Plasma processing apparatus, method for producing reaction vessel for plasma generation, and plasma processing method

A plasma and processing device technology, applied in the field of plasma processing devices, can solve the problems of increased gas operating costs and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

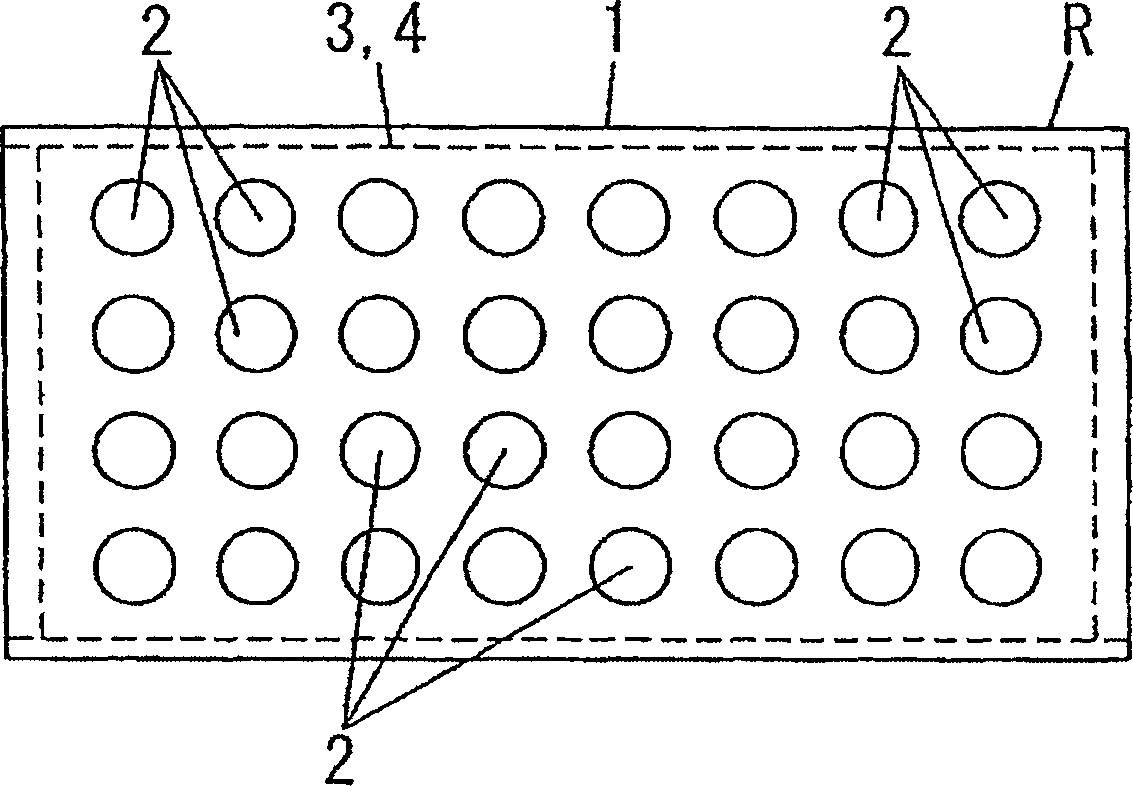

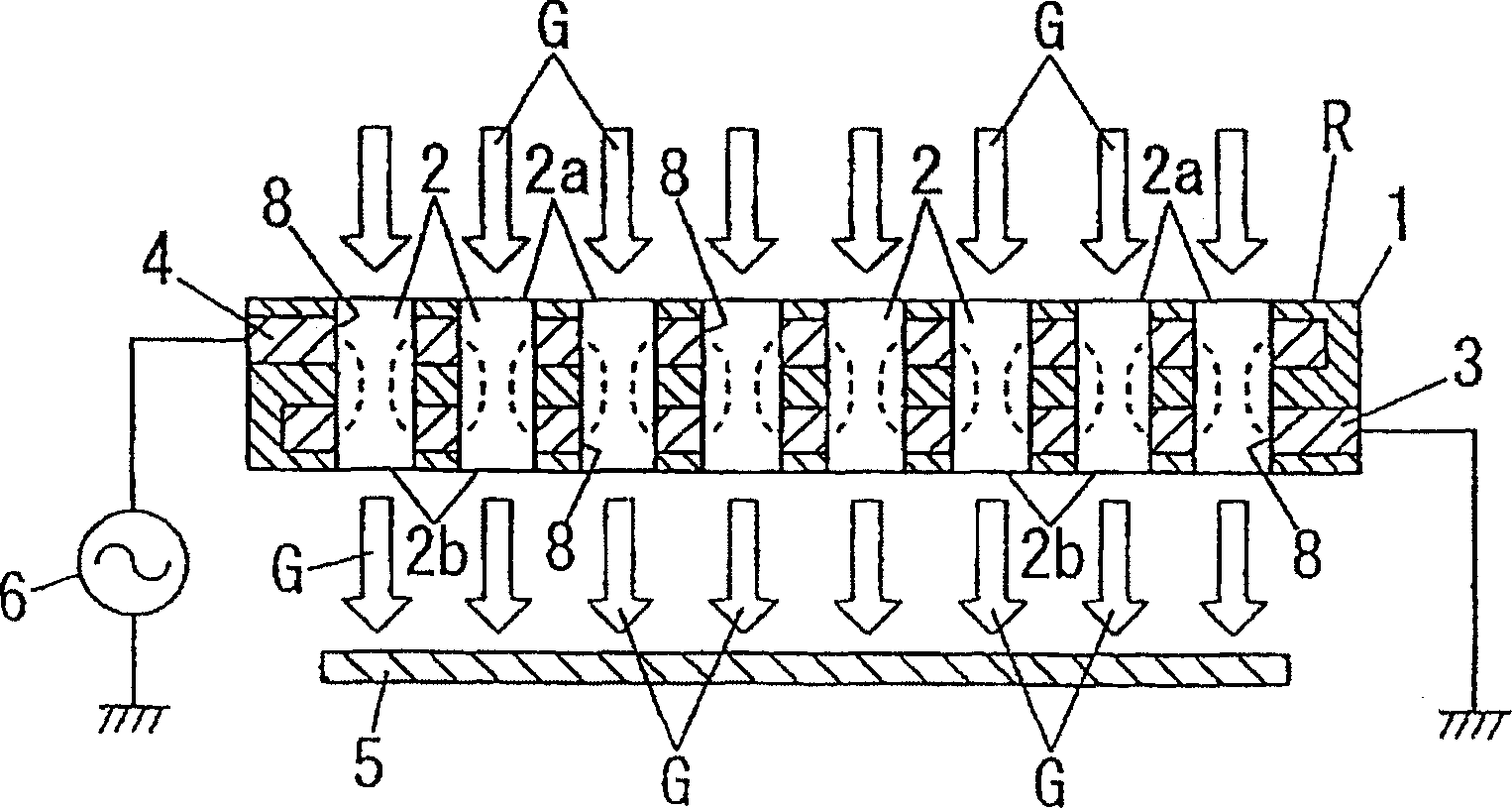

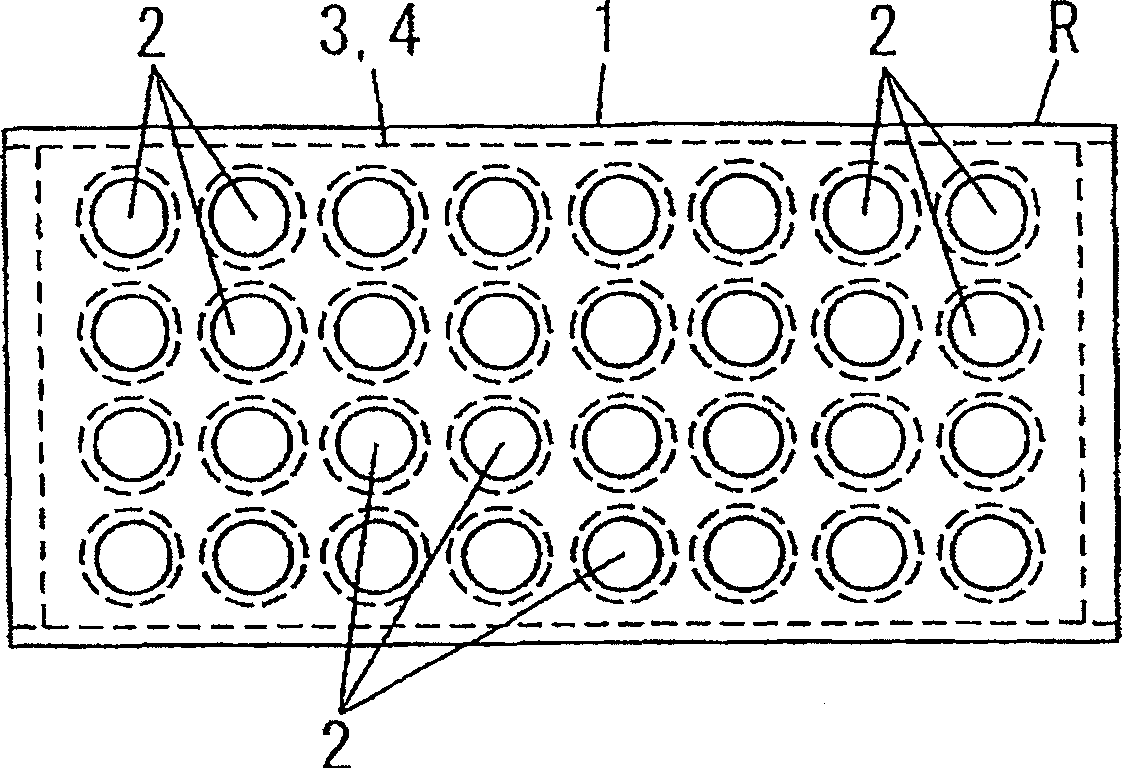

example 1

[0125] A conductive film was formed on the surface of the first board (thickness: 0.4 mm) by printing, and then the second board (thickness: 1.4 mm) was placed on the conductive film. Further, a conductive film was formed on the surface of the second board by printing, and then a third board (thickness: 1.4 mm) was placed on the conductive film. In this embodiment, each of the first to third plates is obtained by forming a material containing alumina powder into a plate