Method using drying and incineration to treat sludge

A technology of sludge drying and disposal methods, applied in combustion methods, chemical instruments and methods, water/sludge/sewage treatment, etc. The effect of small equipment, low power consumption of the device and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

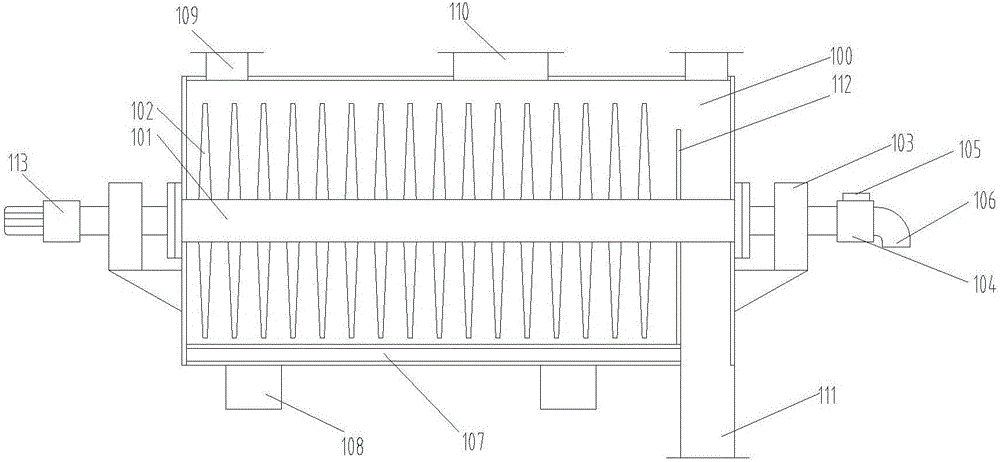

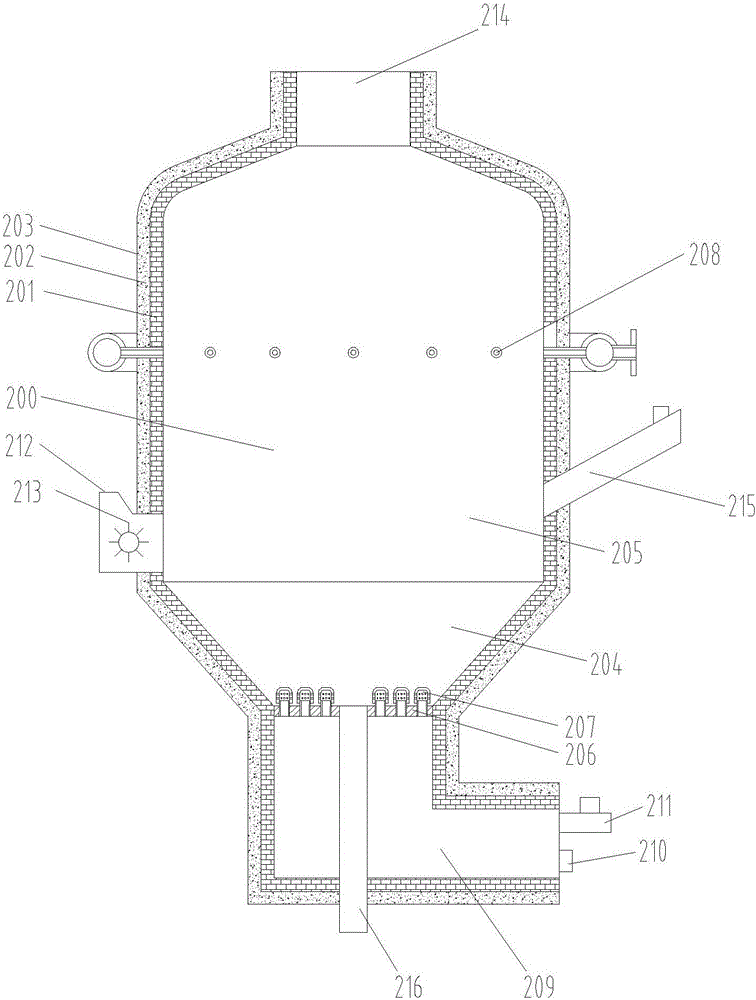

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

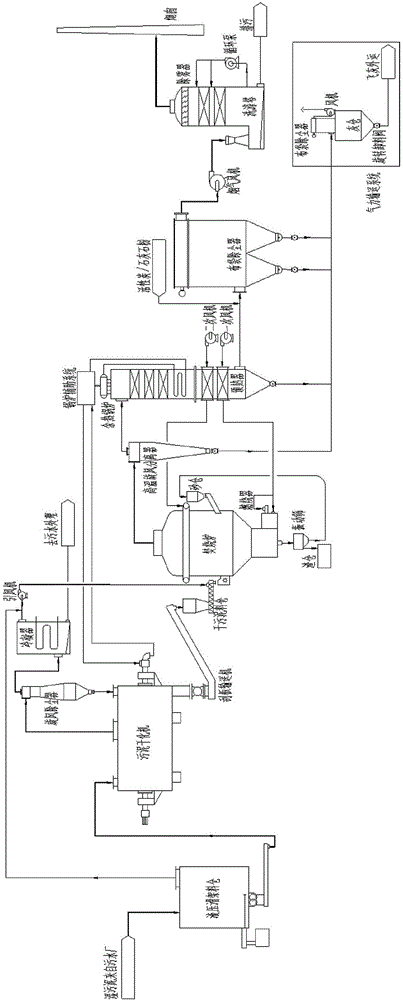

[0028] refer to Figure 1-3 , a sludge drying incineration disposal method, comprising the following:

[0029] The water treatment sludge from the sewage treatment plant is preliminarily dehydrated by pressure filtration, centrifugation, etc. After the water content is generally below 80%, it is transported to the special sludge silo with hydraulic slides, and the hydraulic slides break the sludge , continuously discharged from the bottom of the silo in a spiral, and then pumped to the horizontal sludge dryer through the sludge pump;

[0030] After sludge incineration, the high-temperature flue gas uses the steam produced by the waste heat boiler as the heat source ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com