Magnetic separation method and apparatus for mine water underground treatment

A magnetic separation and mine water technology, applied in mining wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of long treatment cycle, high treatment cost and high freight cost, and achieve reduction Effects of operating costs, accelerating precipitation, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

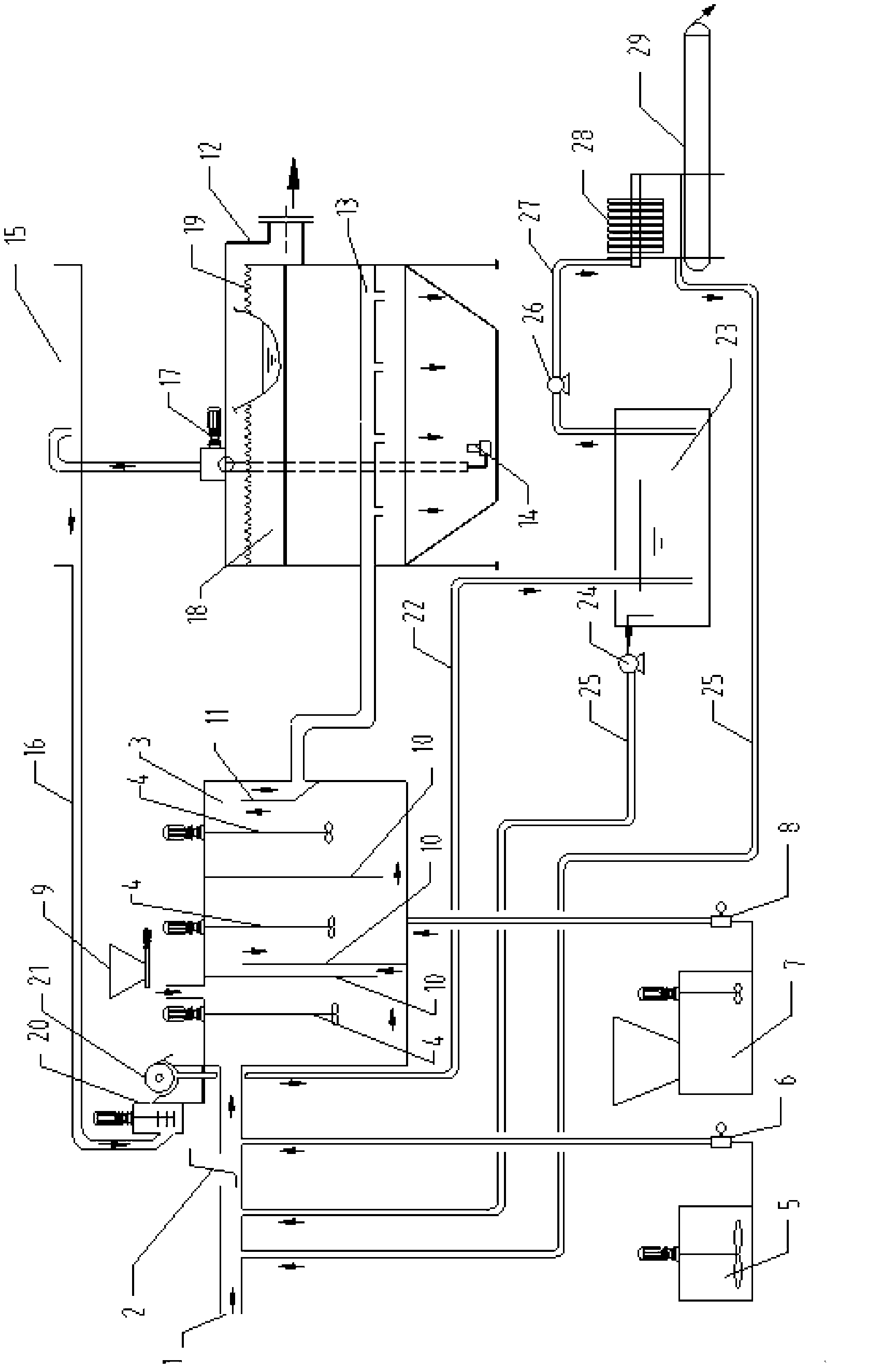

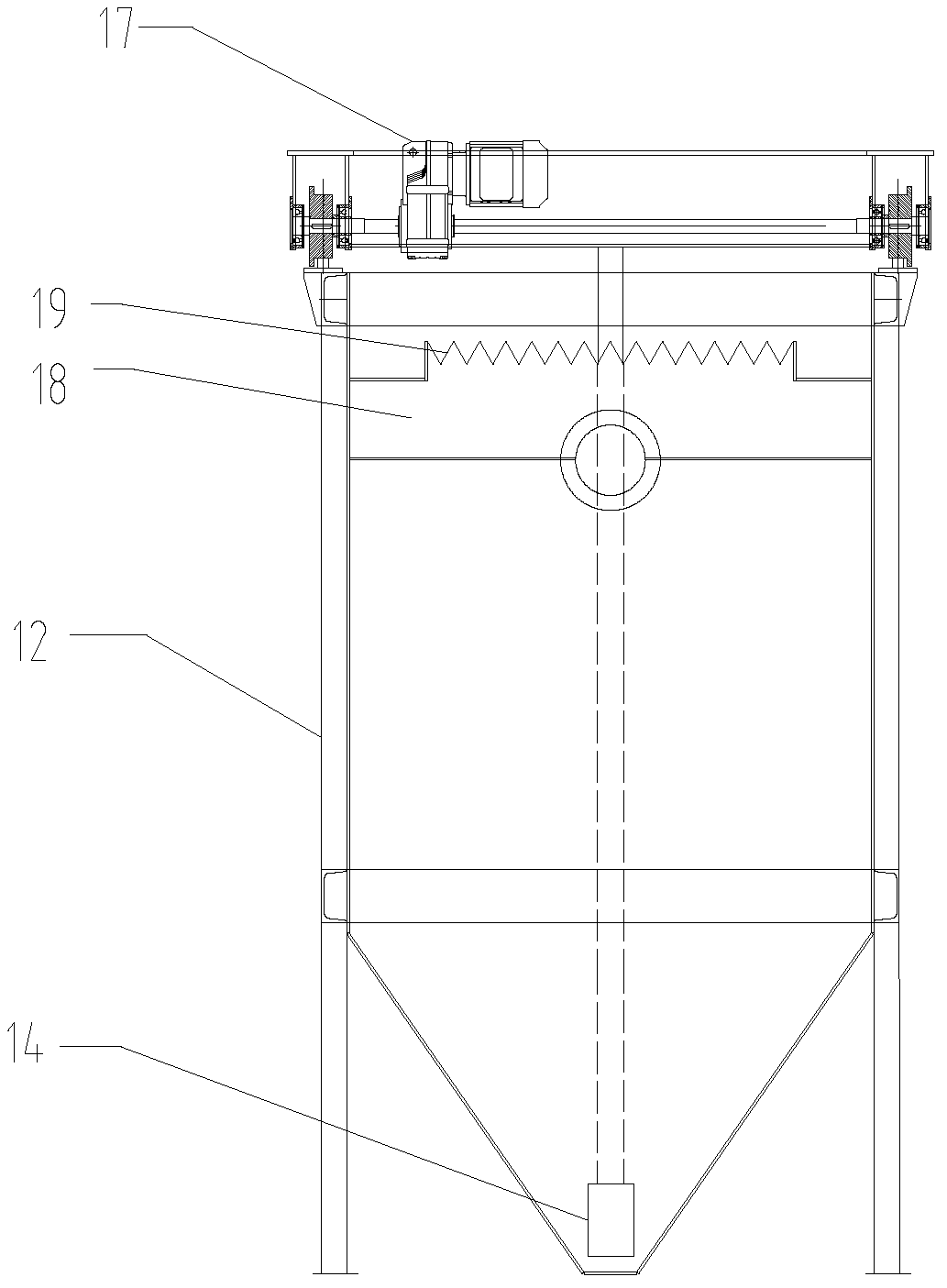

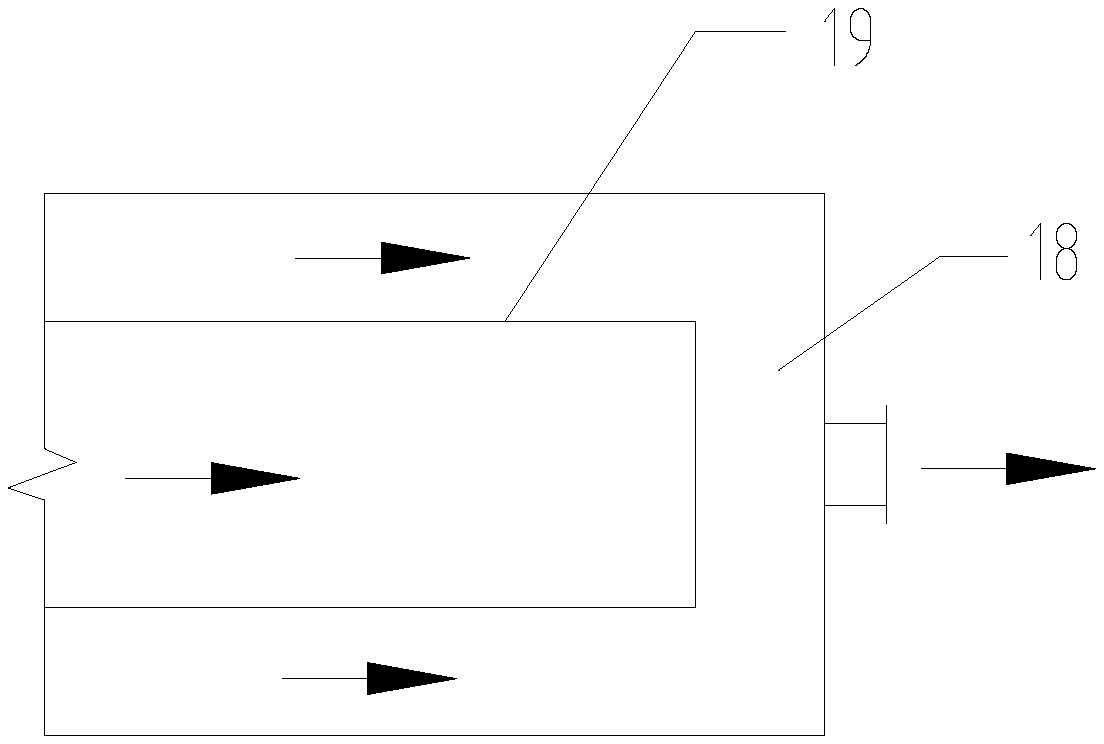

[0039] Such as figure 1 As shown, the magnetic separation device suitable for the underground treatment of mine water given in this embodiment includes a pretreatment mechanism, a magnetic flocculation mechanism, a magnetic precipitation mechanism, a magnetic separation mechanism and a sludge treatment mechanism connected in sequence.

[0040] Wherein the pretreatment mechanism is a grid 2, installed in the water inlet 1 of the device, to remove large particles such as sand, wood chips and floating objects, and regularly transported away after being collected.

