Complete steam low-temperature thermally hardening, tempering and drying device and method for sludge

A complete set of treatment and low-temperature heating technology, which is applied in the field of solid waste and solid waste treatment, can solve the problems of high water content in sludge, high operating cost, and large heat consumption, and achieve low operating cost, high safety, and reduced The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

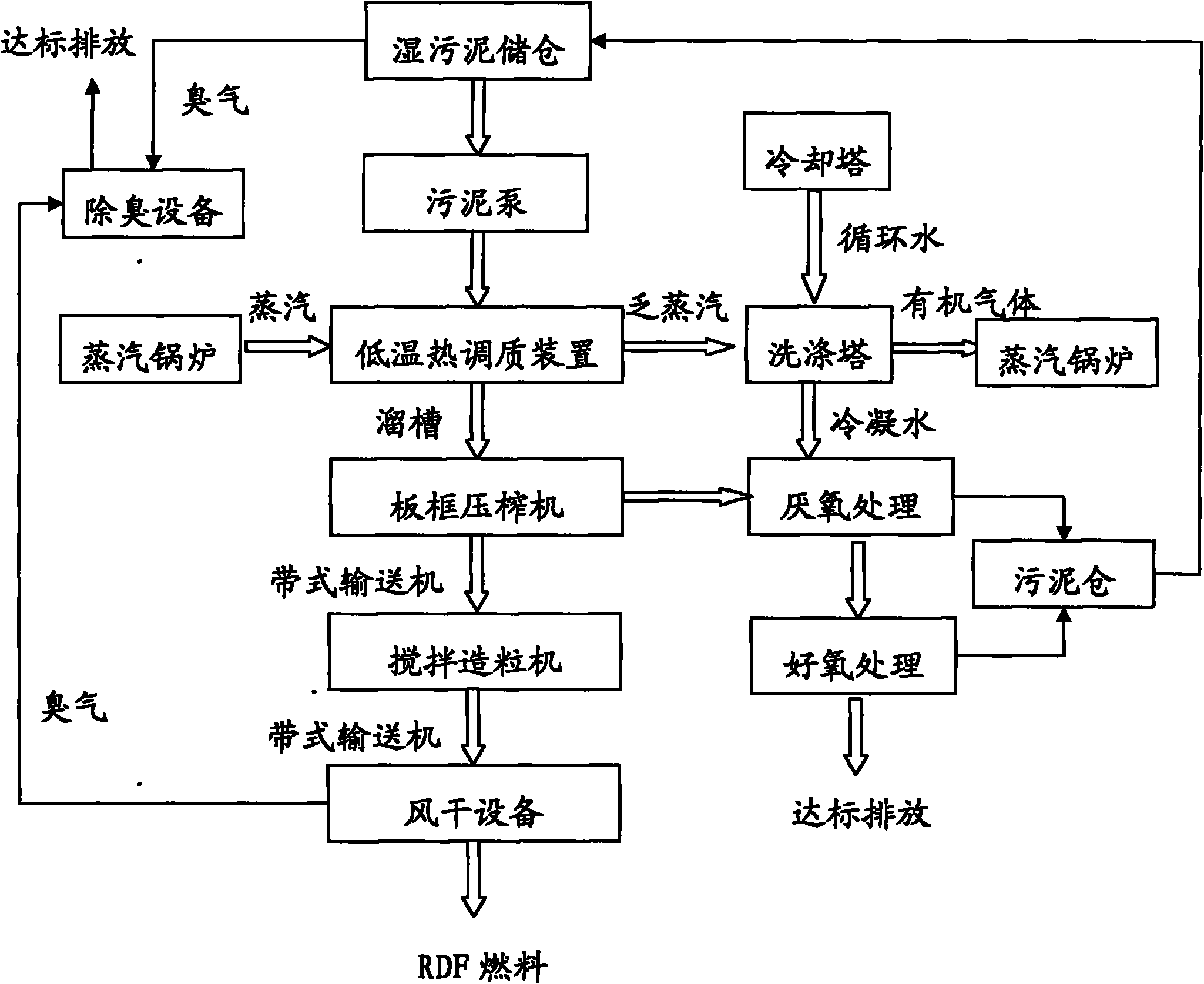

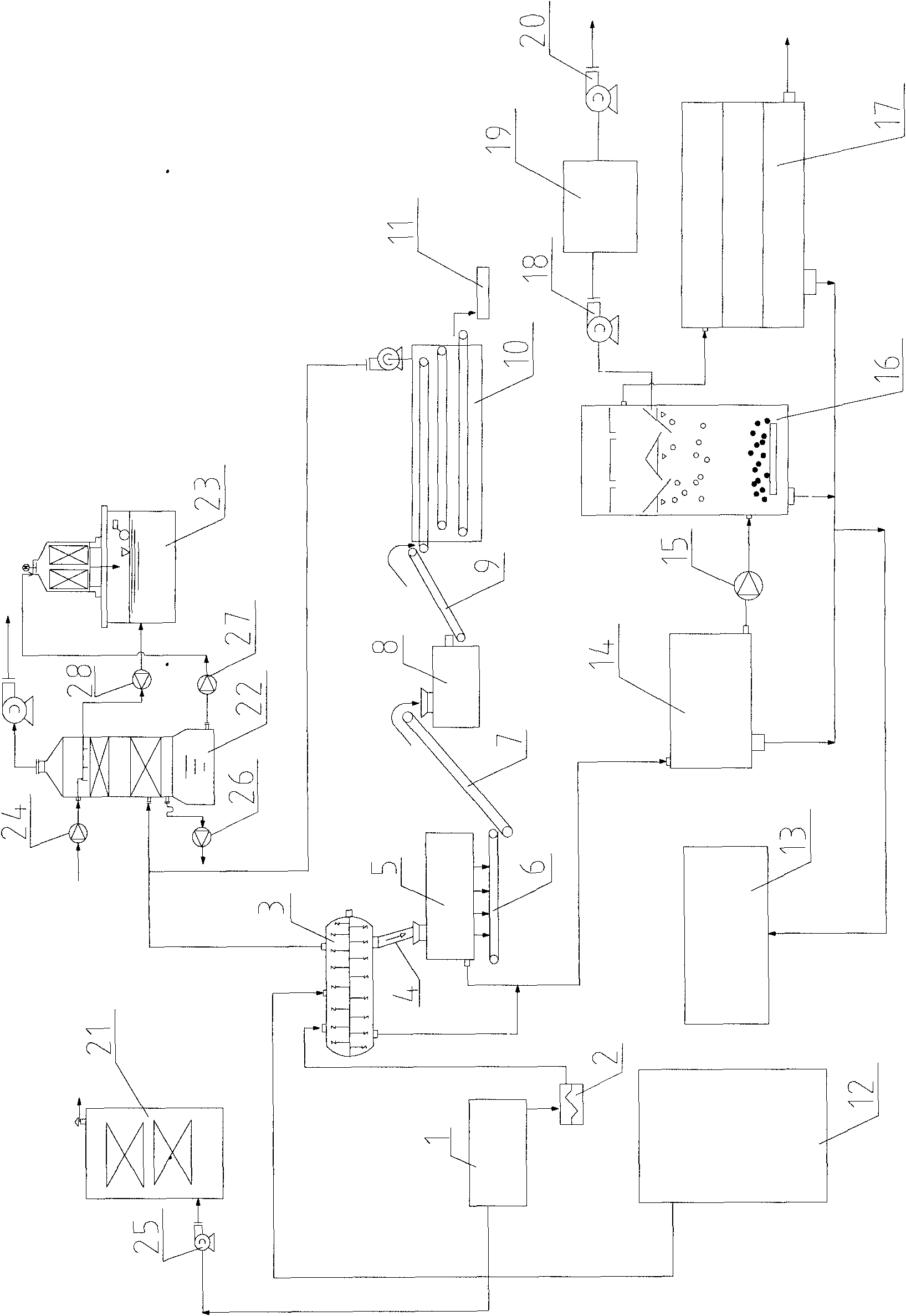

