Method and apparatus having plate electrode for surface treatment using capillary discharge plasma

a technology of capillary discharge plasma and surface treatment, which is applied in the direction of cleaning processes and apparatuses, electric discharge tubes, chemistry apparatuses and processes, etc., can solve the problems that the background art plasma process cannot be used to treat the workpiece and the application of background art plasma processes is limited

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Reference will now be made in detail to the present illustrated embodiments of the invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

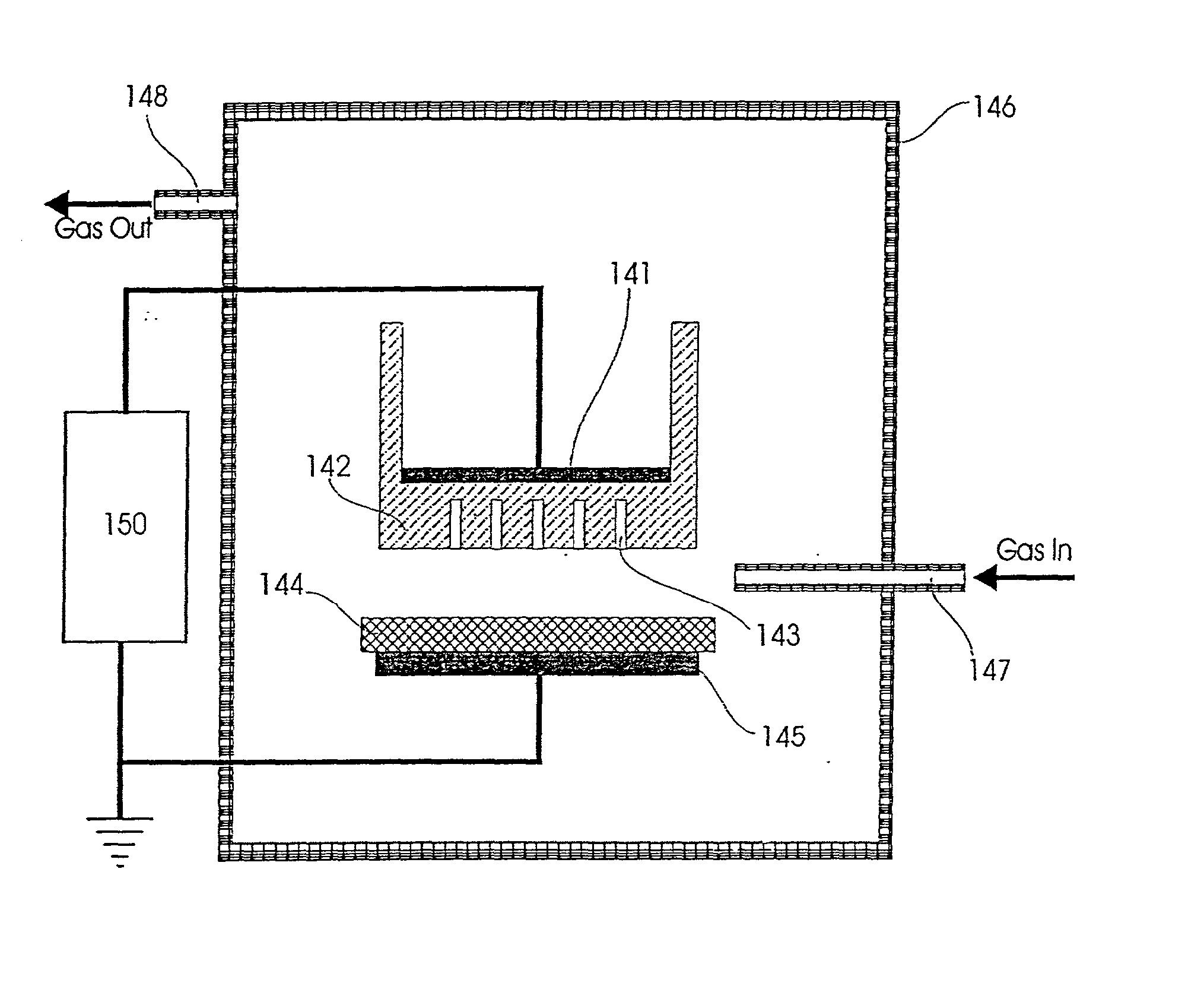

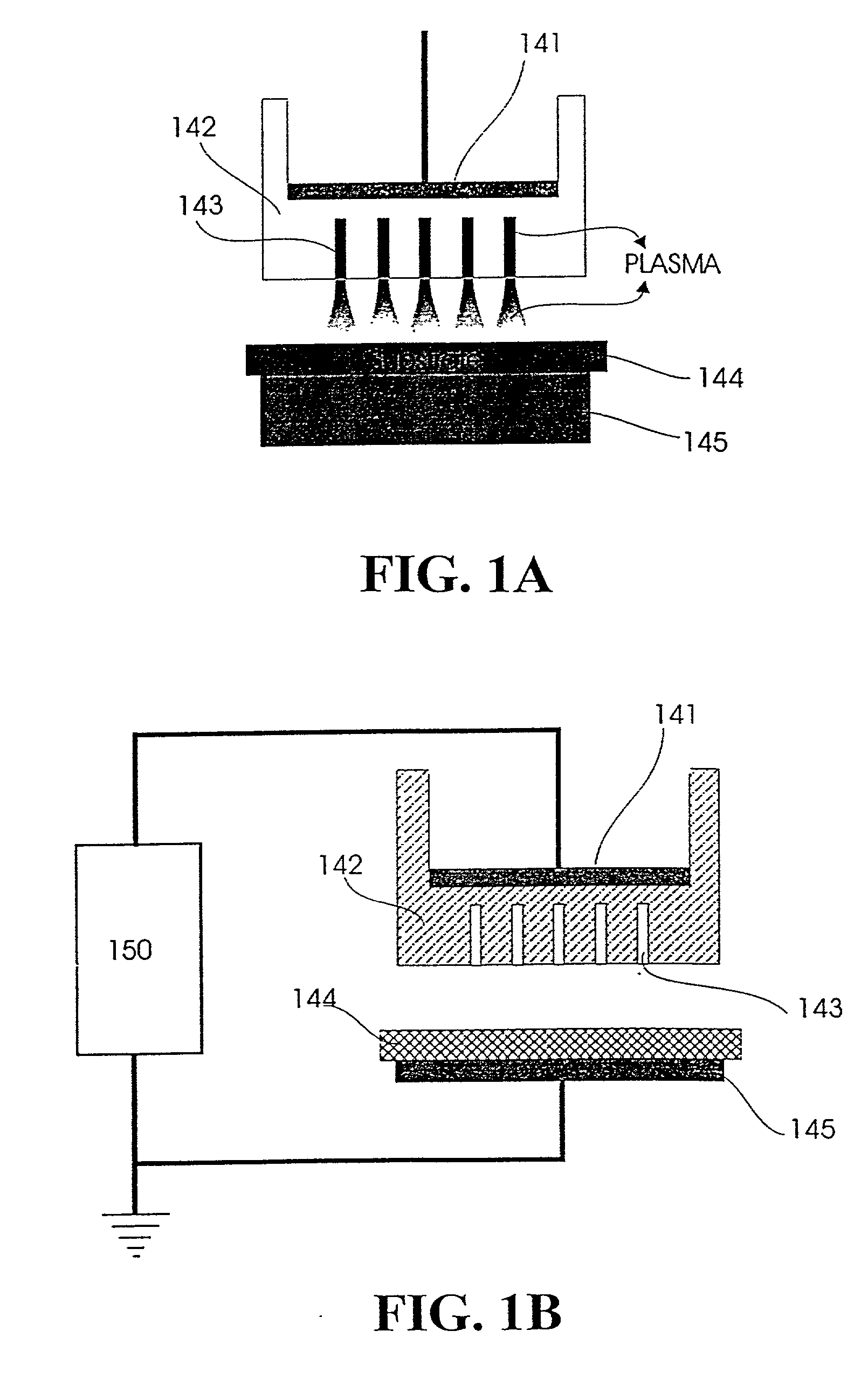

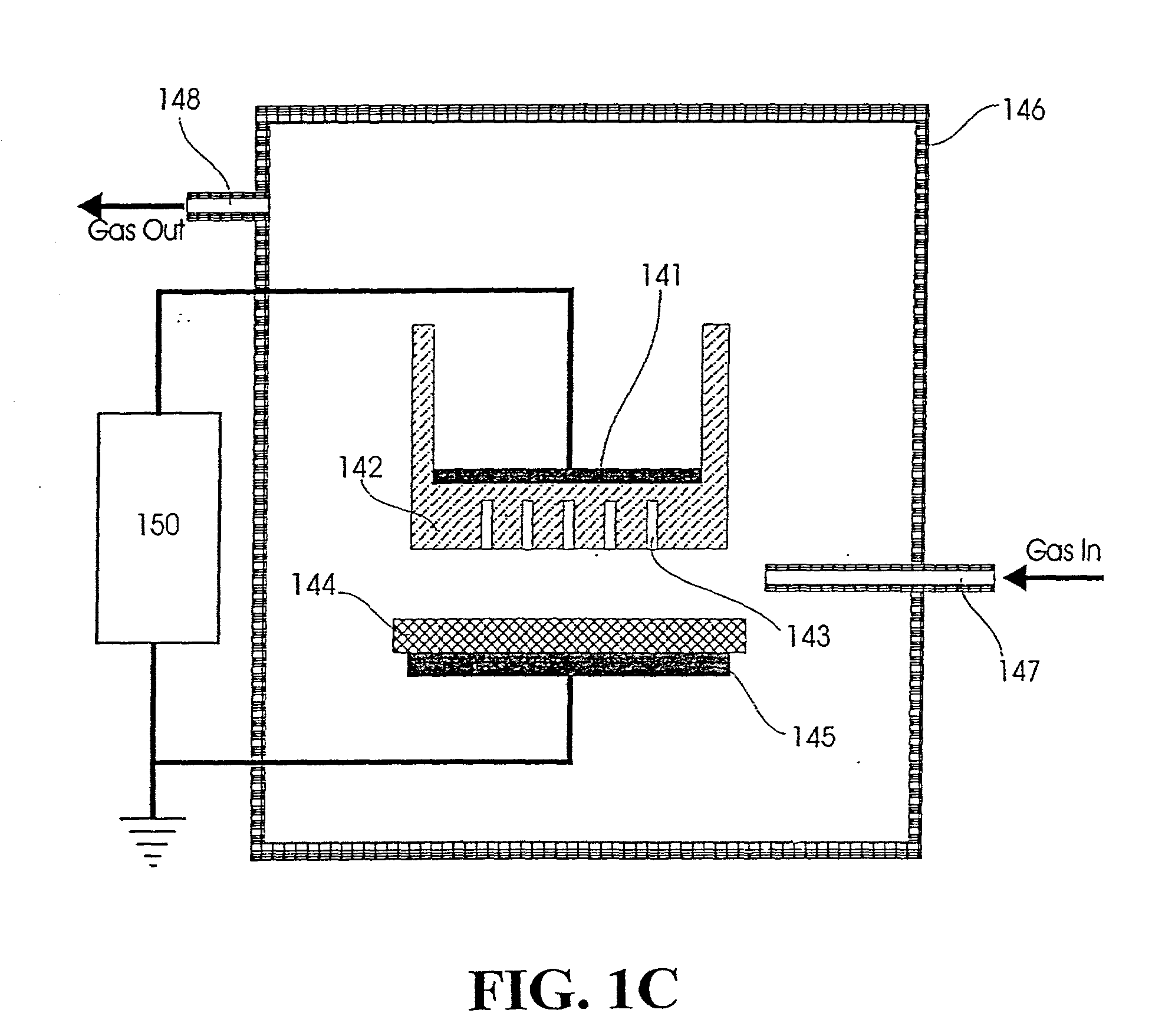

[0029] FIG. 1A is a schematic cross-sectional view of an embodiment of a capillary discharge plasma head for surface treatment for conductive workpieces. The apparatus includes at least one plate electrode 141, a dielectric body 142, at least one capillary 143 formed in the dielectric body 142 and extending substantially therethrough, and a counter-electrode 145, wherein a workpiece 144 is placed. The apparatus discharges plasma through the capillaries and onto the conductive workpiece 144. Throughout the present invention, the plate electrode 141 may consist of more than one plate. Moreover, there is no critical geometry for the plate electrode 141 as long as the plate electrode matches all of the capill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com