Substrate treatment device

a treatment device and substrate technology, applied in the direction of polycrystalline material growth, crystal growth process, chemically reactive gas, etc., can solve the problems of inconvenient etching gas consumption and particle generation, and achieve good etching characteristics and avoid particle generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]One embodiment of this invention will be described below based on the drawings.

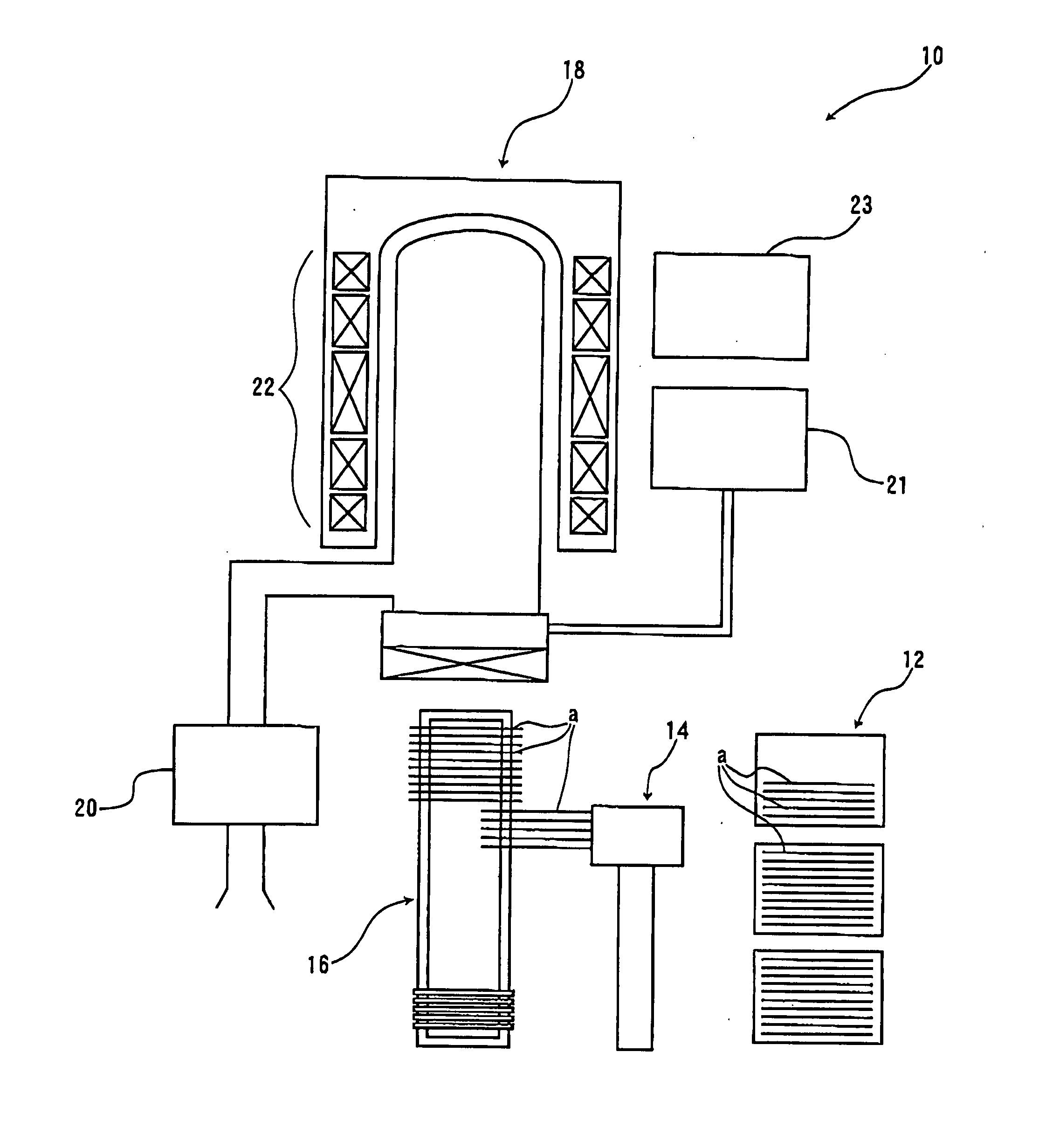

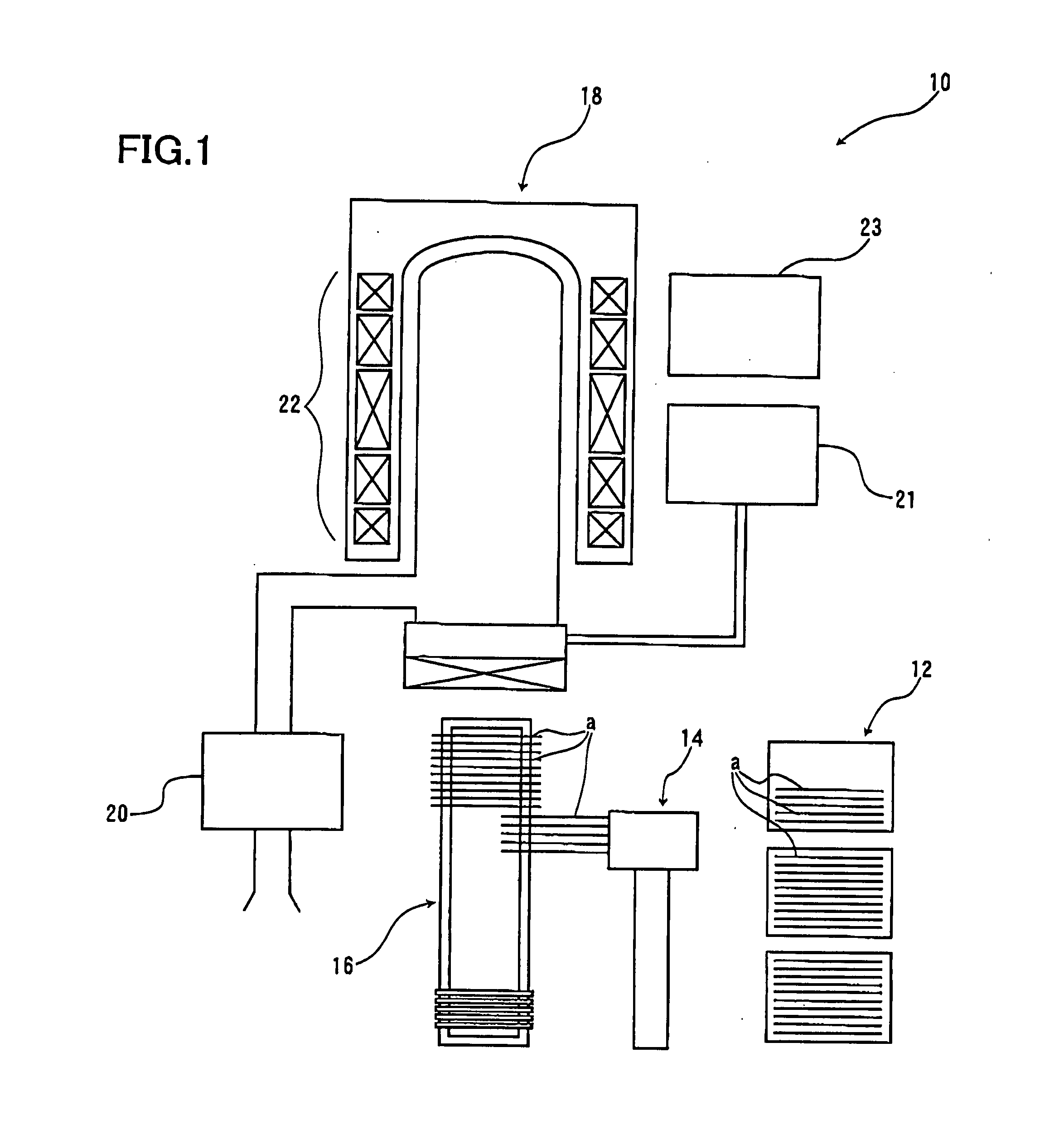

[0016]Shown in FIG. 1 is a schematic diagram of a substrate treatment device 10 according to one embodiment of this invention. The substrate treatment device 10 is a so-called hot wall type vertical low pressure CVD device.