shape. Each plate has a plurality of apertures, each aperture having a diameter of 1 mm. The plates are placed in layers such that the aperture positions of the individual plates correspond to each other. The conductive film is formed by printing a tungsten layer. A plurality of apertures 8 (each having a diameter of 3 mm, larger than the apertures of the plates) were formed in the conductive film such that each aperture of the plates was placed in each aperture of the conductive film. The stack thus obtaine...

example 2

[0129]A conductive film was formed on the surface of the first board (thickness: 0.7 mm) by printing, and then the second board (thickness: 1.5 mm) was placed on the conductive film. Each of the first and second plates was formed by forming an alumina-containing material into a plate shape, as in the case of Example 1. Each of the first and second plates had a plurality of slit-like apertures each having a width of 1 mm and a length of 22 mm in plan view thereof. The plates are placed in layers such that the positions of the slit-like apertures of the plates correspond to each other. The conductive film was formed by printing a tungsten layer, as in the case of Example 1. In this embodiment, each conductive film is formed in a comb pattern. The stack thus obtained is sintered to obtain a Figure 3A with 3B Reaction vessel R of the structure shown.

[0130] In this embodiment, the insulating member 1 of the reaction container has a thickness of 2.2 mm, and eleven slit-shap...

example 3

[0133] The plasma processing apparatus used in this embodiment is basically the same as that of Example 1, except that the diameters of the pores 8 and the through holes 2 of the electrodes 3, 4 are 1 mm, and the inner surfaces of the pores 8 of the electrodes 3, 4 are exposed to inside of via 2, as Figure 10 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com