Broadband high-sensitivity resonant piezoelectric MEMS microphone

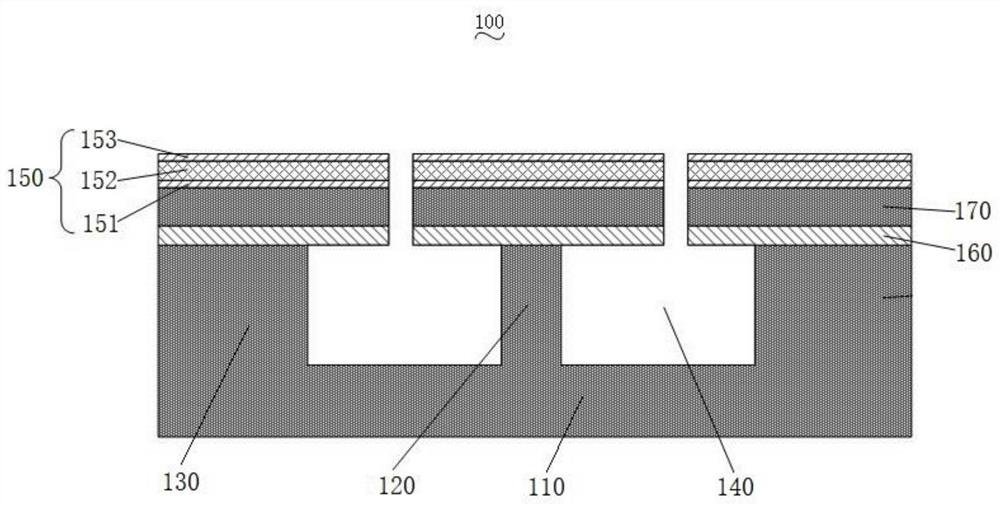

A high-sensitivity, resonant technology, applied in piezoelectric/electrostrictive transducer microphones, planar diaphragms, electrical components, etc., can solve problems such as low sensitivity and achieve high-sensitivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

