Urban sludge treating method and equipment

A technology of municipal sludge and treatment method, which is applied in the direction of sludge treatment, sludge treatment, biological sludge treatment, etc., can solve the problems of low efficiency and poor effect of sludge treatment, shorten the digestion time, simplify the dehydration process, The effect of improving the dehydration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

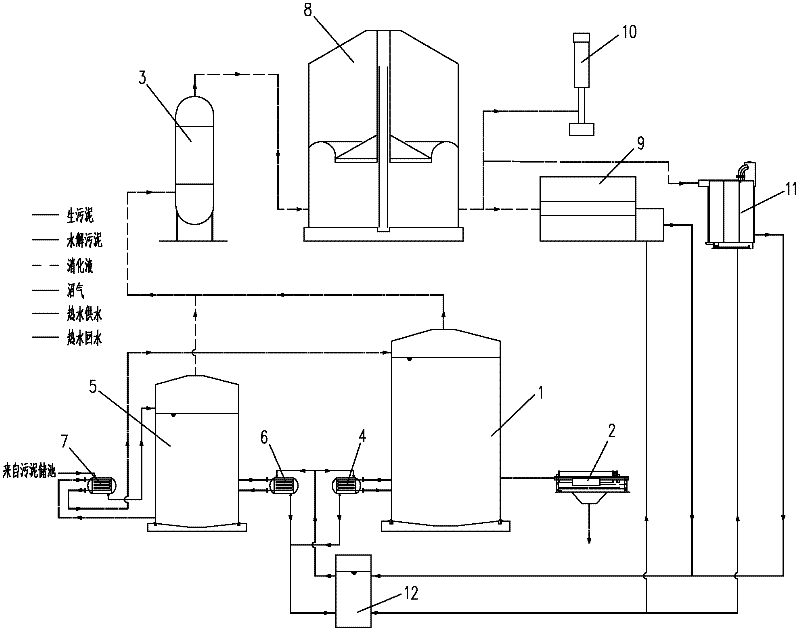

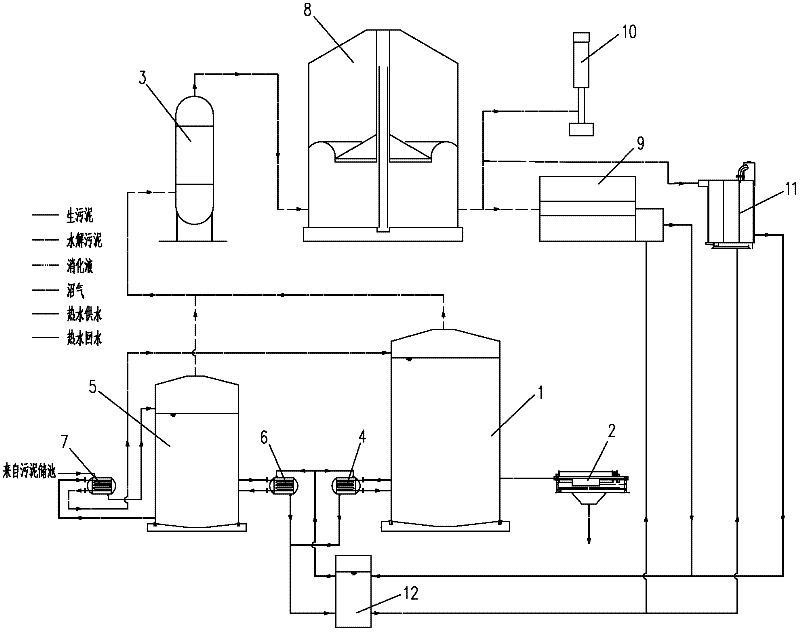

[0020] The primary sludge and excess sludge of the sewage treatment plant are mixed and thickened, and the sludge volume is 250 tons / day (water content 96%), and the dry solid content is 10,000 kg / day. Use municipal sludge treatment method of the present invention to process, comprises the steps:

[0021] In the first step, the sludge that needs to be treated, such as primary sludge and excess sludge, is first pretreated (pretreatment is the same as the prior art and includes homogeneity, etc.) to form concentrated sludge (about 92% moisture content), concentrated sludge The sludge is firstly heated by the heat exchanger 7 and the temperature rises to 55°C; then, the high-temperature concentrated sludge is pumped into the 3 In the cylindrical high-temperature hydrolysis acidification reactor 5, the high-temperature hydrolysis acidification reaction is carried out. During this process, the high-temperature hydrolysis acidification reactor 5 is heated and kept warm by the heater...

Embodiment 2

[0033] The primary sludge and excess sludge of the sewage treatment plant are mixed and concentrated, and the sludge volume is 75 tons / day (water content 80%), and the dry solid content is 15,000 kg / day. Use municipal sludge treatment method of the present invention to process, comprises the steps:

[0034] In the first step, the pretreated concentrated sludge (water content 92%) is first heated by the heat exchanger 7 and the temperature rises to 50°C; then, the high-temperature concentrated sludge is pumped into a cylindrical high-temperature hydrolysis tank with an effective volume of 965.6m3 In the acidification reactor 5, the high-temperature hydrolysis acidification reaction is carried out. During this process, the heater 6 heats and keeps the temperature of the high-temperature hydrolysis acidification reactor 5 at 45°C to provide the heat required for anaerobic digestion. The pH value of the sludge in the hydrolytic acidification reactor 5 is controlled at 6.5, and the...

Embodiment 3

[0040] The primary sludge and excess sludge of the sewage treatment plant are mixed and thickened, and the sludge volume is 500 tons / day (water content 94%), and the dry solid content is 30,000 kg / day. Use municipal sludge treatment method of the present invention to process, comprises the steps:

[0041] In the first step, the pretreated concentrated sludge (with a water content of 92%) is first heated by the heat exchanger 7 and the temperature rises to 45°C; then, the high-temperature concentrated sludge is pumped into an effective volume of 761.3m 3 In the cylindrical high-temperature hydrolysis acidification reactor 5, the high-temperature hydrolysis acidification reaction is carried out. During this process, the high-temperature hydrolysis acidification reactor 7 is heated and kept warm by the heater 6, so that its temperature is kept at 55° C. to provide anaerobic digestion. required heat, the pH value of the sludge in the high temperature hydrolysis acidification react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com