Five-axis side milling method for planar double-enveloping worm

A plane secondary enveloping, toroidal worm technology, applied in worms, elements with teeth, belts/chains/gears, etc., can solve uneven grinding allowance, reduce processing efficiency, increase process and cost, etc. problems, to improve the machining efficiency and the accuracy of the tooth surface, to avoid uneven roughing allowances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

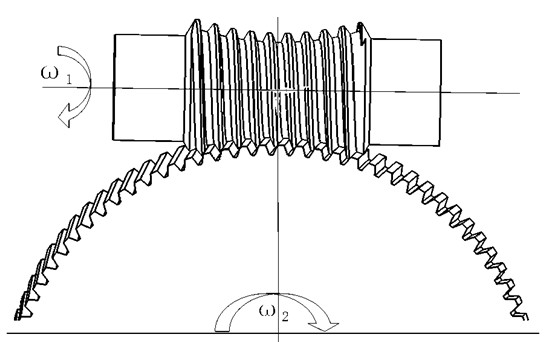

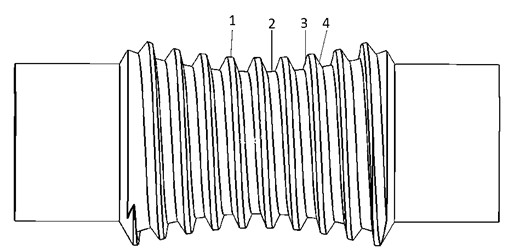

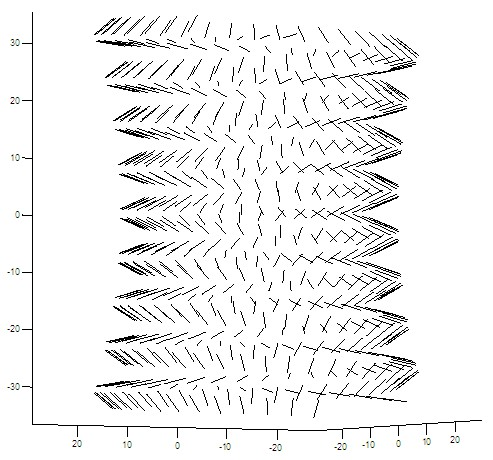

[0040] The processing steps of the five-axis side milling of the plane quadratic enveloping toroidal worm provided according to the present invention are as follows: figure 2 As shown, the planar quadratic enveloping toroidal worm can be divided into four parts: A-side tooth surface, B-side tooth surface, tooth bottom surface, and tooth top surface, among which A-side tooth surface, B-side tooth surface, and tooth bottom surface are to be processed part.

[0041] 1. Select the appropriate side milling cutter according to the material and structure of the part;

[0042] In this embodiment, the processing material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com