Deep hole static rock breaking method for underground coal mine

A rock-breaking and deep-hole technology, applied in the field of deep-hole static rock-breaking method, can solve the problems of difficult process control, vibration sensation, casualties, etc., and achieve the effect of mild rock breaking process, simple and convenient construction process, and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

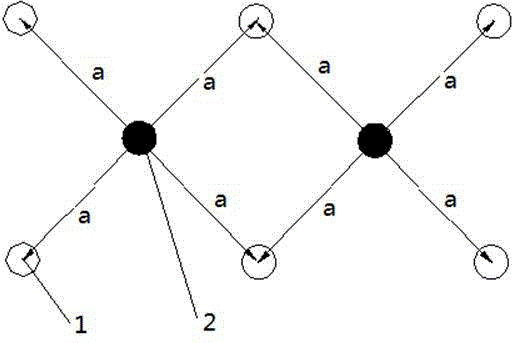

[0064] The gob-side entry retaining technology is composed of the support in the entry and the support beside the entry. Most of the weight of the collapsed rock blocks on the basic roof and its upper part is transferred to the solid coal side and the side support, making the coal side In order to maintain the stability of gob-side retaining, it is necessary to strengthen the anchor support of the solid coal side and increase the width and strength of the support body beside the roadway, which makes the support cost high and the remaining time during the mining period. The lane has a large amount of deformation and is difficult to maintain. In the return airway of the upper section of the working face next to the gob-side entry of the gob-side retaining entry, the application of the present invention is used for deep hole static rock breaking in coal mines to crush and cut off the top plate of the entryway to relieve pressure, so that the support body and The load borne by the...

Embodiment 2

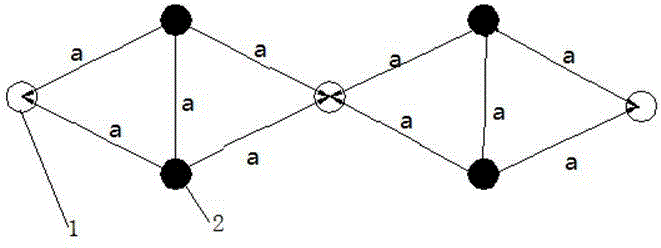

[0074] In the process of underground mining of hard roof coal seams, the overhanging area of the initial mining roof on the working face is relatively large, which restricts the smooth progress of mining. The deep hole static rock breaking method used in underground coal mines of the present invention is used to implement deep hole static rock breaking on the inner roof of the cut hole. The rock is broken to cause cracks and fractures in the basic top rock layer in the cut hole, and the working face collapses in time under the action of gravity after the start of mining, reducing the initial pressing step of the roof of the working face to ensure the normal progress of the initial mining work. The rock method is carried out in the following steps:

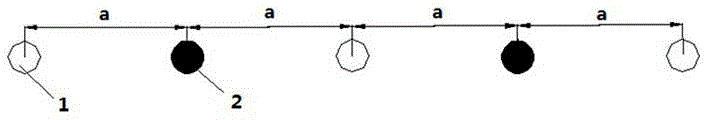

[0075] (1) Experimentally determine the Platts hardness coefficient f=4 of the rock mass of the cut-hole roof of a mine, and choose a straight-line hole layout structure to arrange a row of straight-line drill holes on the roof of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com