Impeller type fully-automatic washing machine and driving device thereof

A fully automatic washing machine, pulsator technology, applied to washing devices, other washing machines, washing machines with containers, etc., can solve the problems of unsatisfactory vibration damping effect, washing machine vibration, serious and other problems, achieve simple structure and improve washing ratio , the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

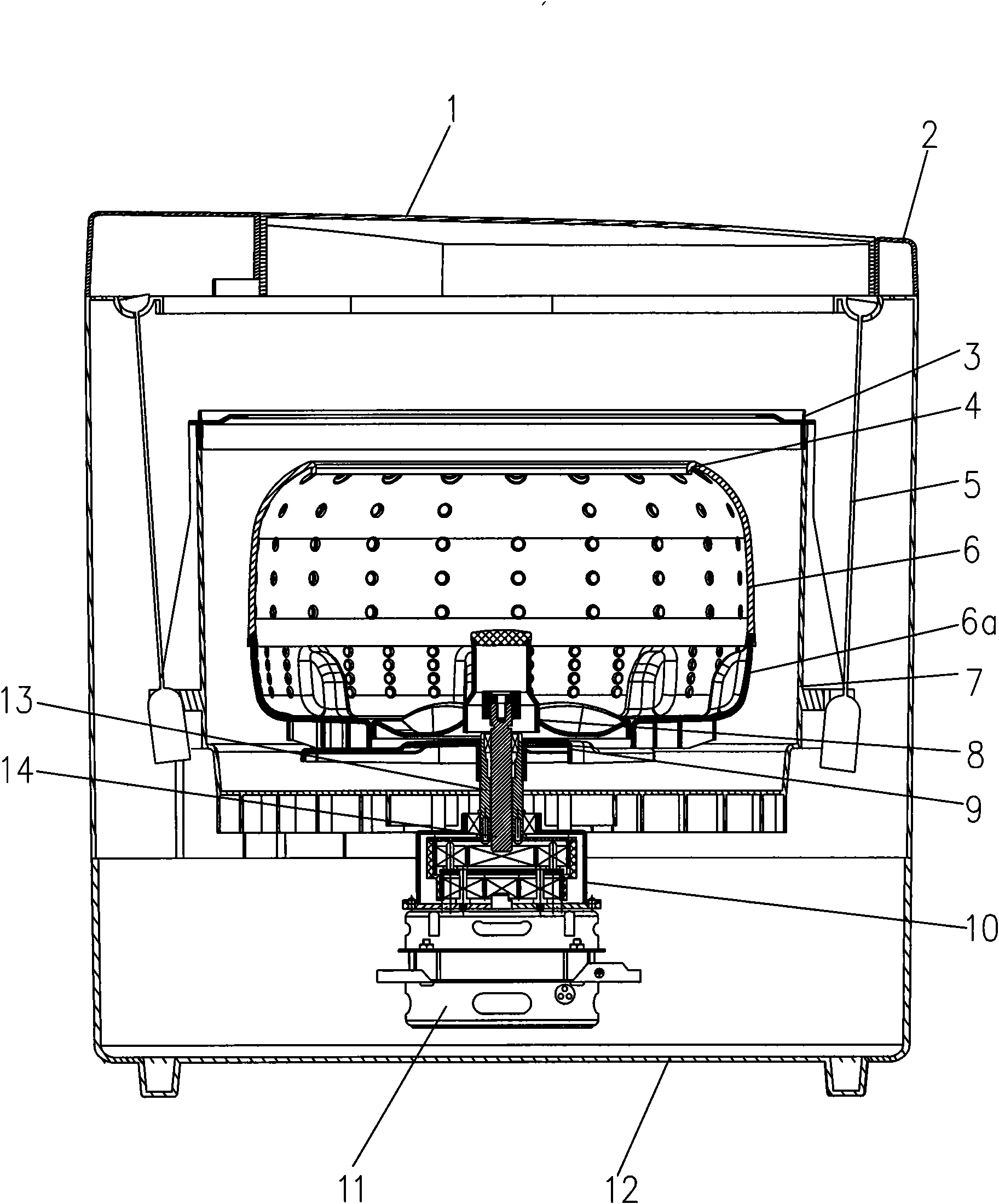

[0057] like figure 1 As shown, the washing machine of the present invention includes a base 12, a casing 2 placed on the base 12, a cover 1 that can be opened and closed is arranged on the top of the casing 2, and a water bucket 7 is arranged in the casing 2, and the water bucket 7 is mounted on Rod 5 is suspended on the top of shell 2, and bucket 7 top opening is provided with bung 3, is used for covering bucket 7, prevents the laundry water in bucket 7 from overflowing during washing process. A rotatable perforated dehydration bucket 6 is arranged in the water tub 7, and the clothes to be washed are placed in the perforated dehydration bucket 6.

