Manufacture method for polarization maintaining fiber and polarization maintaining fiber

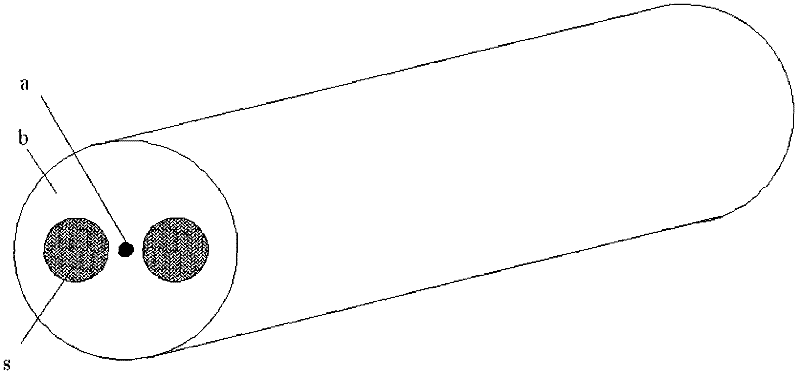

A polarization-maintaining optical fiber and manufacturing method technology, which is applied to polarization optical fibers, cladding optical fibers, and manufacturing tools, etc., can solve the adverse effects of polarization-maintaining optical fibers on the strength and optical performance, the difficulty of satisfying the small force of the drill bit, and the roughness of the inner surface of the processing hole. Advanced problems, to achieve good optical performance and reliability, low attenuation, good symmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

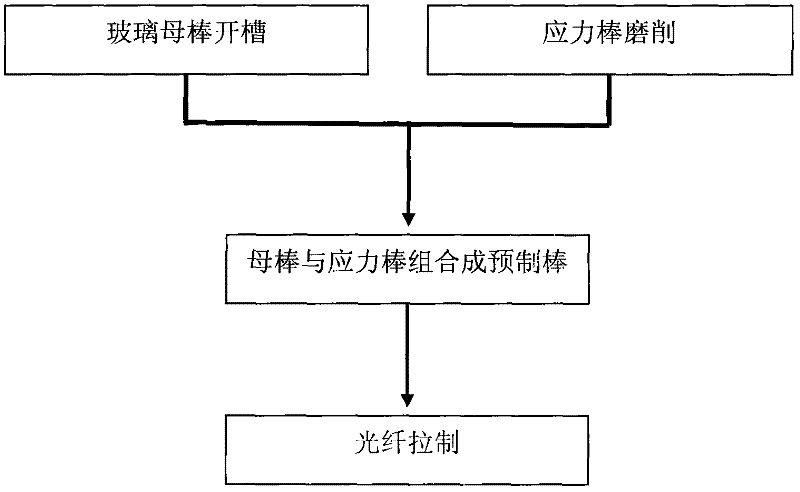

Method used

Image

Examples

Embodiment 1

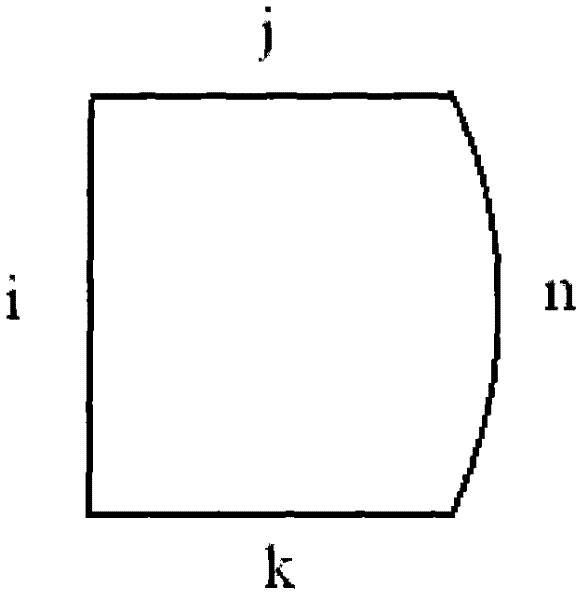

[0038] Such as Figure 2 to Figure 5 As shown, the glass mother bar e is processed into a cylinder, and its cross-section includes three right-angled sides i, j, k and an arc side n, wherein the right-angled sides j and k are parallel to each other, and the length is 15.10mm, and the right-angled side i is connected to one end of right-angled sides j and k respectively, and the length is 16.80mm. The arc side n is complementary to the side line of the cross-section of the glass mother rod e, and the radius of curvature of the arc side n is 21.60 mm. The core layer diameter is 3.79mm, the cladding diameter is 43.20mm quartz glass master rod e is processed from the side surface inwards two slots g opposite to each other and of the same shape, the size of the slot g matches the size of the stress rod s , the fit error is 0.12 mm, and the centerlines of the two slots g and the axis of the mother rod e are located on the same plane. As mentioned above, the center C2 of the cross-...

Embodiment 2

[0044] Such as Figure 2 to Figure 5 As shown, the glass mother rod e is processed into a cylinder, and its cross-section includes three right-angled sides i, j, k and one arc side n, wherein the right-angled sides j and k are parallel to each other, and the length is 17.62mm, and the right-angled side i is connected to one end of right-angled sides j and k respectively, and the length is 19.60mm. The arc side n is complementary to the side line of the cross-section of the glass mother rod e, and the radius of curvature of the arc side n is 25.20mm. The core layer diameter is 4.42mm, the cladding diameter is 50.40mm quartz glass mother rod e is machined from the side surface inwards two slots g which are oppositely arranged and have the same shape, and the size of the slot g matches the size of the stress rod s , the matching error is 0.15 mm, and the centerlines of the two slots g and the axis of the mother bar e are located on the same plane. As mentioned above, the center...

Embodiment 3

[0050] Such as Figure 2 to Figure 5 As shown, the glass mother bar e is processed into a cylinder, and its cross section includes three right-angled sides i, j, k and one arc side n, wherein the right-angled sides j and k are parallel to each other, and the length is 16.36mm, and the right-angled side i is connected to one end of right-angled sides j and k respectively, and the length is 18.20mm. The arc side n is complementary to the side line of the cross-section of the glass mother rod e, and the radius of curvature of the arc side n is 23.40 mm. The core layer diameter is 4.10mm, the cladding diameter is 46.80mm quartz glass master rod e is processed from the side surface inwards two slots g that are oppositely arranged and have the same shape, and the size of the slot g matches the size of the stress rod s , the fit error is 0.12 mm, and the centerlines of the two slots g and the axis of the mother rod e are located on the same plane. As mentioned above, the center C2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com