Water-based cleaning agent for electronics and preparation method thereof

A technology of cleaning agent and electronic water, which is applied in the direction of detergent compounding agent, detergent composition, chemical instruments and methods, etc., and can solve the problems of solvent-based cleaning agent products with uneven quality, unsatisfactory cleaning effect, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] In parts by weight, it includes: 50 parts of ethylene glycol monobutyl ether, 29.5 parts of propylene glycol monomethyl ether, 10 parts of monoethanolamine, 0.5 parts of benzotriazole, and 10 parts of AEO-9;

[0013] Mix 50 parts of ethylene glycol monobutyl ether, 29.5 parts of propylene glycol monomethyl ether, 10 parts of monoethanolamine, 0.5 parts of benzotriazole, and 10 parts of AEO-9, and stir evenly;

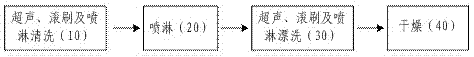

[0014] Such as figure 1 As shown, the cleaning agent is mixed with water at a mass ratio of 1:4 and heated to 60°C. Deionized water is used for rinsing at a temperature of 50°C; the PCBA out of the furnace is put into the cleaning tank for 5 minutes of ultrasonic wave and then rinsed once. Rinse the tank until it is clean, then dry it, and wait for detection.

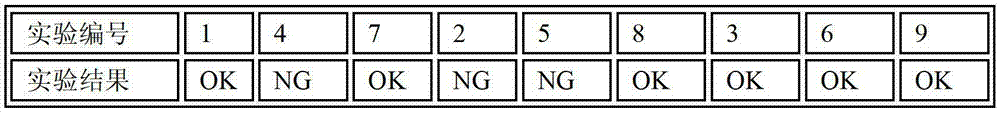

[0015] 1. Cleaning effect experiment:

[0016] Experimental equipment: 3 ultrasonic cleaning equipment, 1 hair dryer, 9 computer motherboards;

[0017] Experimental samples: imported electronic water-ba...

Embodiment 2

[0036] In parts by weight, including: 30 parts of ethylene glycol monoethyl ether, 20 parts of diethylene glycol monoethyl ether, 19.5 parts of propylene glycol monomethyl ether, 10 parts of dipropylene glycol monomethyl ether, 6 parts of monoethanolamine, 4 parts of triethanolamine, AEO -9: 4 parts, OP-106 parts, benzotriazole 0.3 parts, T7010.2 parts.

[0037] 30 parts of ethylene glycol monoethyl ether, 20 parts of diethylene glycol monoethyl ether, 19.5 parts of propylene glycol monomethyl ether, 10 parts of dipropylene glycol monomethyl ether, 6 parts of monoethanolamine, 4 parts of triethanolamine, AEO-9: 4 parts, Mix OP-106 parts, benzotriazole 0.3 parts, T7010.2 parts, and stir evenly;

[0038] The cleaning agent is mixed with water at a mass ratio of 1:3 and heated to 60°C, rinsed with deionized water at a temperature of 50°C; put the PCBA out of the furnace into the cleaning tank for 5 minutes and then put it into the rinse tank for rinsing until Clean and dry, pend...

Embodiment 3

[0060] In parts by weight, including: 25 parts of diethylene glycol monobutyl ether, 25 parts of diethylene glycol monoethyl ether, 20 parts of propylene glycol monomethyl ether, 20 parts of dipropylene glycol monomethyl ether, 1 part of monoethanolamine, 1 part of diethanolamine , 1 part of triethanolamine, 1 part of hydroxyethylethylenediamine, 1 part of AEO, 1 part of NP, 1 part of OP, 1 part of TX, and 2 parts of LAS.

[0061] 25 parts of diethylene glycol monobutyl ether, 25 parts of diethylene glycol monoethyl ether, 20 parts of propylene glycol monomethyl ether, 20 parts of dipropylene glycol monomethyl ether, 1 part of monoethanolamine, 1 part of diethanolamine, 1 part of triethanolamine, Mix 1 part of hydroxyethylethylenediamine, 1 part of AEO, 1 part of NP, 1 part of OP, 1 part of TX, and 2 parts of LAS, and stir evenly;

[0062] The cleaning agent is mixed with water at a mass ratio of 1:3 and heated to 60°C, rinsed with deionized water at a temperature of 50°C; put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com