[0058] like figure 1 As shown, the output shaft of the motor 11 is connected with the first central gear 20 of the transmission device 10 installed on its upper part, the transmission device 10 is connected with the dehydration bucket fixed plate 9 through the dehydration bucket shaft 13, and connected with the pulsator 8 throug...

Embodiment 2

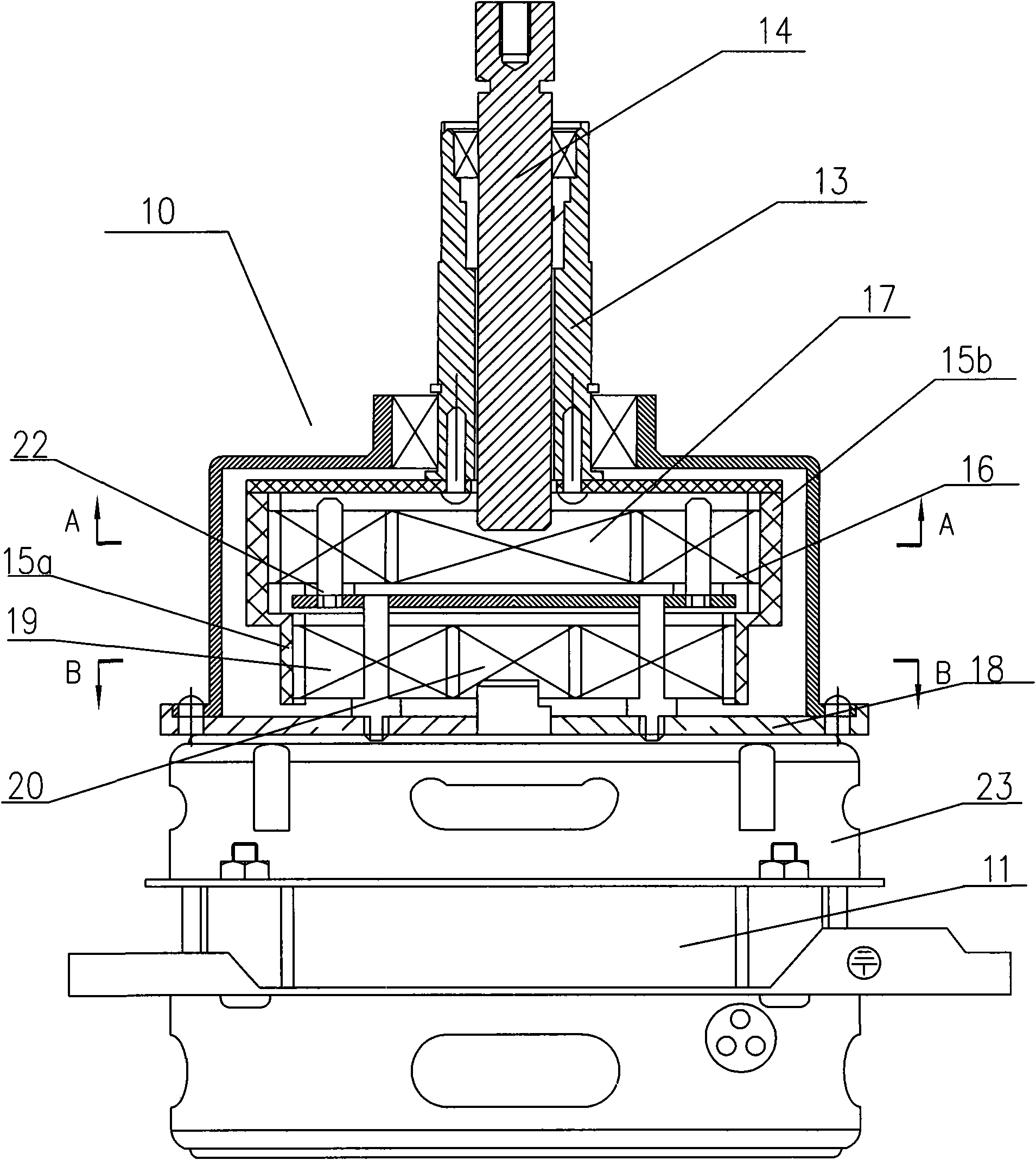

[0078] like image 3 , 4 As shown, the output shaft of the motor 11 is connected with the first sun gear 20 and the second sun gear 17 of the transmission device 10 installed on its upper part. The transmission device 10 is connected to the dehydration bucket fixed plate 9 through the dehydration bucket shaft 13 , and is connected to the pulsator 8 through the pulsator shaft 14 . The dehydration bucket 6 is integrated with the dehydration bucket fixed plate 9, so the dehydration bucket 6 can be driven to rotate when the dehydration bucket shaft 13 rotates. The pulsator shaft 14 is enclosed within the dehydration bucket shaft 13, and its upper end is connected to the pulsator 8 positioned at the center of the bottom of the dehydration bucket 6, so when the pulsator shaft 14 rotates, the pulsator 8 can be driven to rotate, and the dehydration bucket 6 is located inside the water storage bucket 7. Two water outlets are arranged at the bottom of the bucket 7 both sides, and the ...

