Rotary bearing flange of portal jib crane

A portal crane, slewing bearing technology, applied in cranes, bottom support structures, hoisting equipment braking devices, etc., can solve problems such as difficulty in ensuring quality, difficulty, and difficulty in quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

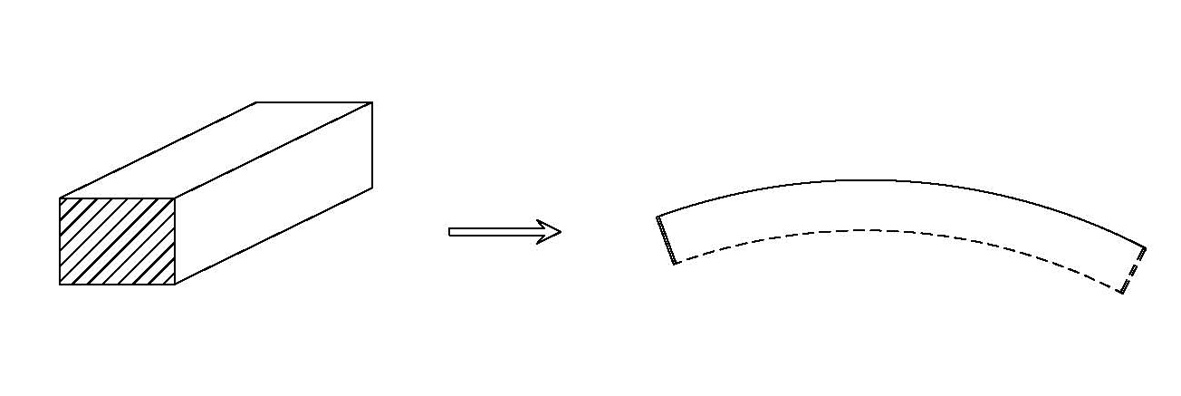

[0029] figure 1 It is a schematic diagram of the manufacturing process of the equally divided ring block. As shown in the figure, the flange 1 is made of small forgings of 25# steel, and after the required size is adjusted, it is divided into small sections and forged into long rods and squares. After heat treatment and mechanical processing, it is pressed by a hydraulic press. desired linetype. Compared with the overall forging, the forging is smaller, which can save a lot of money.

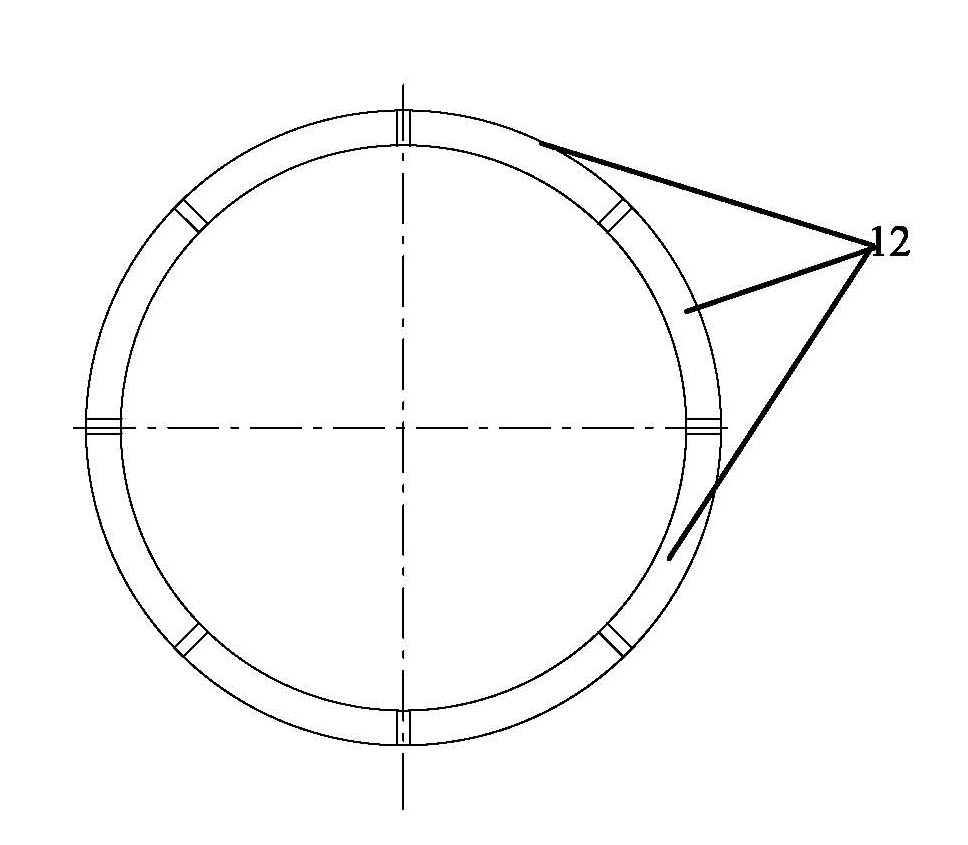

[0030] figure 2 It is a schematic diagram of ring tailor welding. As shown in the figure, eight small forgings that have been cold-pressed into arcs are beveled and cut off, then assembled on the platform, and then welded into a ring, and finally welded into a ring flange for finishing to the specified size.

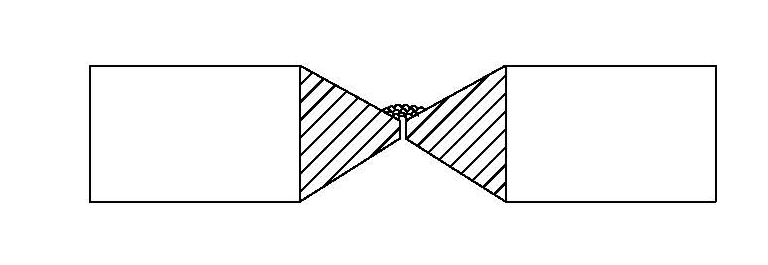

[0031] Such as Figures 3 to 6 As shown, in order to solve the problems of stress concentration, welding deformation, difficult machining, difficult positioning of bolt holes and hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com