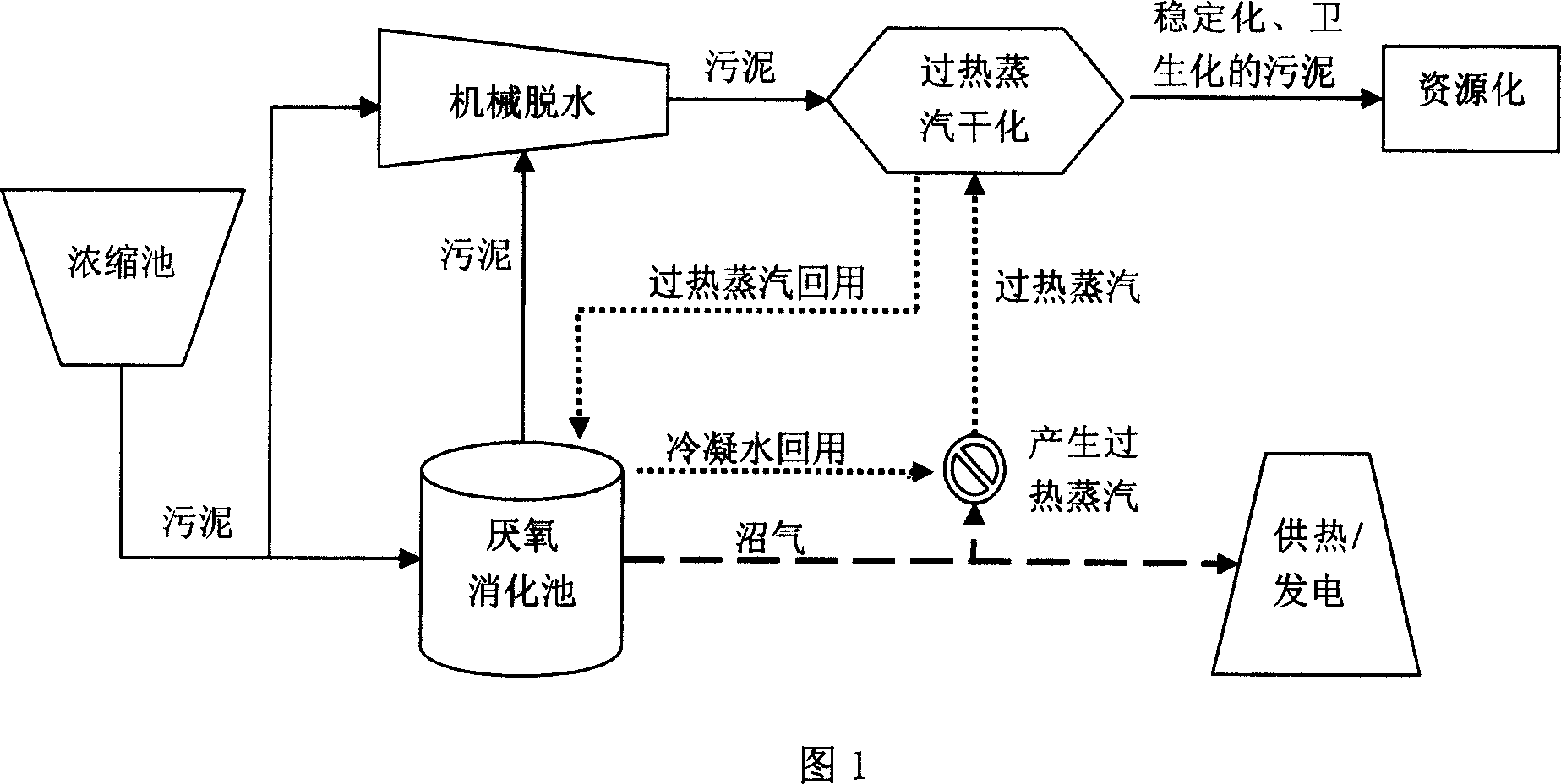

A sludge drying and high-efficiency technology, which is applied in chemical instruments and methods, sludge treatment, sludge treatment, etc., can solve the problems of low thermal efficiency, high odor concentration, sludge cementation and wall sticking, etc., and achieve high thermal efficiency, Reduce energy consumption and avoid explosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A sewage treatment plant with a scale of 100,000t / d, using this technology, the proportion of concentrated sludge entering the anaerobic digester is 100%, and the daily production of biogas is 5000m 3 , All used to generate superheated steam (combustion tail gas is used to generate steam, and combustion is used to superheat the steam), the thermal efficiency can reach 80%; the moisture content of digested sludge after dehydration is about 75%, and it enters the superheated steam drying system. The superheated steam drying heat efficiency is 90%, the outlet sludge moisture content is 60%, and the energy balance is calculated as follows. The entire system can realize energy self-balance without additional heating, only power consumption, low energy consumption, and high efficiency. The dried export sludge can be used for composting or making synthetic fuel, making full use of the organic matter in it.

[0027]

Embodiment 2

[0029] A sewage treatment plant with a scale of 30,000t / d, all the concentrated sludge enters the medium temperature anaerobic digestion tank, with a daily production of 1,050m methane 3 , All used to generate superheated steam, the thermal efficiency can reach 80%; the moisture content of the digested sludge after dehydration is about 75%, and it enters the superheated steam drying system, the superheated steam drying thermal efficiency is 90%, and the outlet sludge moisture content is 10%. The energy balance is as follows. In addition to biogas combustion for heating, the entire system needs to burn about 8t of coal (coal combustion efficiency is calculated at 30%). If the unit price of coal is 200 yuan, the treatment cost per ton of wet mud is about 50 yuan. The dried export sludge becomes granular and can be directly used for incineration to generate electricity. The calorific value of the dried sludge is calculated at 10MJ / kg, and the daily power generation capacity is 4000 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com