Washing box component and washing machine with washing box component

A washing box and washing machine technology, applied in the field of washing machines, can solve the problems of less washing powder, difficult to remove dirt, washing powder waste, etc., and achieve the effects of preventing pollution and residue, improving user experience, and improving energy efficiency level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] As described in the background technology, when washing clothes, the existing washing machine puts detergent into the laundry box in advance, and after the washing machine program runs, the water flow entering through the water inlet valve directly flushes the area where the detergent is placed. The washing in the box will have certain residues, and the presence of washing in the washing box will adversely affect the performance of the washing machine. During the rinsing process, the washing and washing will not dissolve sufficiently, which will affect the cleaning effect of the clothes.

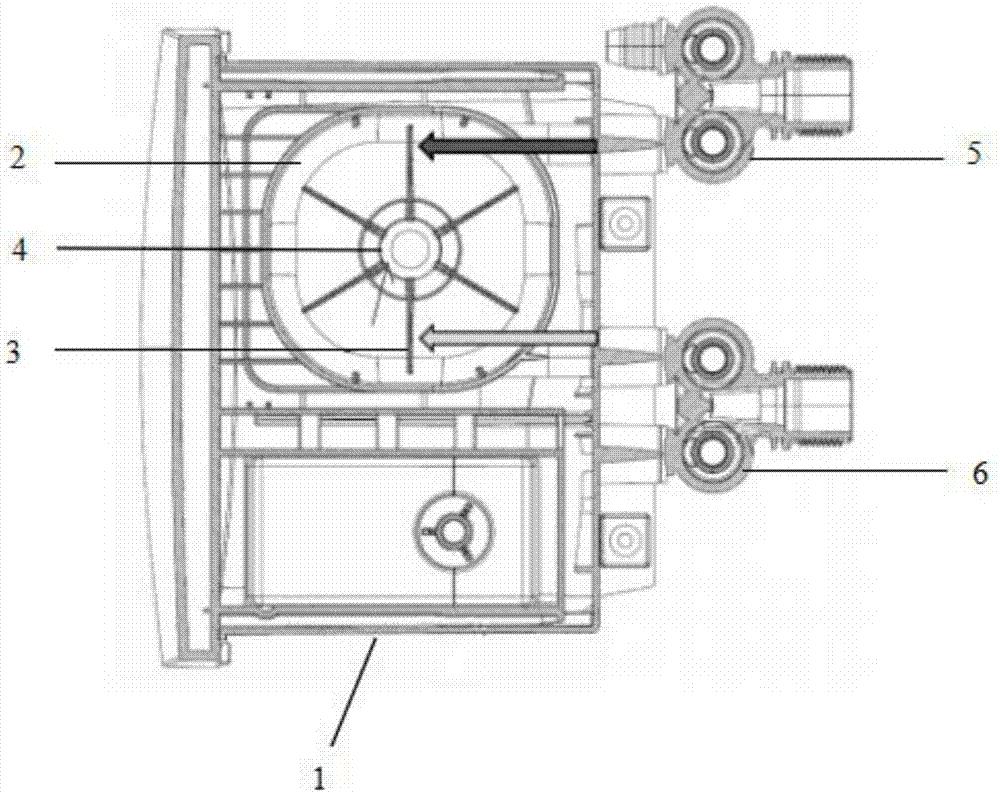

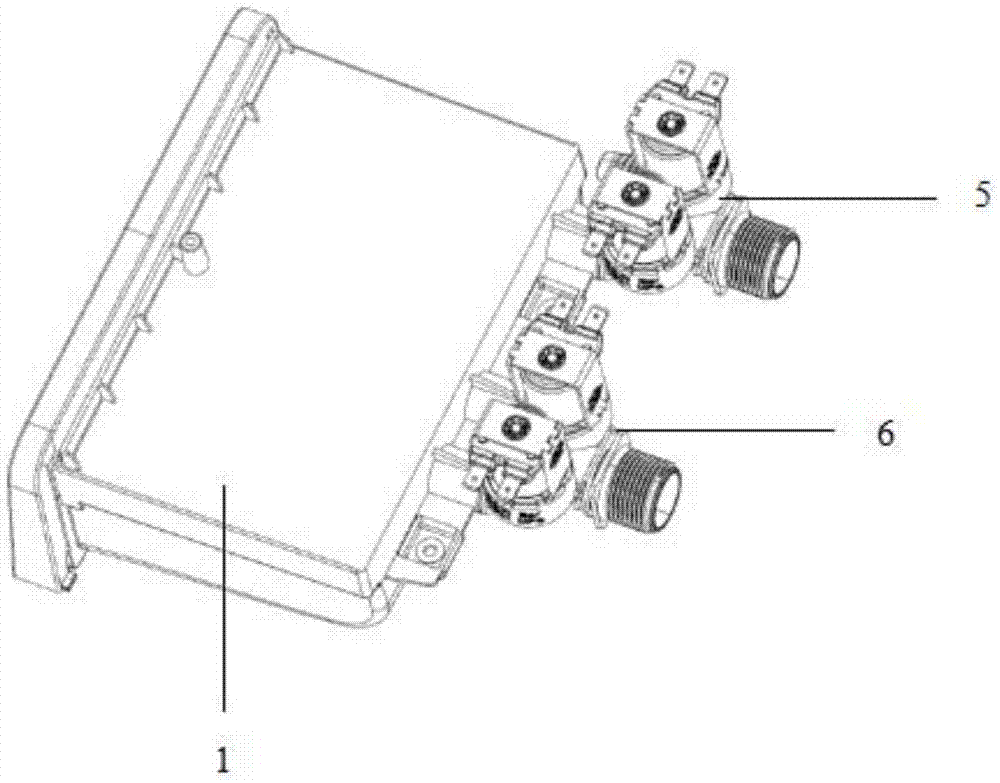

[0023] The washing box assembly of the washing machine in the present invention adds a turbine mechanism that can rotate repeatedly, so that the detergent can be fully dissolved and utilized. Next, the specific technical solution of the present invention will be introduced in detail.

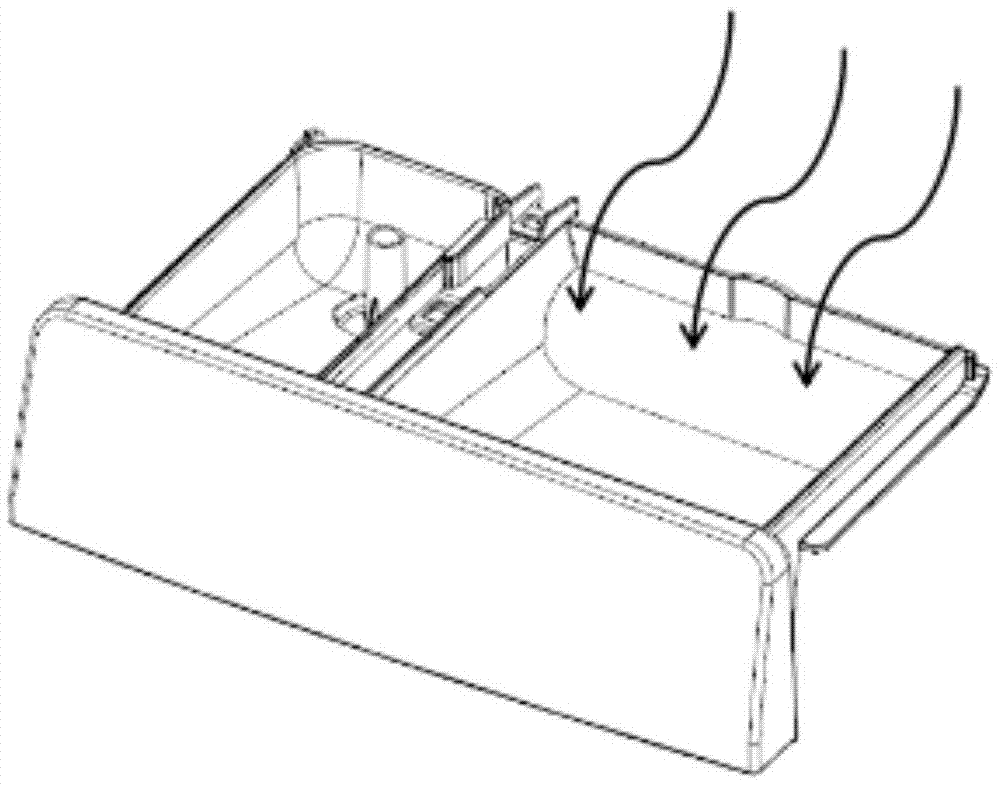

[0024] Please also see Figure 2 ~ Figure 3 , the washing box assembly of the washing machine in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com