Resonant pulse vibrating drilling device

A technology of pulse vibration and drilling, which is applied in the direction of vibration drilling, vibration generating devices, and driving devices for drilling in boreholes, etc. It can solve the problems of limited drilling speed increase effect, short service life, wear and erosion in abrasive formations, and achieve Solve the effect of low rock breaking efficiency and improve rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

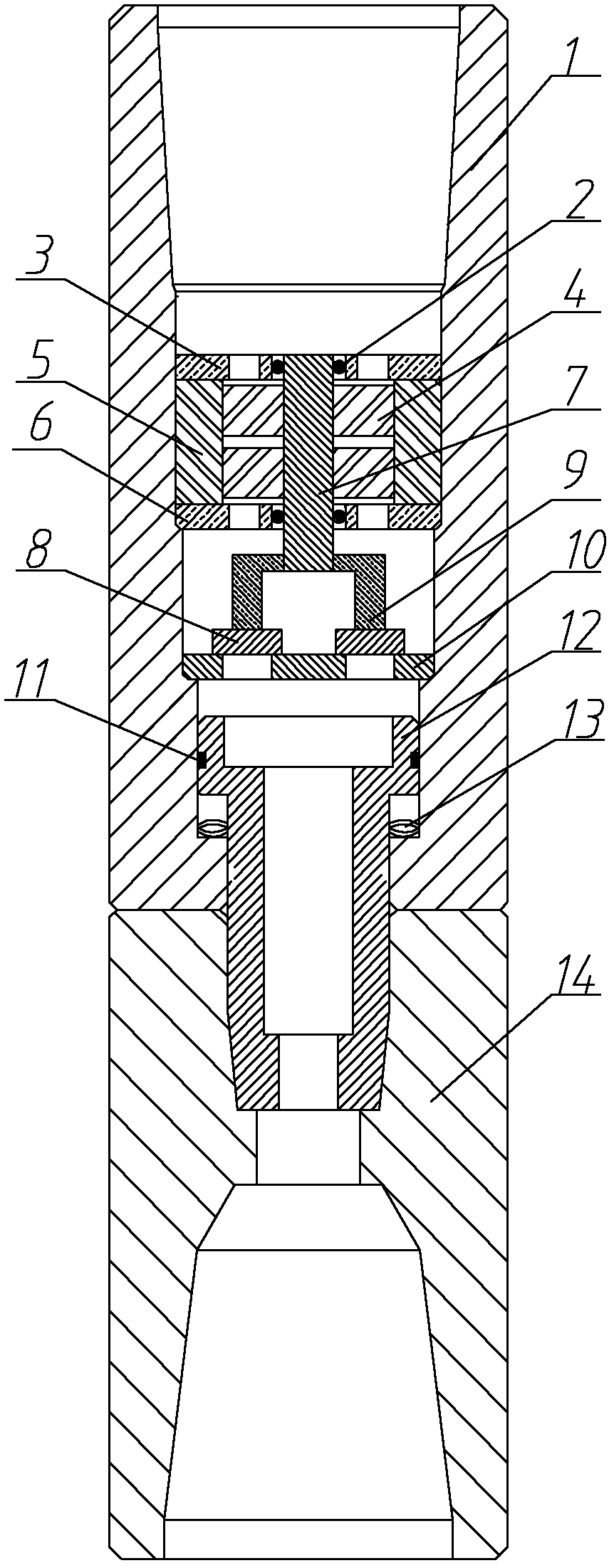

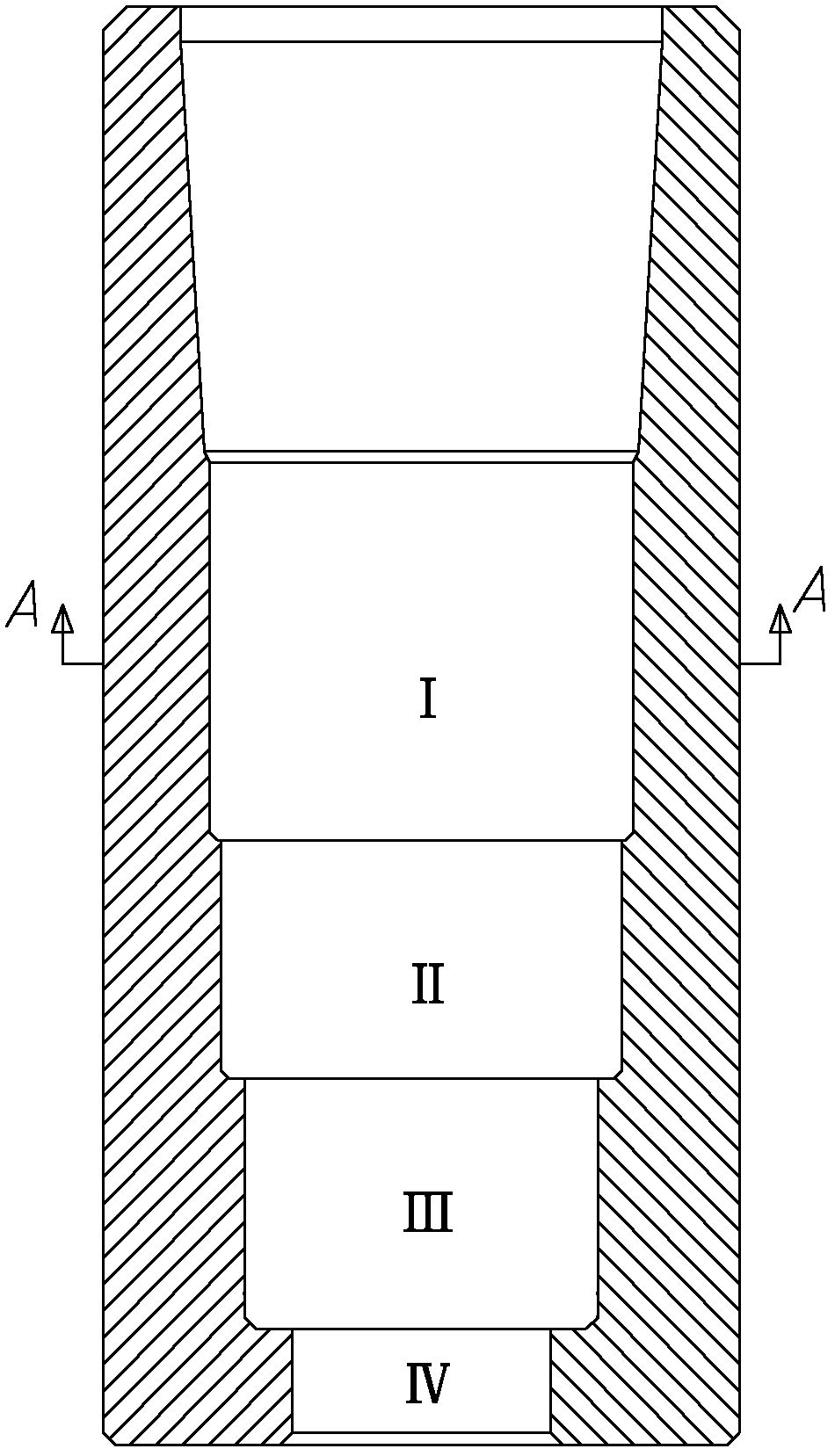

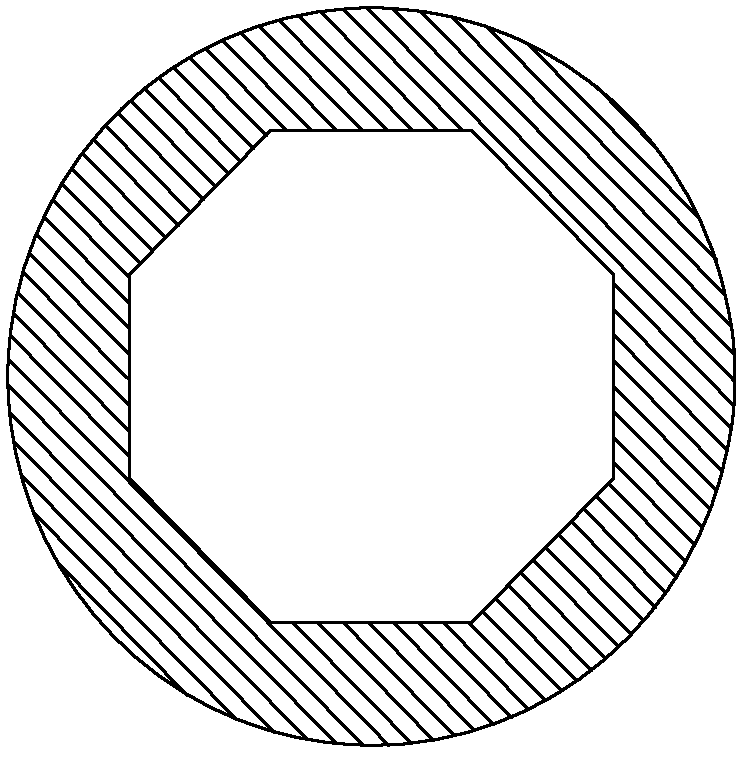

[0042] See attached figure 1, The resonant pulse vibration drilling device provided by the present invention is cylindrical in shape and includes an outer shell 1 and a turbine power system placed in the outer shell 1 , a pulse modulation system, a resonant pulse and reciprocating vibration system, and a lower joint 14 . The turbine power system is used to control the action of the pulse modulation system. The pulse modulation system is used to make the continuous flow of drilling fluid into a pulse jet with a certain period. The resonant pulse and reciprocating vibration system is used to amplify the pulse amplitude of the pulse jet so that Perform periodic up and down reciprocating vibrations. See attached figure 2 , there are stepped through holes with decreasing diameter or equivalent value in the outer shell 1, which are divided into through holes of stage I, through holes of stage II, through holes of stage III and through holes of stage IV, and the through holes of st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com