Method for dismounting and replacing ladle turret revolving bearing

A large-pack rotary table and slewing bearing technology, which is applied to metal processing equipment, manufacturing tools, casting molten material containers, etc., can solve problems such as abnormal wear of grease, damage to slewing bearings, and difficult lifting positions, etc. Economic benefit and maintenance time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

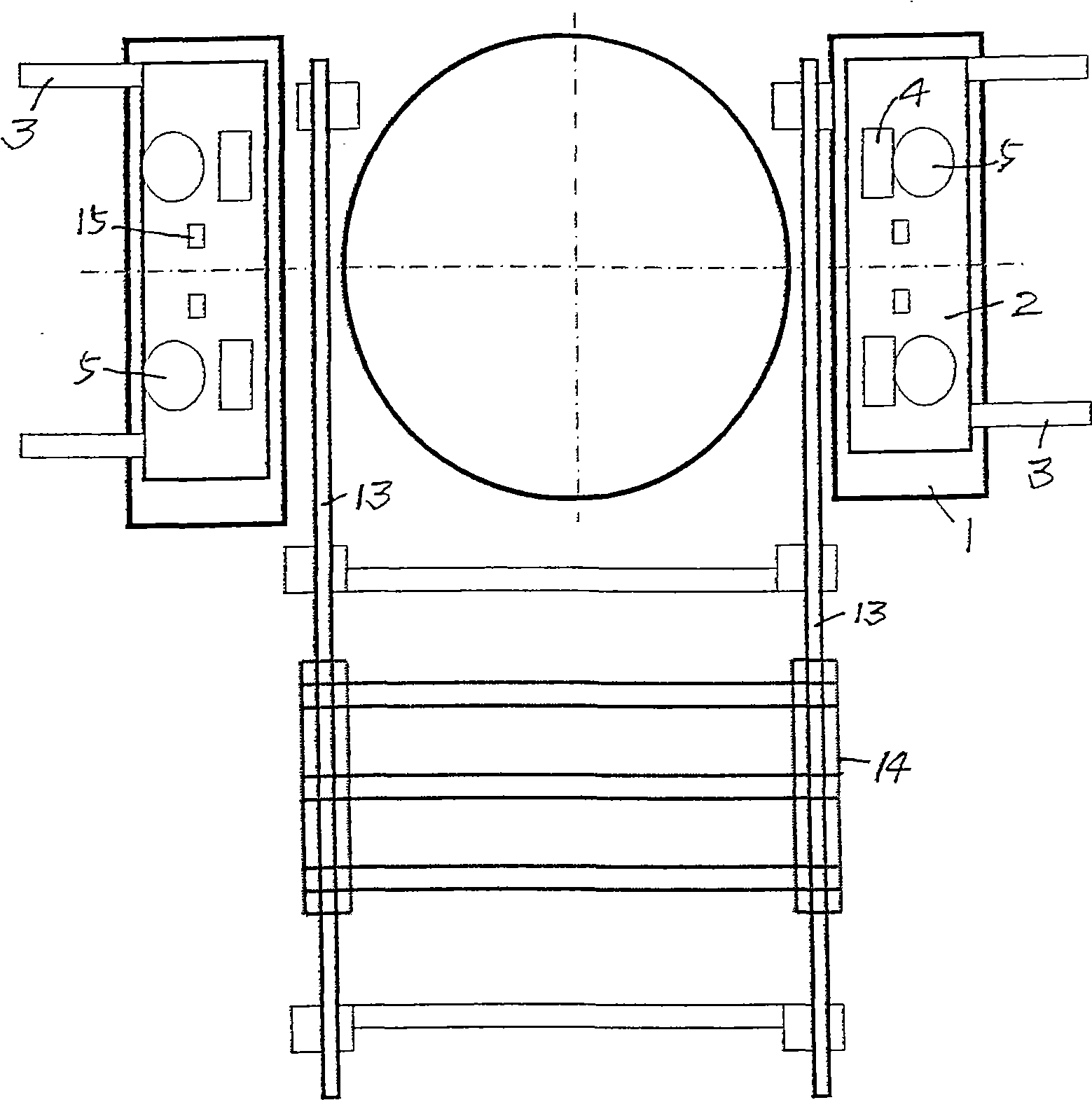

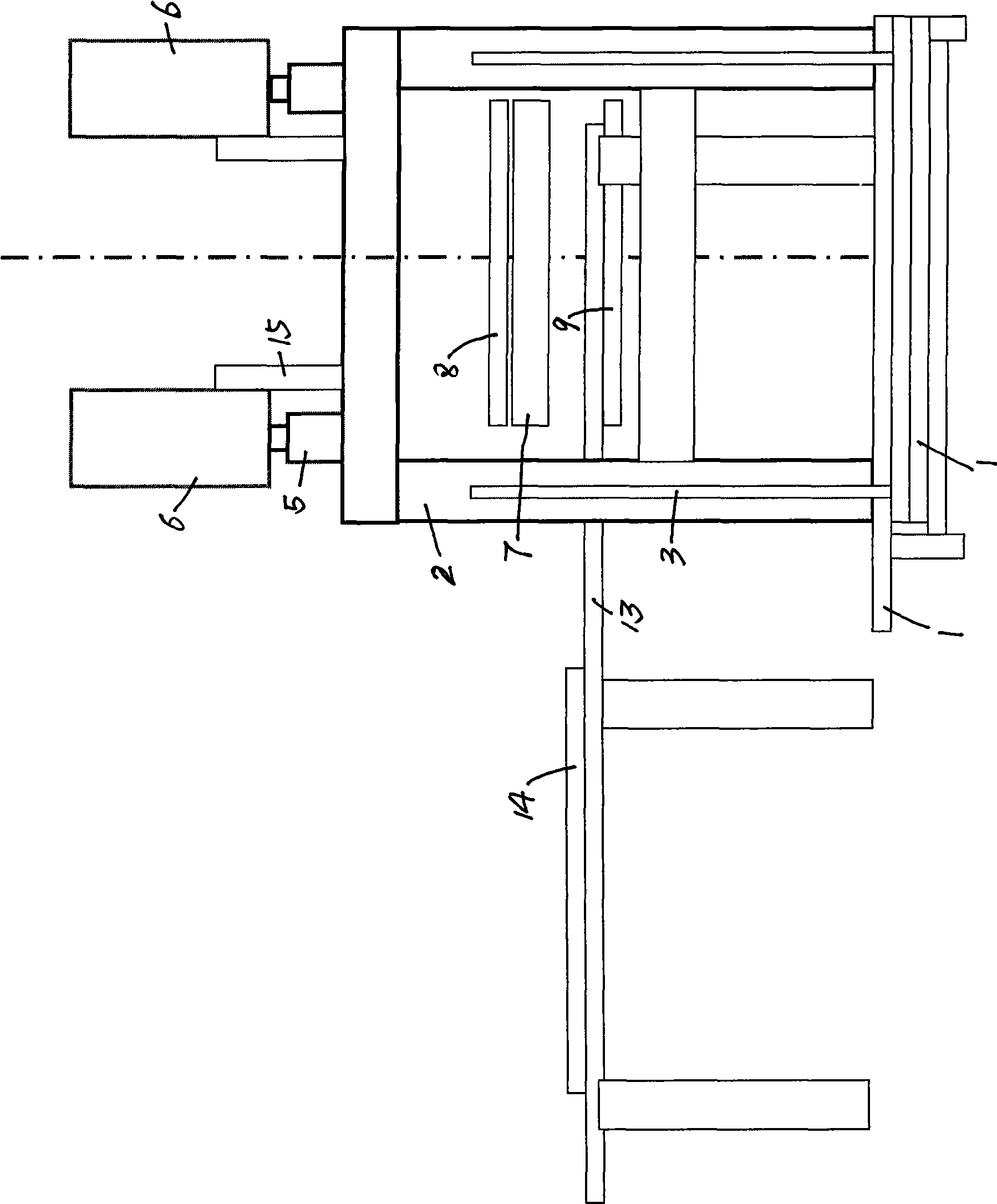

