Method for quickly replacing pivotal bearing of bale panoramic tables

A technology of bale turntable and slewing bearings, which is applied in the field of rapid replacement of slewing bearings of bale turntables, can solve problems such as poor safety, difficulty in reassembly, and difficulty in leveling, and achieve high replacement quality, low construction cost, High safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

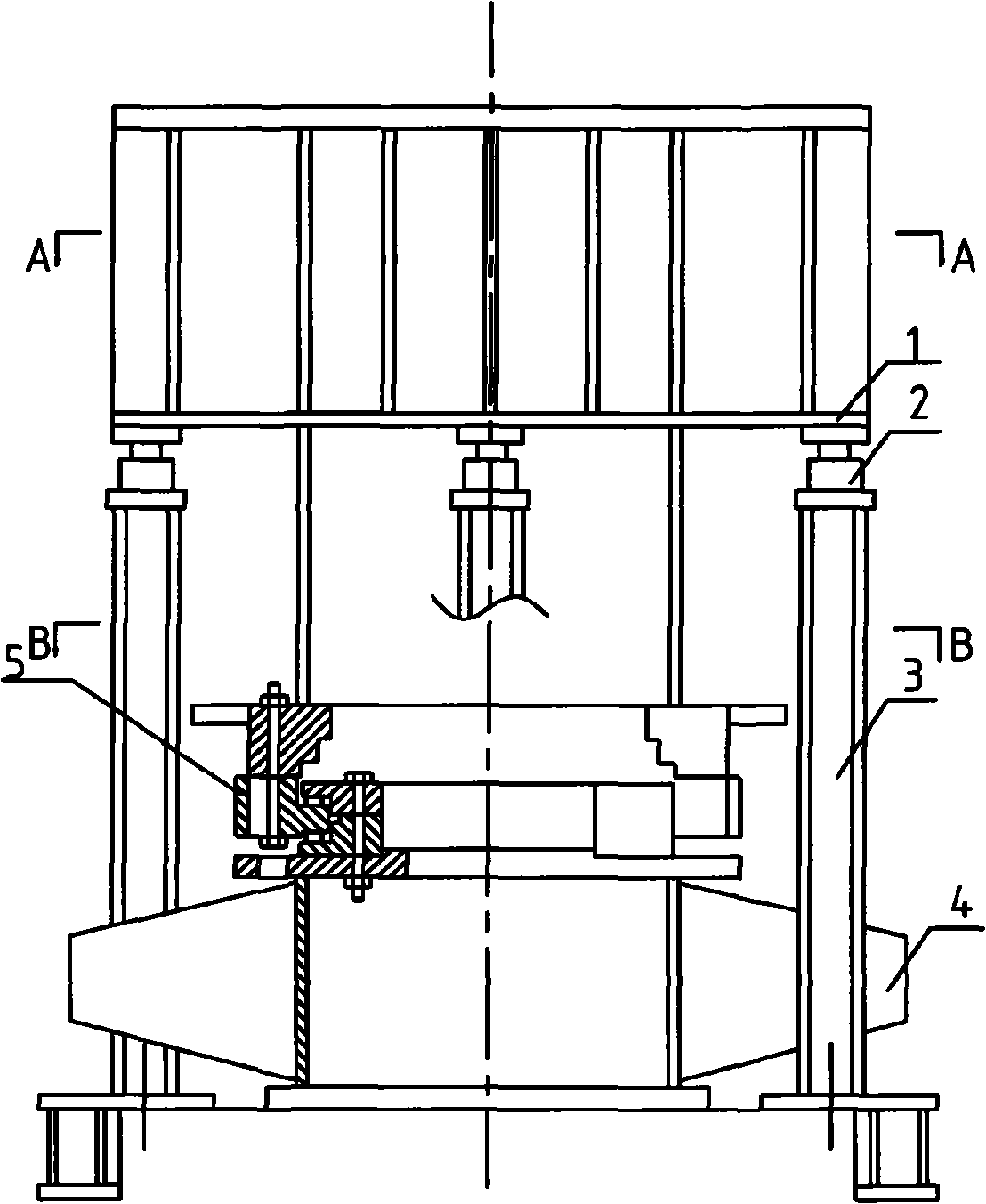

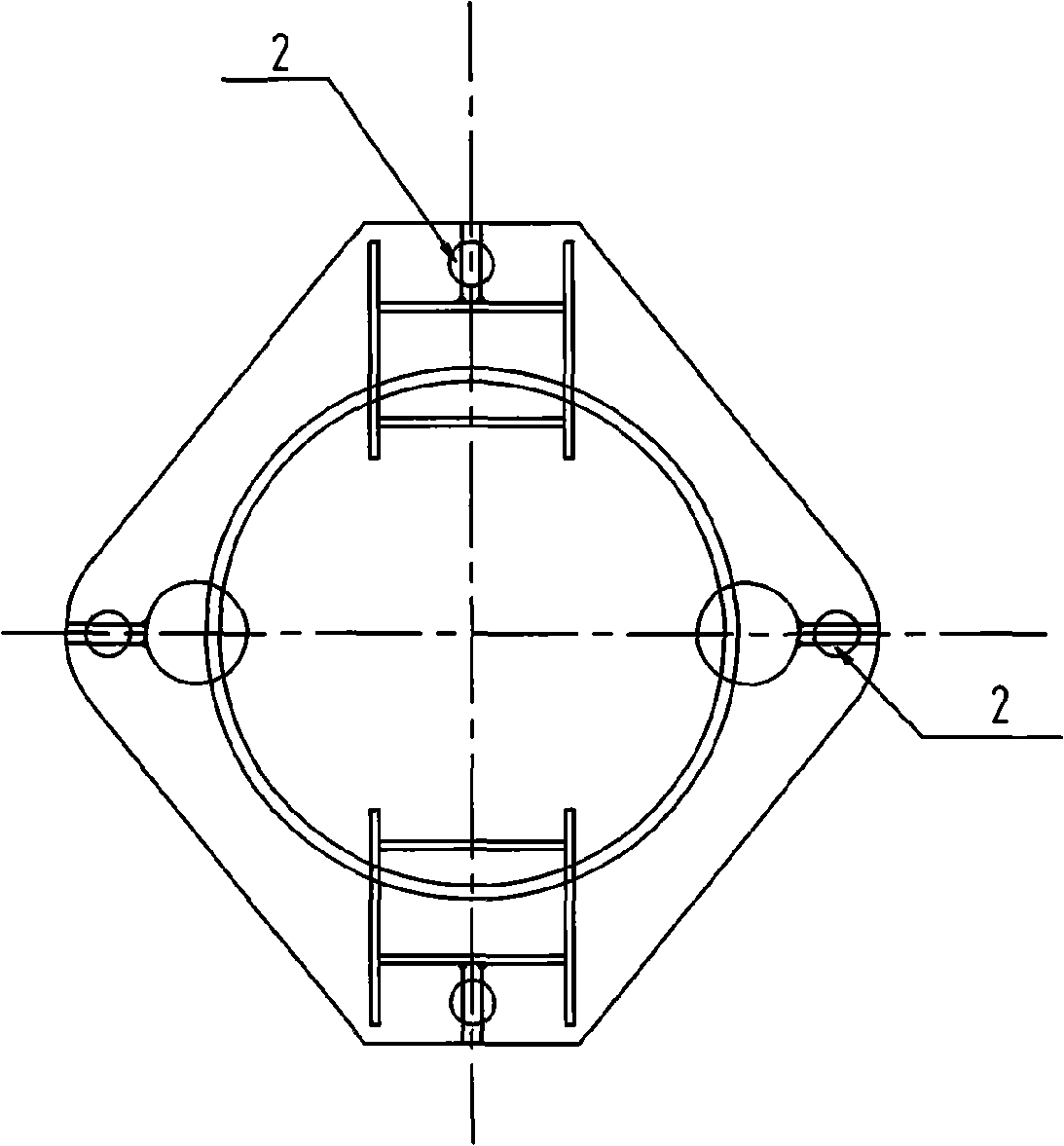

