Self-adapting hybrid bit

A hybrid drill bit, self-adaptive technology, applied in drill bits, drilling equipment, earth-moving drilling and other directions, can solve the problems of affecting the rock-breaking effect of the drill bit and the inability to adjust the distribution of the roller cone pressure, so as to optimize the distribution of the rock-breaking amount, break The effect of fast rock speed and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

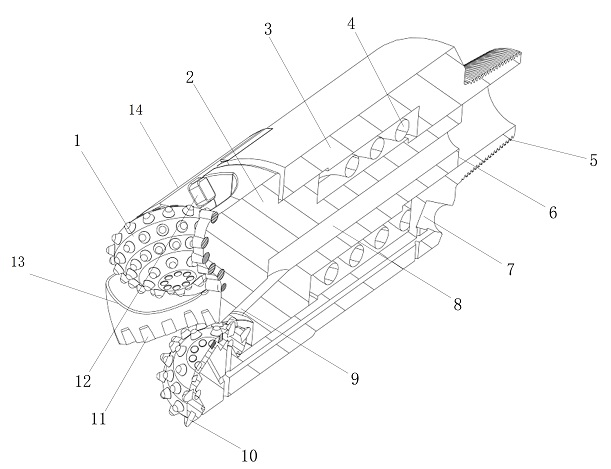

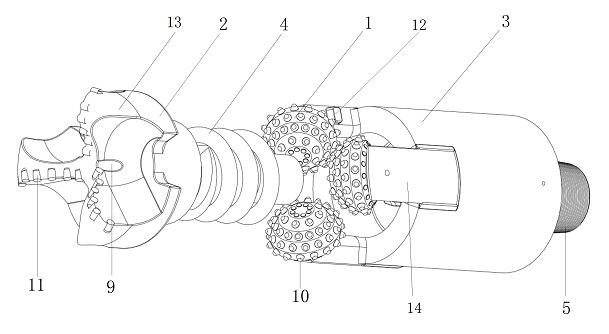

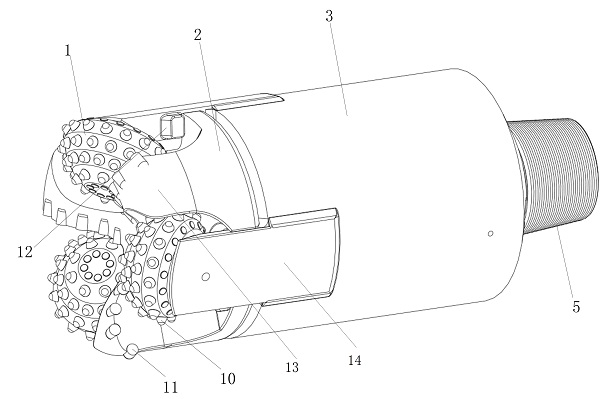

[0020] Such as Figures 1 to 3 As shown, a self-adaptive hybrid drill bit, the end of the drill body 3 is provided with a thread 5 connected to the drill pipe, and the front end is provided with a three-claw type palm 14, and the palm 14 is connected with the cone 1 through a sliding bearing, and can be wound around it. Rotating on its own axis, teeth 10 are inlaid on the cones 1, and there are three blades 13 between the cones 1, and there are diamond composite sheets 11 on the blades 13. The number of cones 1 and blades 13 of the self-adaptive hybrid drill bit is not limited, preferably 2, 3 or 4, as long as the cones 1 and blades 13 are arranged alternately and evenly. Also on the drill bit body 3 is a pressure-balanced device 7 that provides lubricating oil for the bearings. It also includes a movable blade body 2 that is movable in the drill body 3 and can only move back and forth in the axial direction within a limited range. The movable blade body 2 can slide in the dr...

Embodiment 2

[0026] This embodiment is basically the same as Embodiment 1, the difference is that the elastic element is a disc spring.

Embodiment 3

[0028] This embodiment is basically the same as Embodiment 1, the difference is that the elastic element is a rubber spring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com