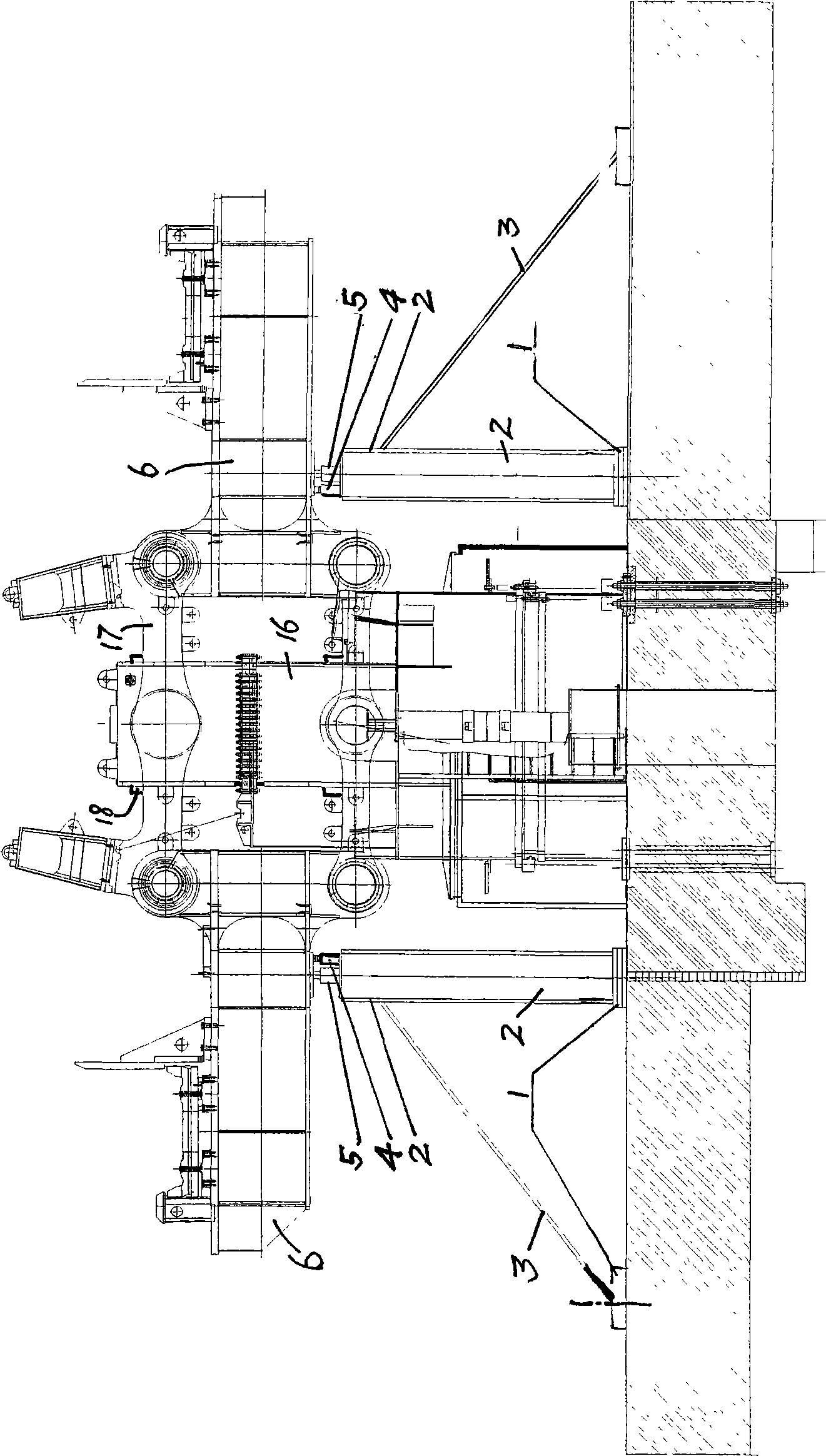

[0038] The ladle turret of Meishan No. 2 continuous casting machine is a butterfly double wishbone designed by voestalpine, with a total weight of 185t above the slewing bearing. The ladle turret is located under the track beams of the L trains on the ③-④ line of the factory building, and the hoisting position is extremely difficult. The slewing bearing of the slewing table of the large bag is replaced by the fixing bolts of the ring gear during use. The second is that there is a "snap, slap" sound when rotating with no load and load. The third is the abnormal wear of large particles in the grease. The particles reach 5mm, and some have a thickness of 2.5mm; according to the above phenomena, it is concluded that the slewing bearing is damaged and must be replaced immediately.

[0039] Prepare relevant tools and equipment:

[0040] 1. Make two supports (5050 × 1000 × 3050) with 600 × 300 I-beam in advance to erect the jack and install various protective supports. Checkered pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com