Microneedle array device and its fabrication method

a technology of microneedle array and fabrication method, which is applied in the field of microneedle array structure, can solve the problems of high cost, low yield rate, and complicated fabrication process of si substrate, and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0033]FIGS. 7A-7J shows the fabrication method of the present invention. First, a substrate is provided, which including a plurality of concave areas on the surface. According to the present invention, there are several techniques for forming a plurality of concave areas, including etching, X-ray photo-etching, ultra-violet etching, ion beam etching and excimer laser micromaching. The present embodiment uses an anisotropic wet etching for explanation.

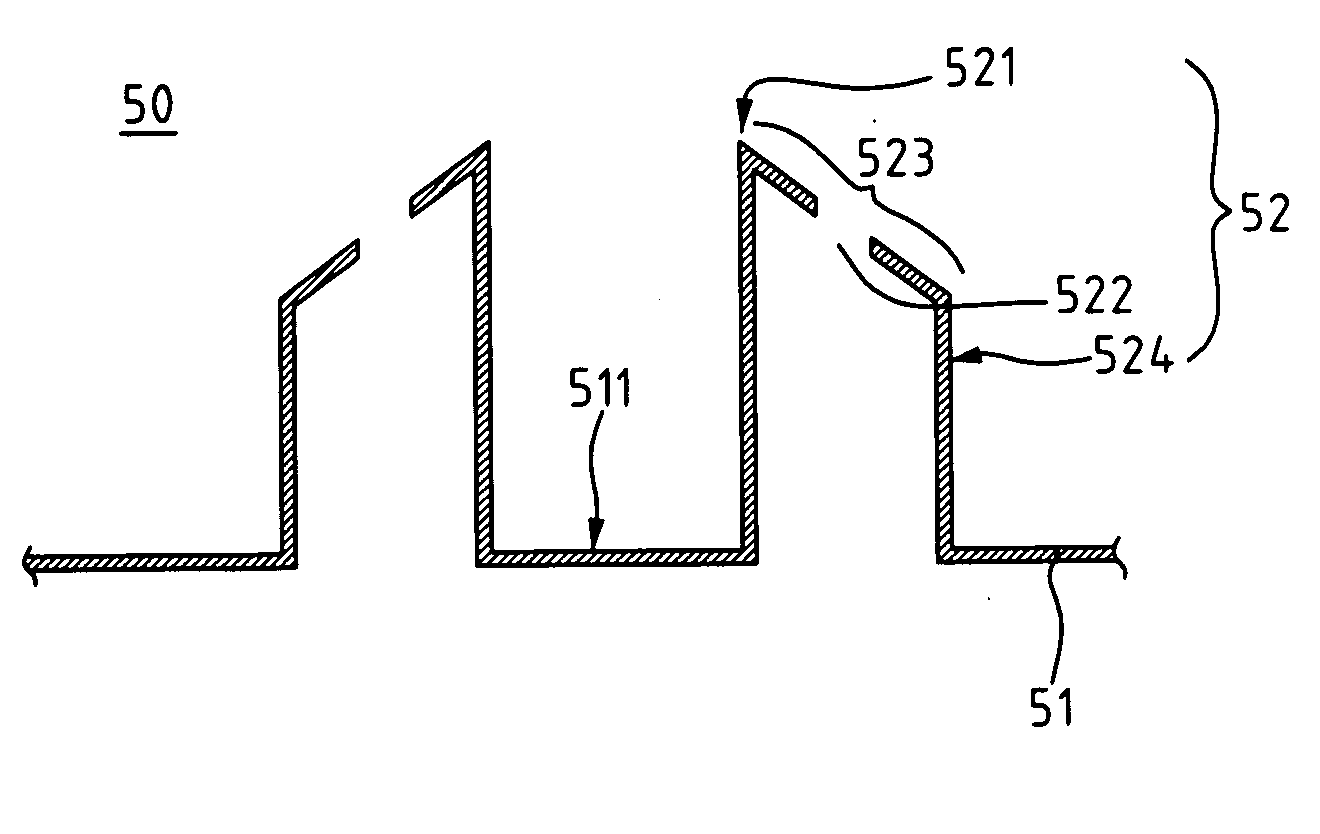

[0034] As shown in FIG. 7A, a single crystal silicon with a grainorientation [1,0,0] is used as a substrate 700, and a protective layer 702 is deposited on the surface. Protective layer 702 can be made of Si3N4. The wet etching areas 705 are defined, as shown in FIG. 7B, followed by wet etching. The solution commonly used in silicon anisotropic wet etching includes potassium hydroxide (KOH) and Tetra-methyl-ammonium hydroxide (TMAH). After etching the silicon, a plurality of concave areas 710 are formed. Each concave area 710 has two sl...

second embodiment

[0045]FIGS. 11A-11K show the fabrication method of the present invention.

[0046] The fabrication method of the second embodiment is similar to that of first embodiment. The only difference is in the exposure and development step. Because the second embodiment has a reservoir layer 91 in the structure, the second embodiment requires an additional exposure than the first embodiment. During the second exposure, a corresponding patterned mask 750a is used to define reservoir layer 91 and the shape of reservoir units 93 within. By adjusting the exposure dosage to control the depth “a” of the reservoir layer, the result of this step is to obtain a polymer hollow microneedle array mold 160. The remaining steps of the fabrication are identical to those in FIG. 7A-7J.

third embodiment

[0047]FIGS. 12A-12L show the fabrication method of the present invention.

[0048] The fabrication method of the third embodiment is also similar to that of first embodiment The only difference is still in the exposure and development step. Similarly, because the third embodiment has two more reservoir layers 101 in the structure, the third embodiment requires two additional exposures than the first embodiment. During the second and third exposures, a corresponding patterned mask 750a, 750b is used to define, respectively, each reservoir layer 101 and the shape of reservoir units 103 within. By adjusting the exposure dosage to control the depths “a” and “b” of the reservoir layers, the result of this step is to obtain a polymer hollow microneedle array mold 260. Therefore, according to the present invention, the first exposure is to form the shape and the structure of the microneedles, and the second and subsequent exposures are for forming the shape and the structure of the reservoir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com