Biological drying method for treating dewatered sludge of urban sewage plant

A technology of dewatering sludge and biological drying, which is applied in dehydration/drying/concentrated sludge treatment, biological sludge treatment, etc. It can solve the problems of bulky drying equipment, unsatisfactory drying effect, and poor ventilation effect. , to achieve a wide range of waste heat sources, shorten the biological drying time, and realize the effect of heat energy recovery and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

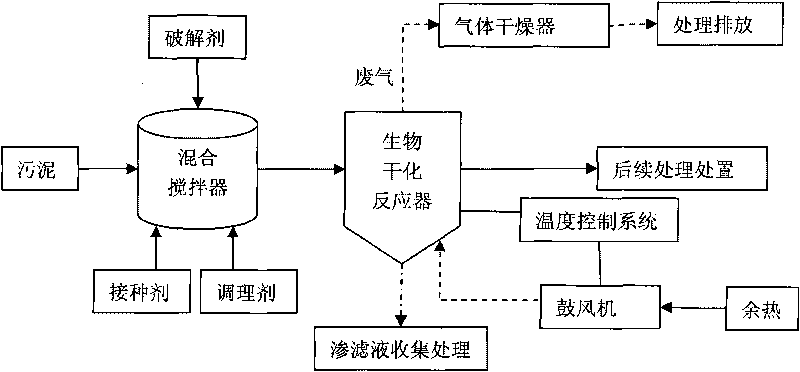

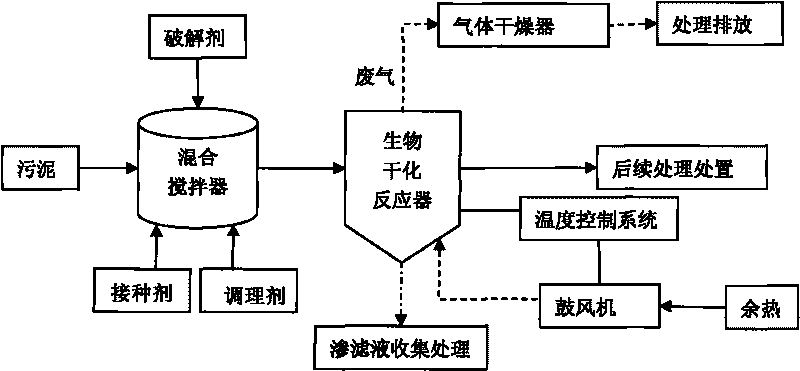

[0027] A biological drying treatment method for dewatered sludge from an urban sewage plant, the flow chart of the biological drying treatment when adding an inoculant for inoculation is as follows figure 1 As shown, the method steps are as follows,

[0028] (1) The moisture content of the dewatered sludge is 85-87%. Add lime with a ratio of 10% of the dry weight of the sludge to the sludge as an alkaline cracking agent, mix well, and the weight of the dewatered sludge added to the cracking agent accounts for the total weight of the mixture. 60% of;

[0029] (2) add broken straw again as conditioner, conditioner weight accounts for 35% of mixed material gross weight, adds compost clinker and inoculates as inoculant, and inoculant weight accounts for 5% of mixed material gross weight, makes mixed material moisture content 58-62%, the initial carbon-nitrogen ratio is 25-30:1;

[0030] (3) Stir the mixture evenly and place it in a biological drying reactor. The reactor volume i...

Embodiment 2

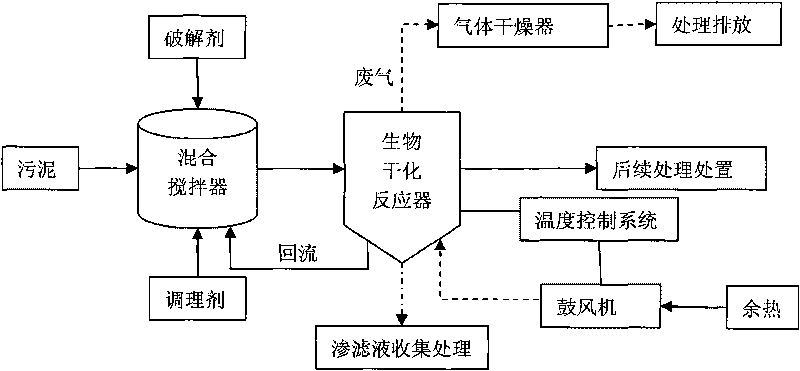

[0034] A small-scale project with a scale of 20t / d was established in a sewage treatment plant in Beijing, using a static warehouse-type biological drying reaction tank, intermittent stirring and turning, and waste heat ventilation pipes on the bottom of the warehouse. The flow chart of backflow inoculation with biological drying products is as follows: figure 2 As shown, the steps of the biological drying treatment method for dewatered sludge in urban sewage plants are as follows:

[0035] (1) The moisture content of the dewatered sludge is 80-85%. Add lime with a ratio of 10% of the dry weight of the dewatered sludge to the dewatered sludge as an alkaline cracking agent, mix well, and the weight of the dewatered sludge added with the cracking agent accounts for 55% of the total weight;

[0036] (2) Add broken stalks and sawdust as conditioners again, the conditioner weight accounts for 25% of the total weight of the mixture, wherein the proportion of broken straws is 15% o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com