Embodiment 3

[0091] Refer to as Figure 5 As shown, the washing machine and its transmission device according to Embodiment 3 of the present invention will be described.

[0092] The central position of the bottom of the washing machine tub 7 is equipped with a transmission device 10, and a motor 11 is installed at the bottom center position of the transmission device 10 to directly transmit power to the transmission device 10.

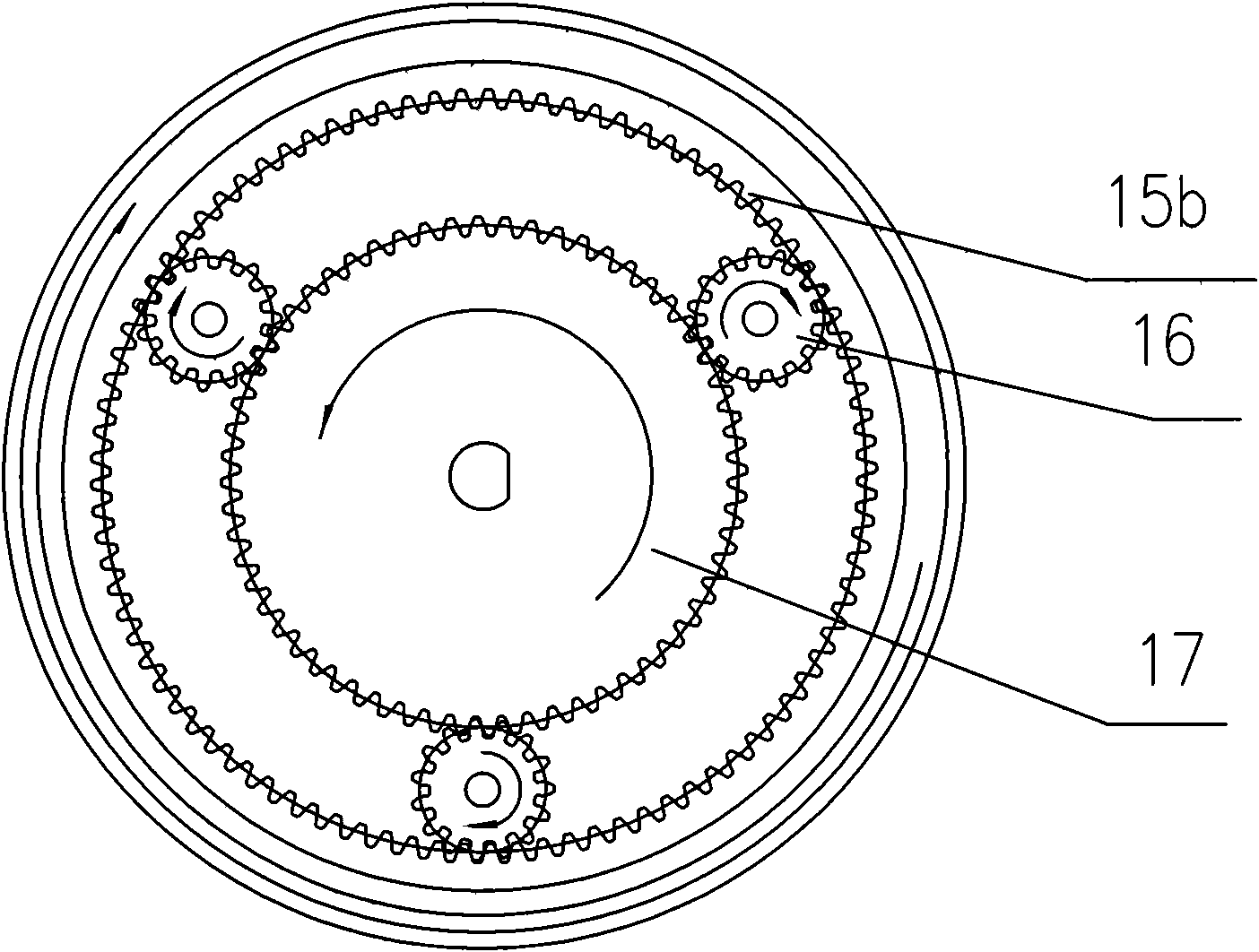

[0093] Image 6 is the main section of the transmission 10, Figure 6a along Image 6 In the cross-sectional view of line A-A in the center, a set of planetary reduction gears is installed in the transmission device 10, including a central gear 17a, an outer planetary gear 15' and 3 or 4 planetary gears 16a, 16b, and the three planetary gears 16a, 16b are arranged on the central gear 17a and the outer planetary gear 15' and meshes with it. One of the planetary gears 16a is connected with the motor shaft 11a, and the other 2 or 3 planetary gears 16b are fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com