Multi-metal golf clubs

a golf club and multi-metal technology, applied in the field of golf clubs, can solve the problems of club head failure, golf club head delamination or corrosion, club head failure, etc., and achieve the effect of improving the performance of the club

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

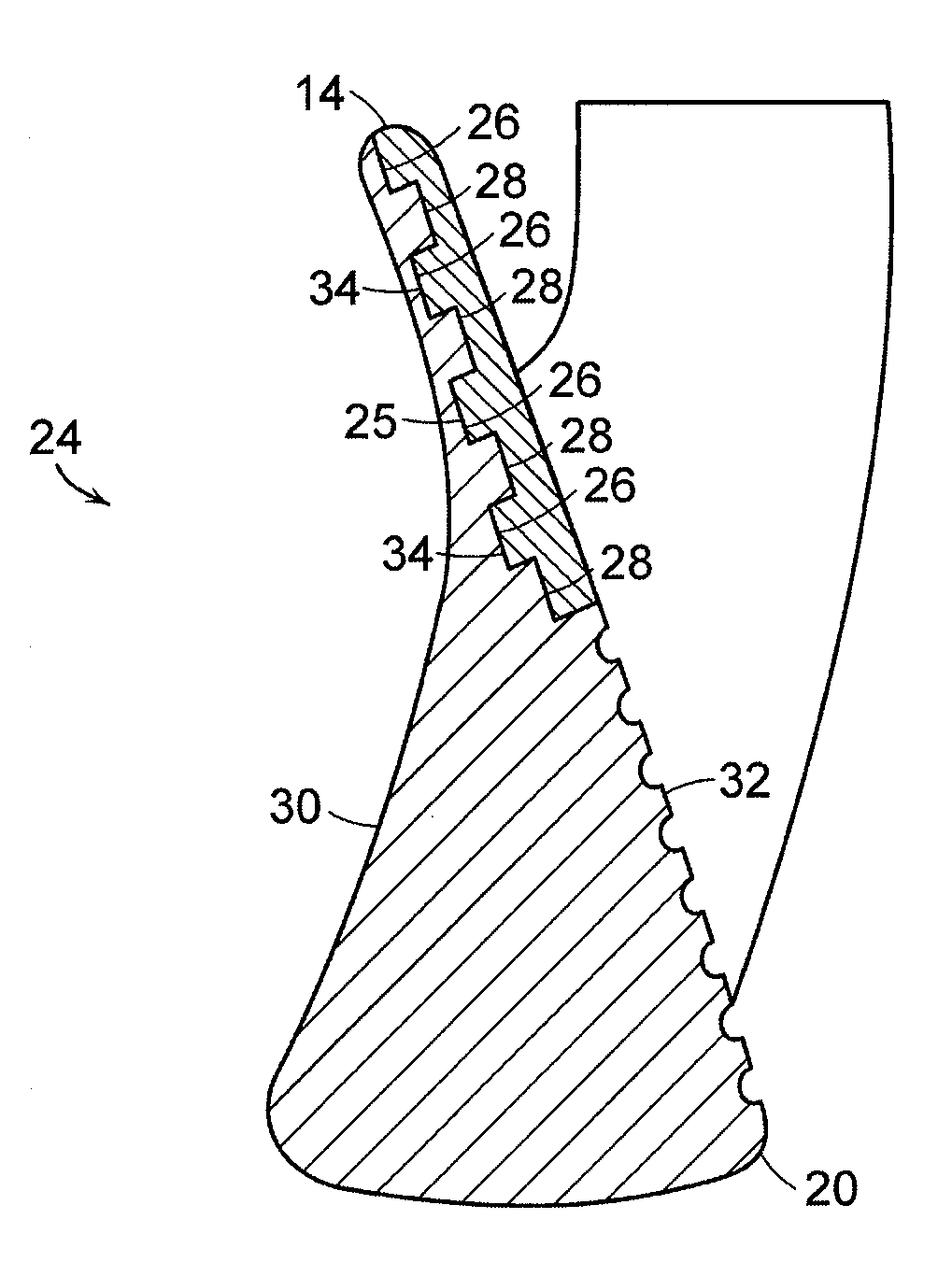

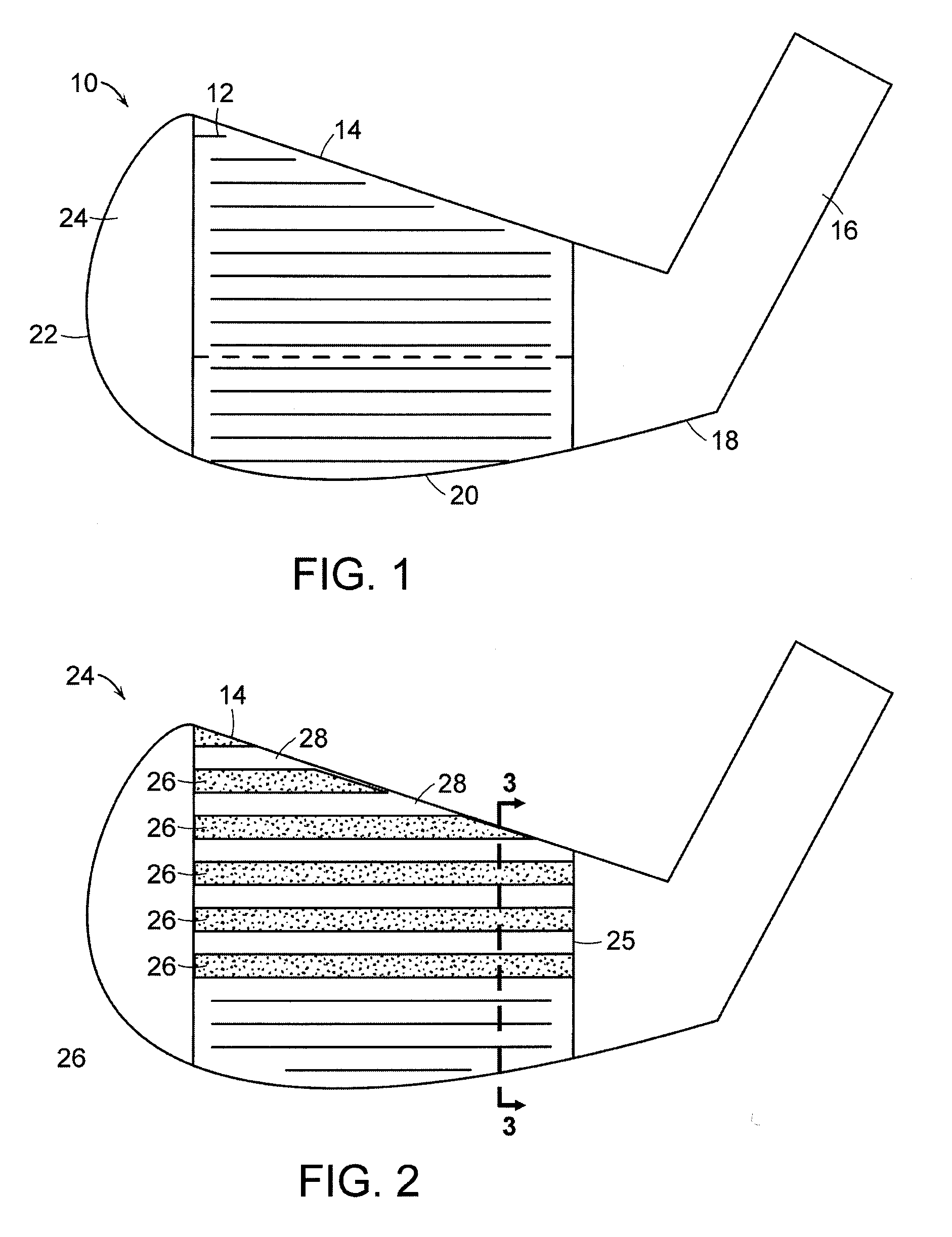

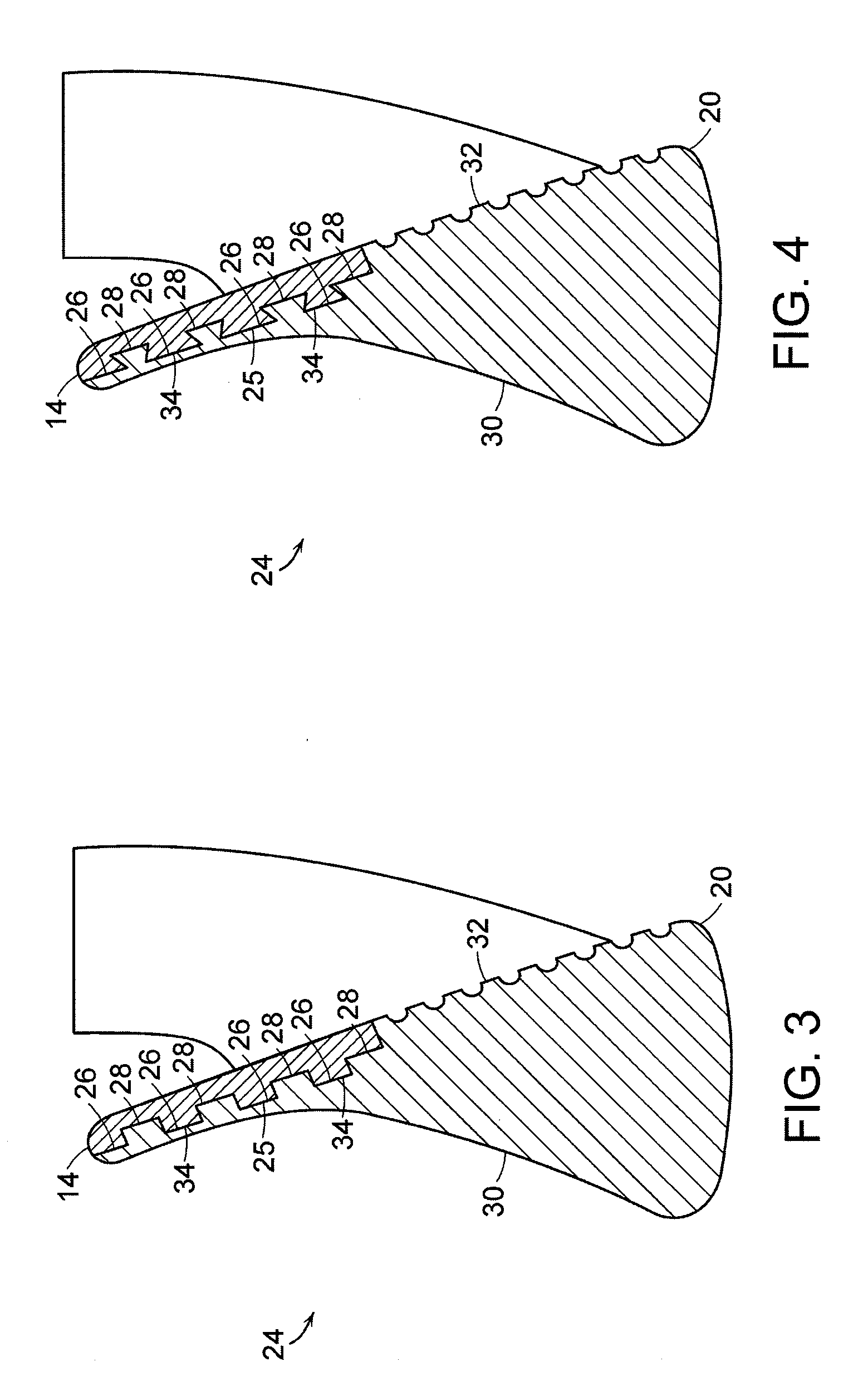

[0023]Referring now to the accompanying FIGS. 1-7, exemplary embodiments of the golf club head 10 in accordance with the present invention include face insert 12 and body portion 24, which is attached to hosel 16. Hosel 16 is adapted to receive a shaft (not shown). Club head 10 is preferably cast or forged from suitable material such as stainless steel, carbon steel, or titanium. In one embodiment, body portion 24 is a cast body portion. Body portion 24 includes crown or top line 14, toe 22, sole 20 and heel 18 that form the perimeter of body portion 24. Hosel 16 extends generally from heel 18 of body portion 24. In one embodiment, club head 10 is arranged as muscle-back iron-type club head that has a thicker bottom back portion. Body portion 24 also includes front 32 forming the hitting surface.

[0024]Improvement in the location of the center of gravity of golf club heads in accordance with the present invention is achieved through the use of a composite construction that utilizes v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com