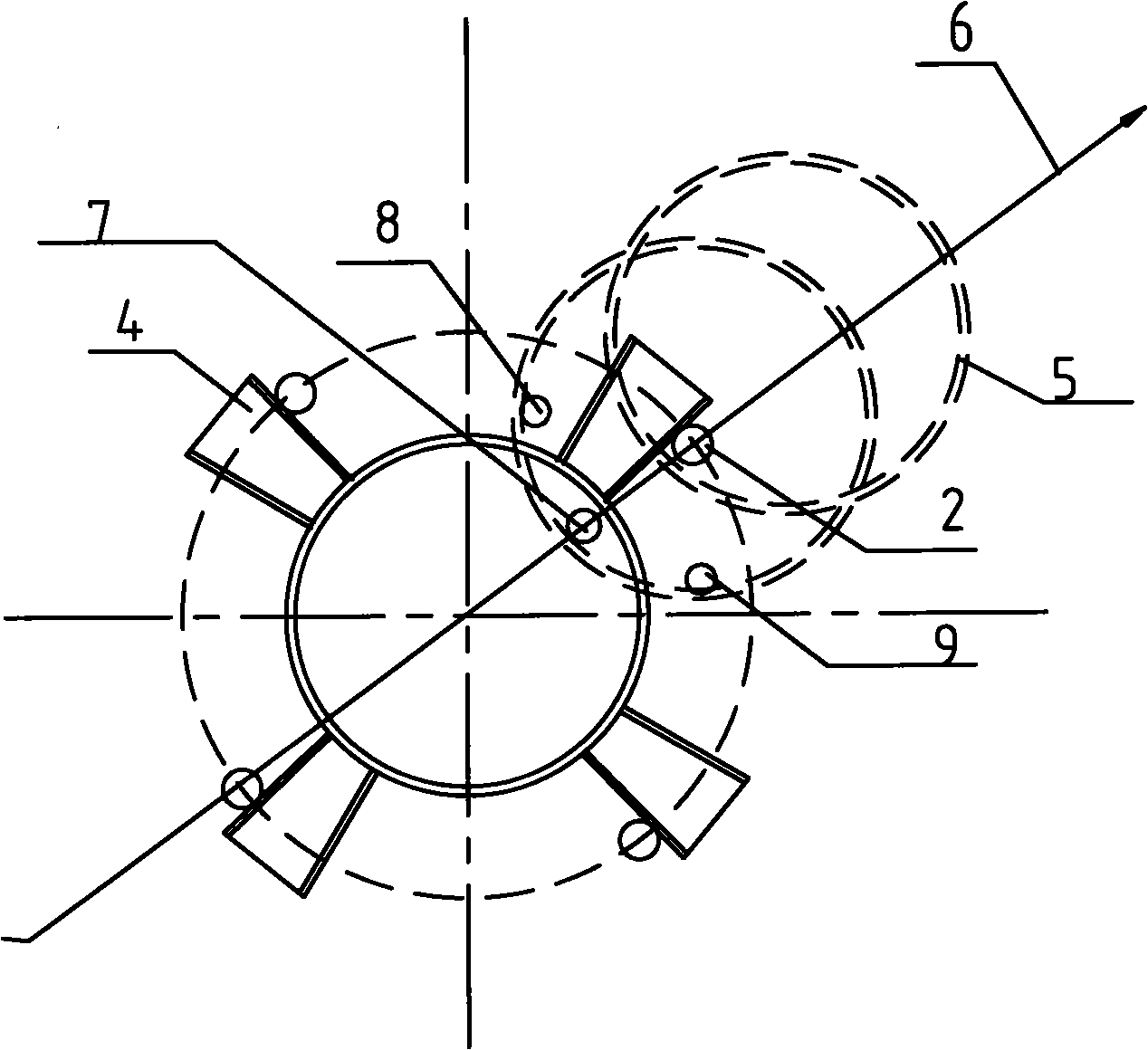

[0014] Embodiment: Referring to the accompanying drawings, the method of the present invention is used to quickly replace the slewing bearings of the ladle slewing table on the thin slab continuous casting and rolling production line of Baotou Iron and Steel Co., Ltd., and only 7 days are needed to complete the task of quickly replacing the slewing bearings. The production of the bale turntable one day in advance can produce 4,000 tons of thin plates, worth about 20 million yuan, which has good economic and social benefits. In the quick replacement process of the slewing bearing, the jacks 2, 7, 8, and 9 all use 200t jacks, and the four columns 3 use seamless steel pipes. It is necessary to ensure that the verticality of the columns is within 0.5 / 1000, and the levelness of the steel plate on the top surface of the columns is 0.05. Within mm; when the slewing bearing 5 is completely exposed on the groove of the base 10 of the bale turntable, the gap between the slewing bearing 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com