Rapid laser preparing method for composite with graphene loaded with spherical inorganic fullerene molybdenum disulfide

A technology of fullerene molybdenum disulfide and molybdenum disulfide, applied in graphene, molybdenum sulfide, petroleum industry, etc., can solve the problems of cumbersome preparation process and harsh conditions, achieve high product purity, fast reaction, and avoid harsh conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Weigh 0.24 g of sodium molybdate (purity 99%) and 0.15 g of thioacetamide (purity 98%) into a beaker, add 50 mL of deionized water, stir magnetically until the powder is completely dissolved; then transfer the solution into the reaction Kettle, kept at 180°C for 24 hours; after cooling, centrifuged and washed 7 times with deionized water to obtain flake molybdenum disulfide suspension evenly dispersed in aqueous solution;

[0033] (2) 2.0 mL of graphene oxide solution (0.8 mg mL -1 ) was added to the above molybdenum disulfide suspension, and the concentration after mixing the two was 0.8 mg mL -1 , ultrasonic dispersion for 5 min;

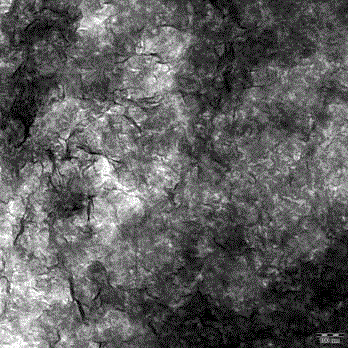

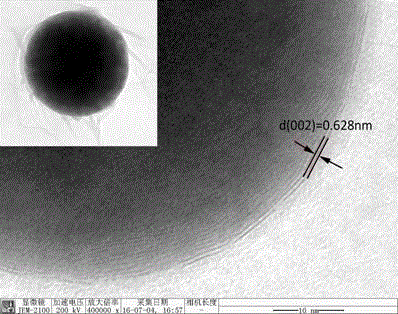

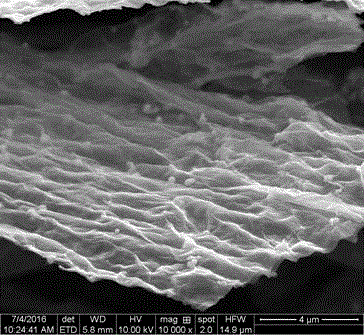

[0034] (3) Irradiate the mixed suspension prepared in the above step (2) with the krypton-fluorine laser beam (248 nm) focused by the mirror and the convex lens, and the laser energy density is 300 mJ pulse -1 cm -1 , the frequency is 15 Hz, and the irradiation time is 20 min. During laser beam irradiation, a magnetic stirrer was u...

Embodiment 2

[0038] (1) Weigh 0.24 g sodium molybdate (99% purity), 0.19 g thioacetamide (98% purity) and 0.15 g silicotungstic acid (98% purity) into a beaker, add 50 mL deionized water, Stir magnetically until the powder is completely dissolved; then transfer the solution into a reaction kettle and keep it warm at 220°C for 10 h; after cooling, wash it with deionized water for 7 times to obtain a flake molybdenum disulfide suspension evenly dispersed in the aqueous solution;

[0039] (2) 2 mL of graphene oxide solution (0.8 mg mL -1 ) was added to the above molybdenum disulfide suspension, and the concentration after mixing the two was 5 mg mL -1 , ultrasonic dispersion for 15 min;

[0040] (3) The mixed suspension prepared in the above step (2) is irradiated with the krypton-fluorine laser beam (248 nm) focused by the mirror and the convex lens, and the laser energy density is 500 mJ pulse -1 cm -1 , the frequency is 10 Hz, and the irradiation time is 40 min. During laser beam irra...

Embodiment 3

[0043] (1) Weigh 0.24 g sodium molybdate (purity 99%), 0.21 g thioacetamide (purity 98%) and 0.15 g polyethylene glycol (purity 98%) into a beaker, add 50 mL deionized water , magnetically stirred until the powder was completely dissolved; then the solution was transferred into a reaction kettle and kept at 200°C for 16 h; after cooling, it was centrifugally washed with deionized water for 5 times to obtain a flaky molybdenum disulfide suspension uniformly dispersed in an aqueous solution ;

[0044] (2) 3 mL of graphene oxide solution (0.8 mg mL -1 ) was added to the above molybdenum disulfide suspension, and the concentration after mixing the two was 15 mg mL -1 , ultrasonic dispersion for 30 min;

[0045] (3) Irradiate the mixed suspension prepared in the above step (2) with the krypton-fluorine laser beam (248 nm) focused by the mirror and the convex lens, and the laser energy density is 700 mJ pulse -1 cm -1 , the frequency was 5 Hz, and the irradiation time was 60 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com