[0041] The magnetic flocculation mechanism is composed of a flocculation tank 3, an agitator 4, a coagulant preparation storage tank 5, a coagulant metering pump 6, a coagulant aid preparation storage tank 7, a coagulant aid metering pump 8 and a magnetic seed quantitative dosing machine 9 . The flocculation tank 1 in this embodiment has three stages, which are separated by three partitions 10. Each stage of the flocc...

Embodiment 2

[0046] First remove the large particles of impurities and floating matter in the mine water that is directly transported from the mine through ditches or pipelines, and then according to the mine water test, if the suspended matter content in the mine water is 100-500mg / L, the COD is 30-60mg / L , according to the volume flow rate of mine water according to 500g / m 3 and 20g / m 3 Add ferric oxide and basic aluminum chloride, and stir for 1.5 minutes at a speed of 220 rpm, wherein the density of ferric oxide is 4.0 g / cm 3 , the particle size is 44μm; then the volume flow rate of mine water is 0.5g / m 3 Add anionic polyacrylamide coagulant, and stir for 1.5 minutes at a rotating speed of 30 rpm, and then stir for 4 minutes at a rotating speed of 10 rpm; stop adding magnetic seeds when the magnetic seeds reach equilibrium. 24 hours according to the volume flow of mine water according to 1-2g / m 3 Replenish once again; after the water treated by magnetic flocculation is transported t...

Embodiment 3

[0049] First remove the large particles of impurities and floating matter in the mine water directly transported through ditches or pipelines, and then according to the test of the mine water, if the suspended matter in the mine water is 500-1000mg / L and the COD is 60-80mg / L, Take the volume flow rate of mine water as 1000g / m 3 and 30g / m 3 Add ferric oxide and basic aluminum chloride, and stir for 2 minutes at a speed of 200 rpm, wherein the density of ferric oxide is 4.5g / cm 3 , the particle size is 150μm; then the volume flow rate of mine water is 1.0 g / m 3 Add cationic polyacrylamide coagulant, and stir for 2 minutes at a speed of 20 rpm, and then stir for 3 minutes at a speed of 20 rpm; stop adding magnetic seeds when the magnetic seeds reach equilibrium. 24 hours according to the volume flow of mine water according to 1-2g / m 3 Replenish once again; after the water treated by magnetic flocculation is transported to the sedimentation tank and relies on the self-weight of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com