Washing machine

A washing machine and inner drum technology, applied in the field of washing machines, can solve problems such as splashing of clothes, excessive water volume, and limited washing ability of clothes, and achieve the effects of reducing process complexity and production costs, washing clothes evenly, and improving cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The following describes in detail the embodiments of the present invention, examples of which are illustrated in the accompanying drawings. The embodiments described below with reference to the accompanying drawings are exemplary, and are intended to explain the present invention and should not be construed as limiting the present invention.

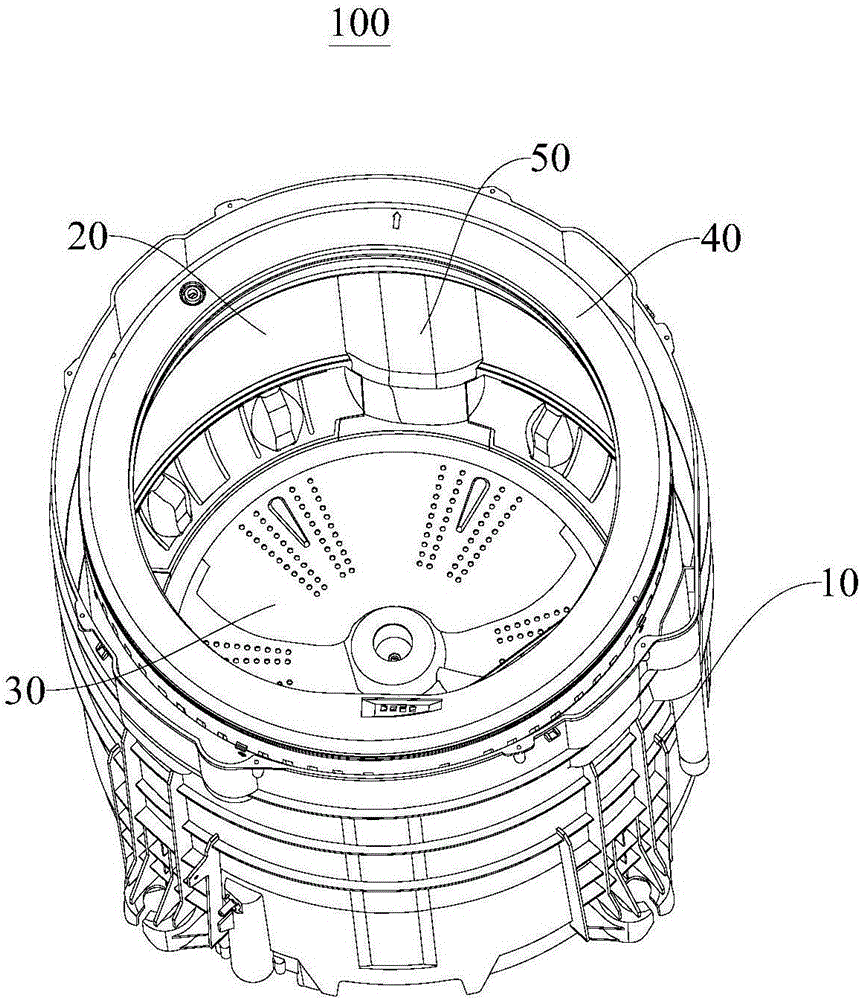

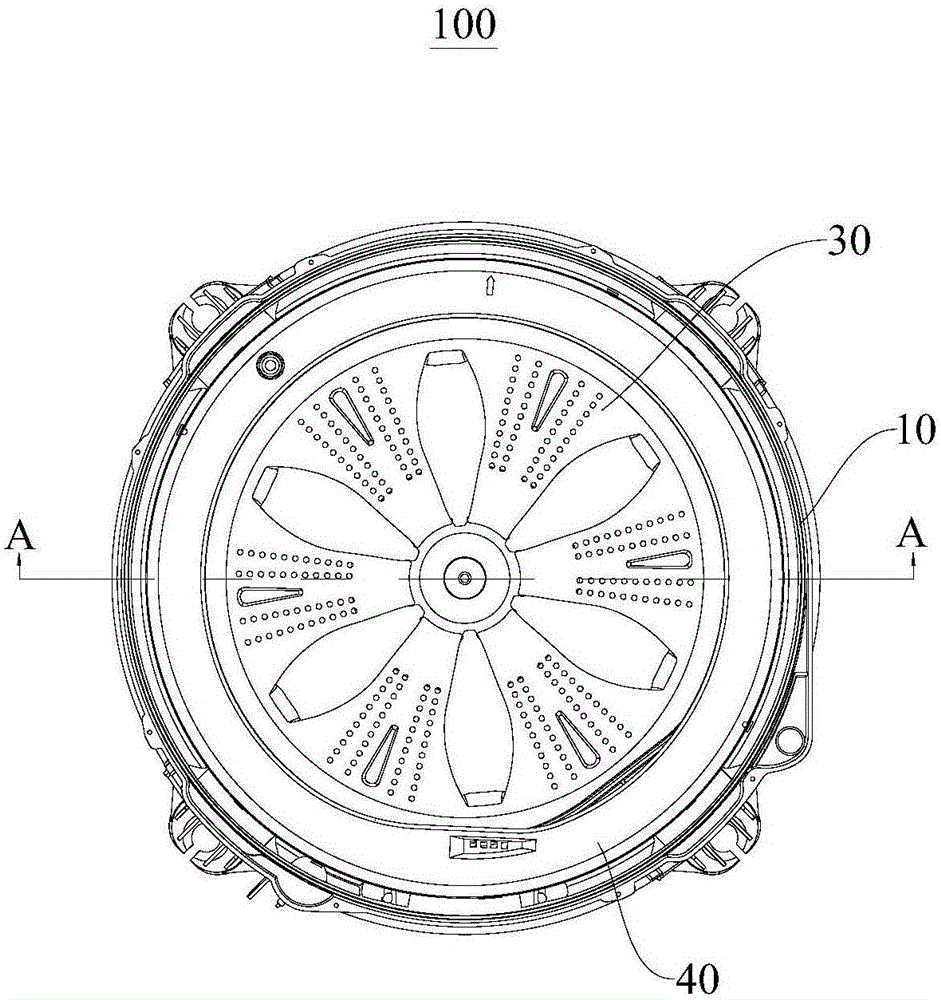

