Integral replacing method of ladle turret with limited upper lifting space

A large-bale turntable and overall replacement technology, which is applied in the field of metallurgical machinery and equipment installation and construction, can solve problems such as difficult equipment binding, easy eccentricity, and small lifting height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

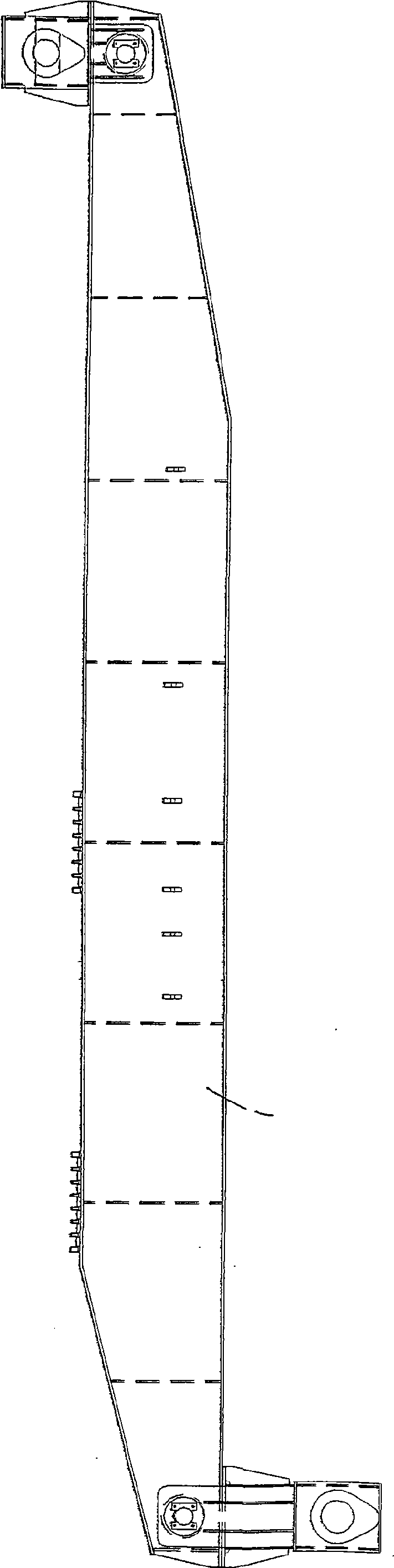

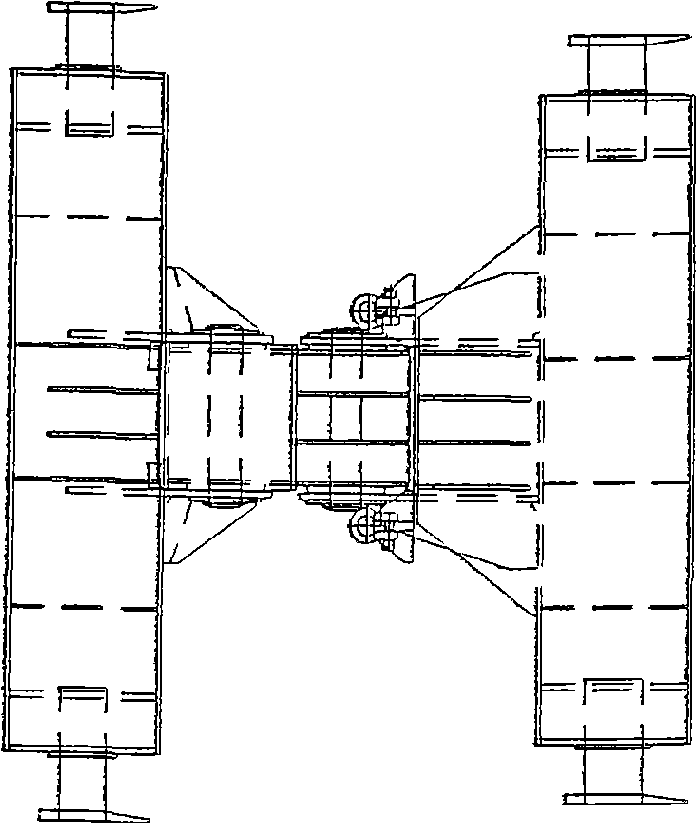

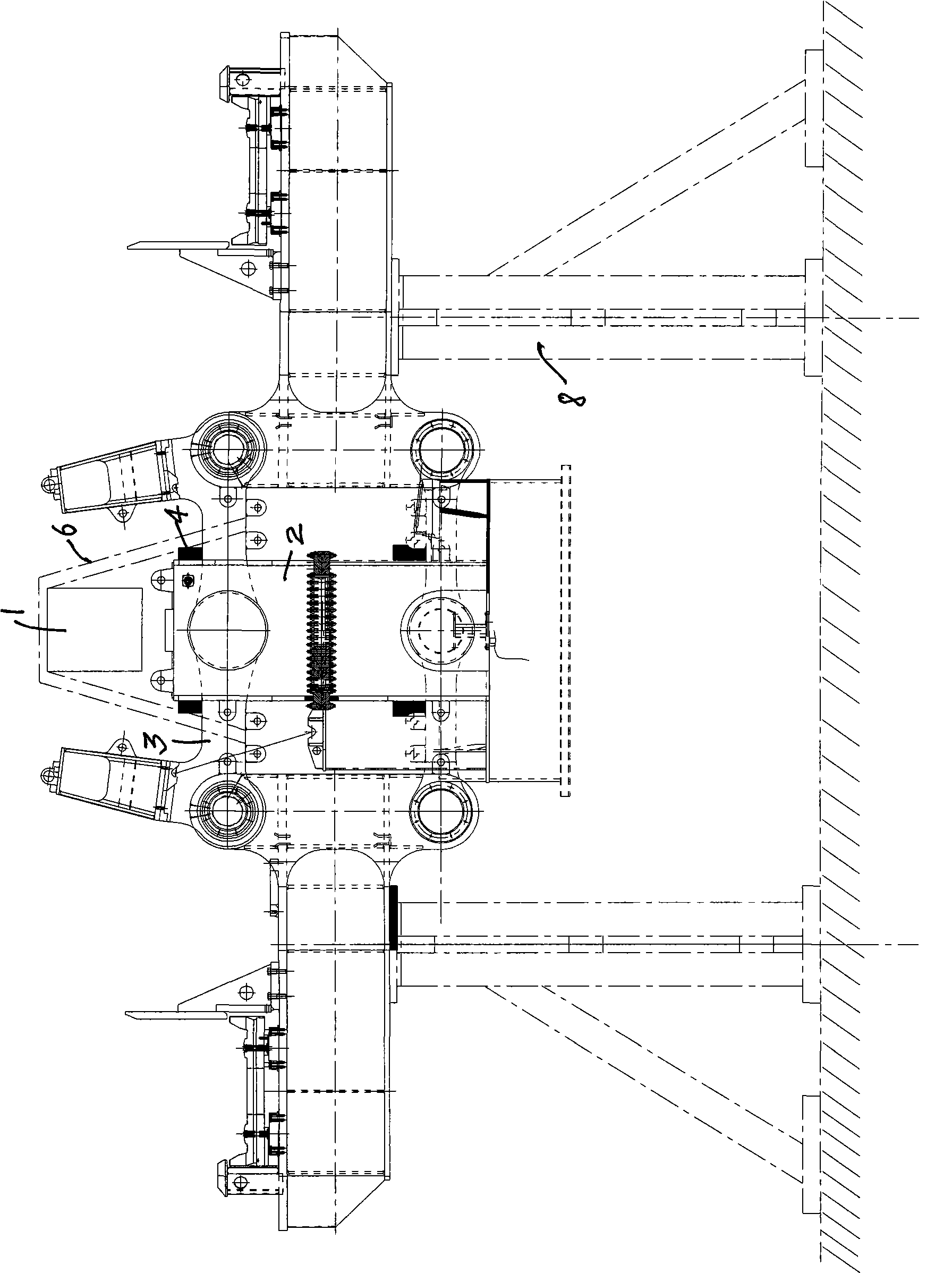

Image

Examples

Embodiment Construction

[0028] The ladle turntable of Meishan Steelmaking 2# machine was put into production in October 2002. The slewing bearing was replaced in April 2007. During the replacement, it was found that the slewing body under the B-arm lifting support was deformed and the slewing bearing connecting flange was deformed. There were major problems. Security risks.

[0029] 1. The weight of the ladle turret

[0030] Preface

No Part Name

unit

weight

Remark

1 Parts above the slewing bearing of the old ladle turret t 165 tear down 2 Old steel ladle turret slewing bearing and base t 22 tear down 3 appendix t 33 tear down 4 New ladle turret slewing bearing and above components t 190 Install 5 New ladle turret slewing bearing and base t 24 Install 6 appendix t 36 Install

[0031] 2. Engineering Features

[0032] 1. The removal and installation of the equipment requires a lot of work, and the maximum li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com