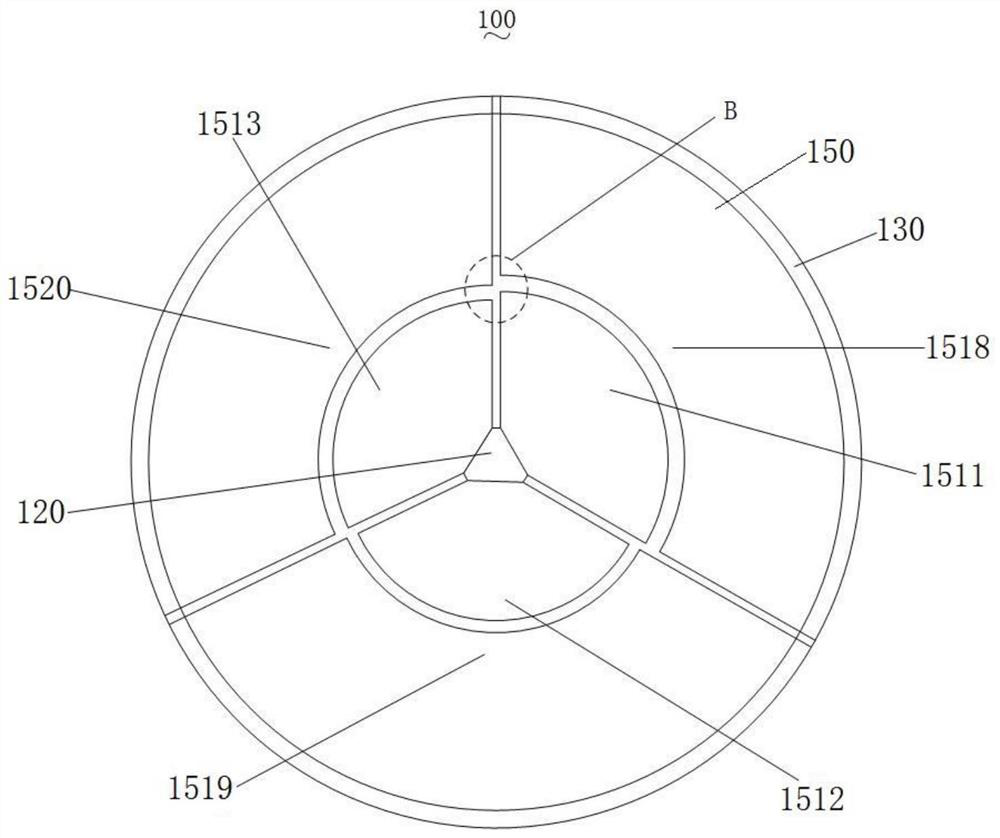

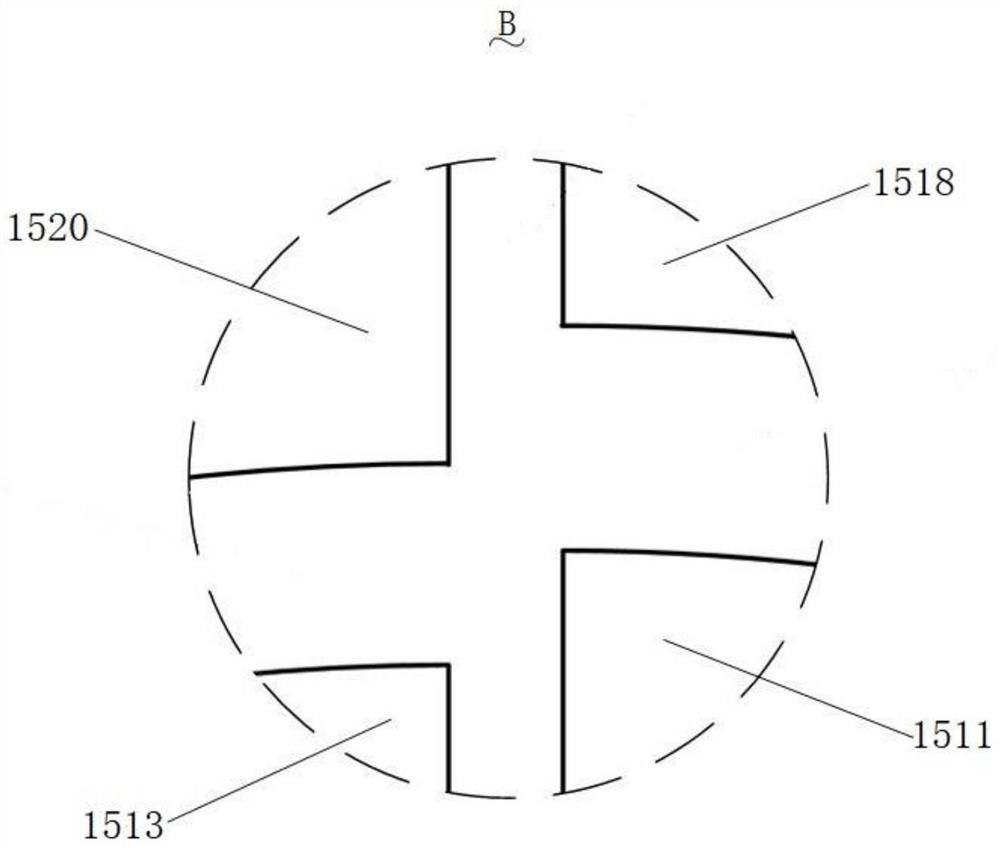

[0042] Embodiment one, with reference to figure 2 with image 3 As shown, the outer peripheral support part 130 has a ring-shaped structure, and three fan-shaped diaphragms 150 of different sizes are installed on the central support part 120, which are the first central diaphragm 1511, the second central diaphragm 1512 and the second central diaphragm 150 respectively. Three central diaphragms 1513, three fan-shaped diaphragms 150 of different sizes are installed on the peripheral support part 130, which are respectively the first peripheral diaphragm 1518, the second peripheral diaphragm 1519 and the third peripheral diaphragm 1520, one The central diaphragm, the second central diaphragm 1512 and the third central diaphragm 1513 present a stepped arrangement, the first peripheral diaphragm 1518, the second peripheral diaphragm 1519 and the third peripheral diaphragm 1520 present a stepped arrangement, the second The first central diaphragm 1511 , the second central diaphrag...

Embodiment 2

[0045] Embodiment two, refer to Figure 4 As shown, the outer peripheral support part 130 is a square ring structure, and four trapezoidal diaphragms 150 of the same size are installed on the central support part 120, which are respectively the fourth central diaphragm 1514, the fifth central diaphragm 1515, and the sixth diaphragm 150. The central diaphragm 1516 and the seventh central diaphragm 1517, four trapezoidal diaphragms 150 of the same size are installed on the peripheral support part 130, which are respectively the fourth peripheral diaphragm 1521, the fifth peripheral diaphragm 1522, and the sixth peripheral diaphragm. diaphragm 1523 and a seventh peripheral diaphragm 1524 . The fourth central diaphragm 1514, the fifth central diaphragm 1515, the sixth central diaphragm 1516 and the seventh central diaphragm 1517 have the same shape and size, the fourth peripheral diaphragm 1521, the fifth peripheral diaphragm 1522, the sixth peripheral diaphragm The diaphragm 152...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com