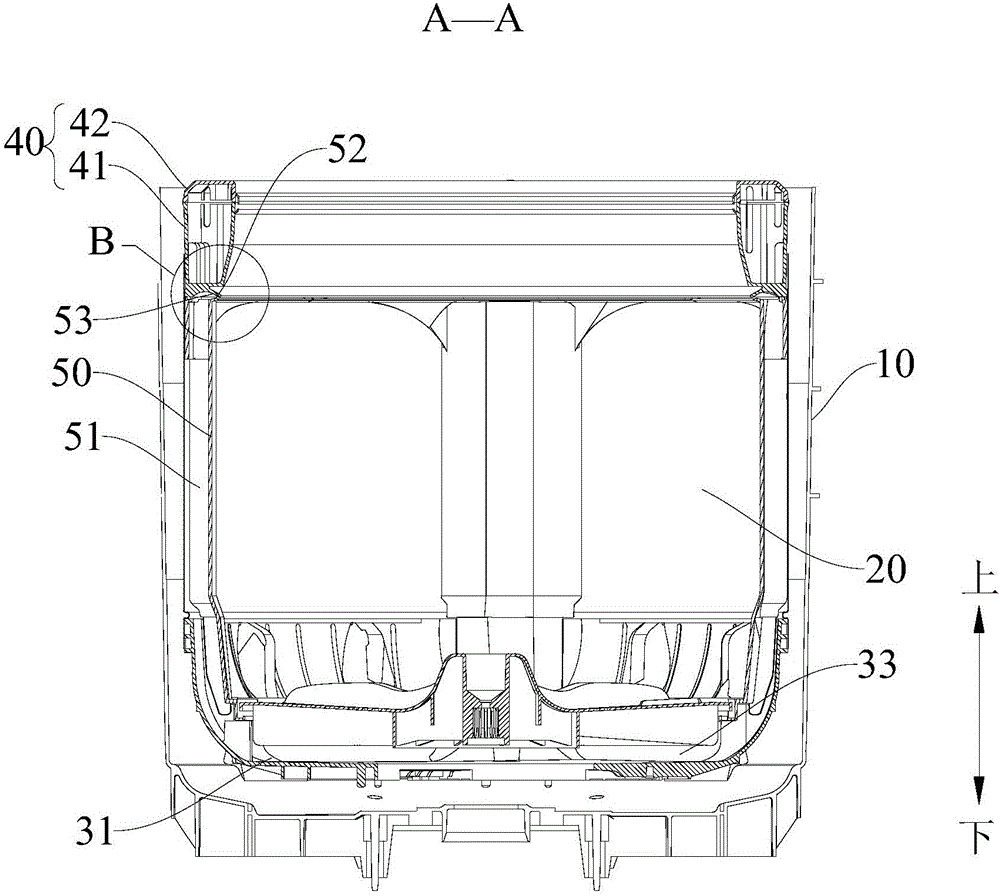

[0057]Attached below Figure 1 to Figure 15 The washing machine 100 according to the embodiment of the present invention is described in detail.

[0058] The washing machine 100 according to the embodiment of the present invention includes an outer tub 10 , an inner tub 20 , a pulsator 30 and a balance ring assembly 40 . Specifically, the inner cylinder 20 is arranged in the outer cylinder 10 and is spaced apart from the outer cylinder 10 , and the inner side wall of the inner cylinder 20 is provided with a plurality of water passage plates 50 which are spaced apart along the circumference thereof, and each water passage passage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size of the opening | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com