Graphene-nano polytetrafluoroethylene composite filler as well as preparation method and application thereof

A polytetrafluoroethylene and composite filler technology is applied in the field of friction materials, which can solve the problems of lack of layered structure, inability to perform interlayer slippage, and inability to achieve lubricating effect, achieving a wide range of applications and a reliable and easy preparation method. The effect of improving the tribological performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

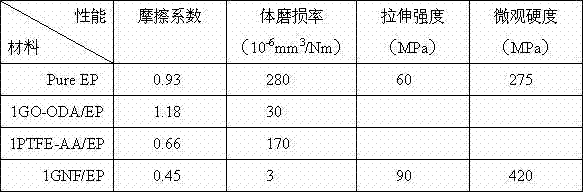

Image

Examples

Embodiment 1

[0029] At room temperature, 0.1 g of graphene oxide was dispersed in 300 g of N,N-dimethylformamide by ultrasound. After ultrasonic dispersion for 1 hour, 5 g of diphenyl ether diamine was added, and the reaction was stirred at 80° C. for 12 hours. The reacted dispersion liquid is vacuum filtered, washed and dried to obtain modified graphene. 1 gram of nano-polytetrafluoroethylene reacts with acrylic acid under irradiation to obtain modified nano-polytetrafluoroethylene. Take 0.09 g of modified graphene and 0.9 g of modified nano-polytetrafluoroethylene and ultrasonically disperse them in 300 g of N,N-dimethylformamide, add 1.12 g of 1-(3-dimethylaminopropyl)-3- Ethylcarbodiimide hydrochloride, 1.58 grams of 1-hydroxybenzotriazole and 10 milliliters of triethylamine were stirred and reacted at 40°C for 24 hours, filtered and washed, and vacuum-dried overnight at 70°C to obtain graphene-nanopolymer Tetrafluoroethylene composite filler.

Embodiment 2

[0031] Disperse 0.2 g of partially reduced graphene oxide in 500 g of N,N-dimethylformamide by ultrasonic at room temperature, after ultrasonic dispersion for 2 hours, add 10 g of diphenyl ether diamine, and stir for 18 hours at 80°C . The reacted dispersion liquid is vacuum filtered, washed and dried to obtain modified graphene. 2 grams of nano-polytetrafluoroethylene reacted with acrylic acid under irradiation to obtain modified nano-polytetrafluoroethylene. Take 0.09 g of modified graphene and 1.8 g of modified nano-polytetrafluoroethylene and ultrasonically disperse them in 300 g of N,N-dimethylformamide, add 1.56 g of 1-(3-dimethylaminopropyl)-3- Ethylcarbodiimide hydrochloride, 2.20 grams of 1-hydroxybenzotriazole and 15 milliliters of triethylamine were stirred and reacted at 40°C for 24 hours, filtered and washed, and vacuum-dried overnight at 70°C to obtain graphene-nanopolymer Tetrafluoroethylene composite filler.

Embodiment 3

[0033]0.1 g of partially reduced graphene oxide was dispersed in 300 g of N,N-dimethylformamide by ultrasonic at room temperature. After ultrasonic dispersion for 1 hour, 5 g of p-phenylenediamine was added, and the reaction was stirred at 70°C for 12 hours. The reacted dispersion liquid is vacuum filtered, washed and dried to obtain modified graphene. 1 gram of nano-polytetrafluoroethylene reacts with acrylic acid under irradiation to obtain modified nano-polytetrafluoroethylene. Take 0.09 g of modified graphene and 0.9 g of modified nano-polytetrafluoroethylene and ultrasonically disperse them in 300 g of N,N-dimethylformamide, add 1.12 g of 1-(3-dimethylaminopropyl)-3- Ethylcarbodiimide hydrochloride, 1.58 grams of 1-hydroxybenzotriazole and 10 milliliters of triethylamine were stirred and reacted at 30°C for 24 hours, filtered and washed, and vacuum-dried overnight at 60°C to obtain graphene-nanopolymer Tetrafluoroethylene composite filler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com