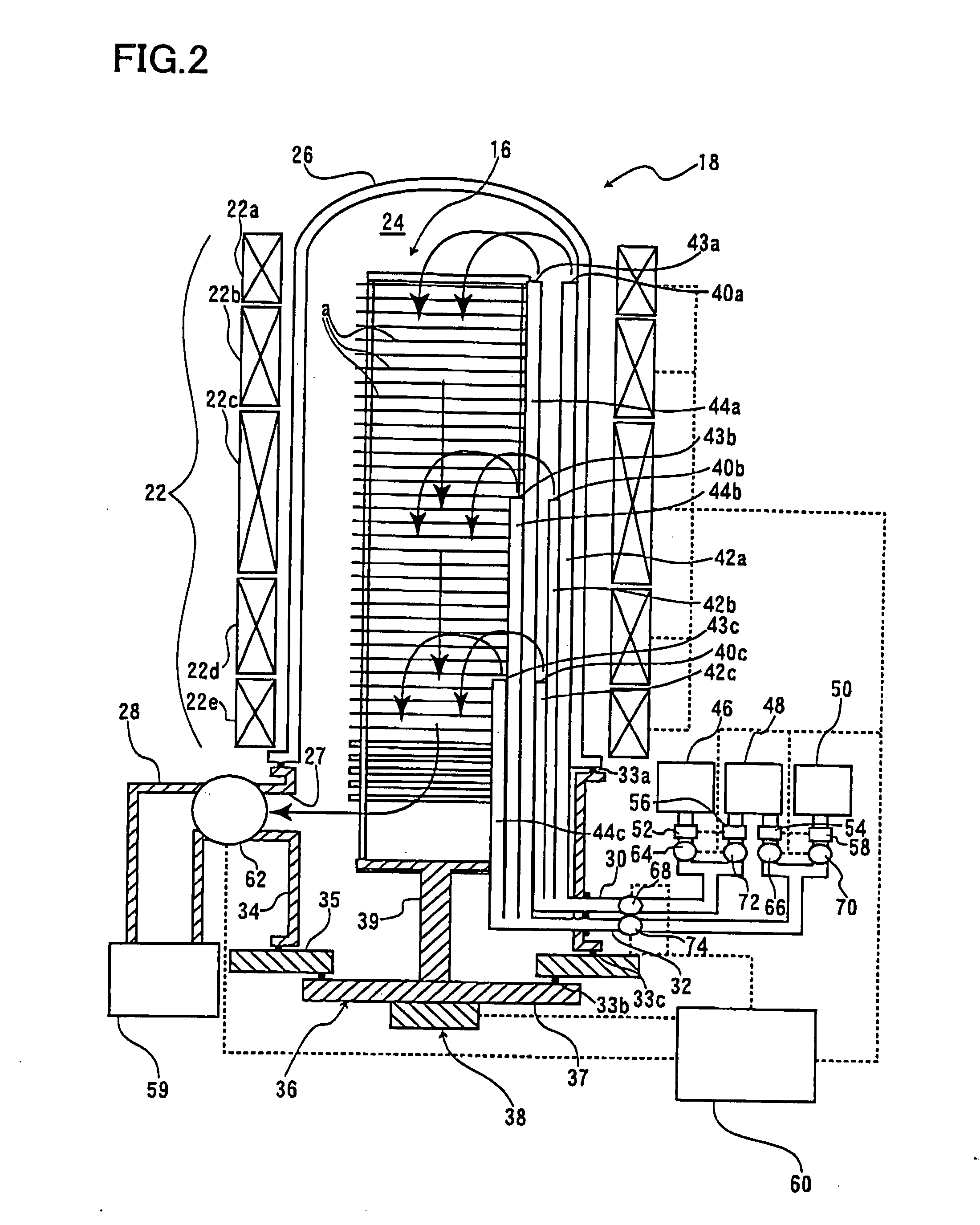

[0017]As shown in FIG. 1, wafers (Si substrates) a conveyed by a wafer cassette 12 are transferred onto a boat 16 from the wafer cassette 12 by a transfer machine 14. When transfer of all of the wafers a is finished, the boat 16 is inserted into a treatment furnace 18, and then the treatment furnace 18 is reduced in pressure by an evacuation system 20. Subsequently, a temperature inside the treatment furnace 18 is increased to a desired temperature by a heater 22, and, when the temperature becomes stable, a raw material gas and an etching gas are alternately supplied from a gas supply system 21 to cause selective epitaxial growth of Si, SiGe, or the like on the wafers a. Denoted b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com