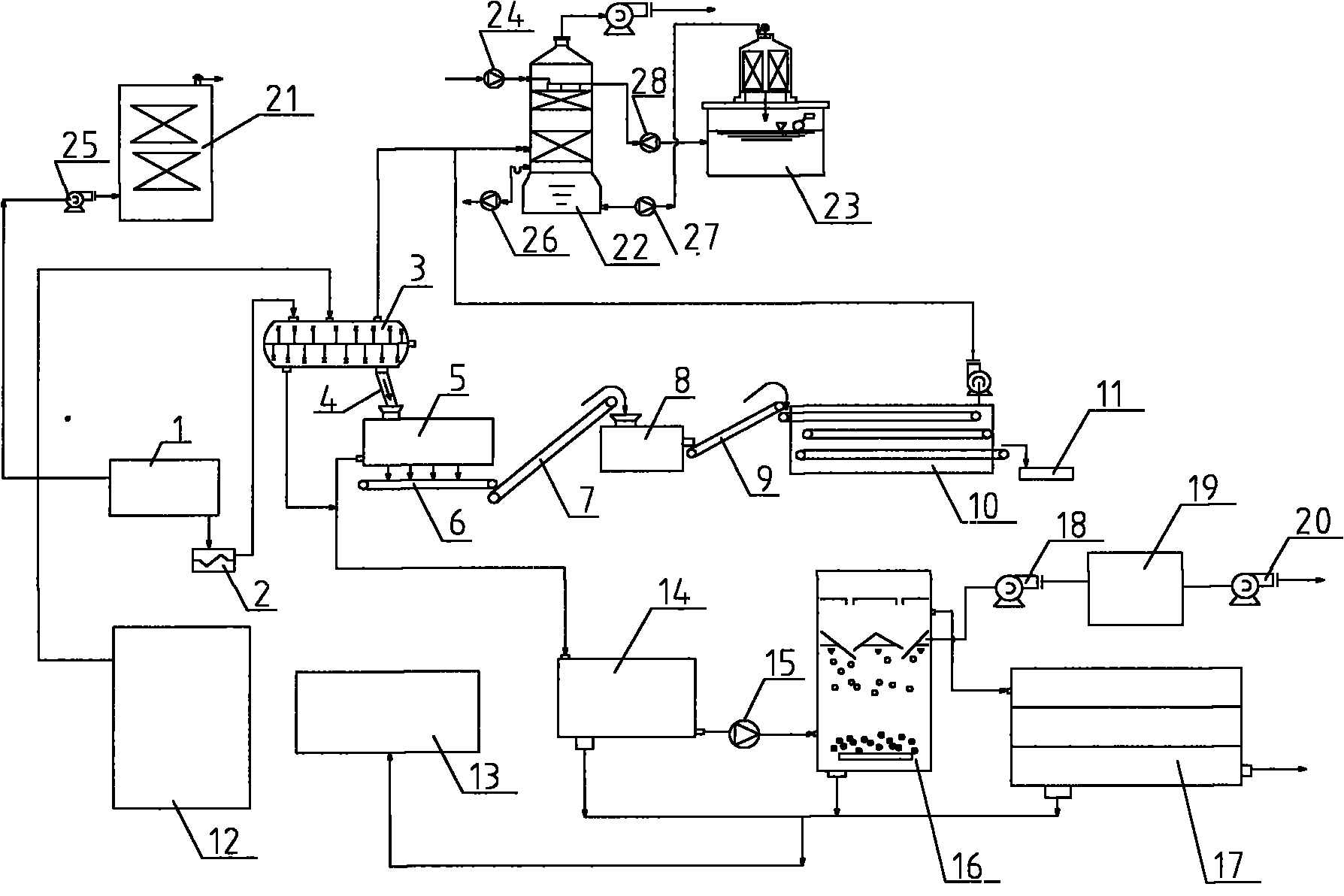

Embodiment 1

[0049] A complete treatment method of steam low-temperature thermal conditioning and drying of sludge is aimed at a sewage treatment plant with a scale of 100,000 tons per day, and the daily output of sludge with a moisture content of 80% is about 50 tons. Through the processing of this complete system, two 5m 3 The steam pyrolysis reactor, the sludge with a moisture content of about 80% is treated and dried to about 20%, and then made into RDF fuel for reuse.

[0050] The sludge with a moisture content of 80% is dumped into the wet sludge storage bin by a sludge transport vehicle. The wet sludge storage silo is located at the entrance of the drying workshop. The upper part of the silo is a half-closed and half-open device. After dumping, the silo is automatically closed. The sludge conveying pump is connected to the bottom of the wet sludge storage bin, and the feeder of the wet sludge storage bin supplies the sludge to the sludge pump, and the sludge pump continuously and u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com