Two freedom degree straight line ring surface worm transmission and method for manufacturing same

A technology of a toroidal worm and a manufacturing method, which is applied to the worm, transmission, gear transmission, etc., can solve the problems of easy pitting, underutilization of tooth surfaces, poor working conditions of contact lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] specific implementation plan

[0026] Embodiments of the present invention will be described below according to the accompanying drawings.

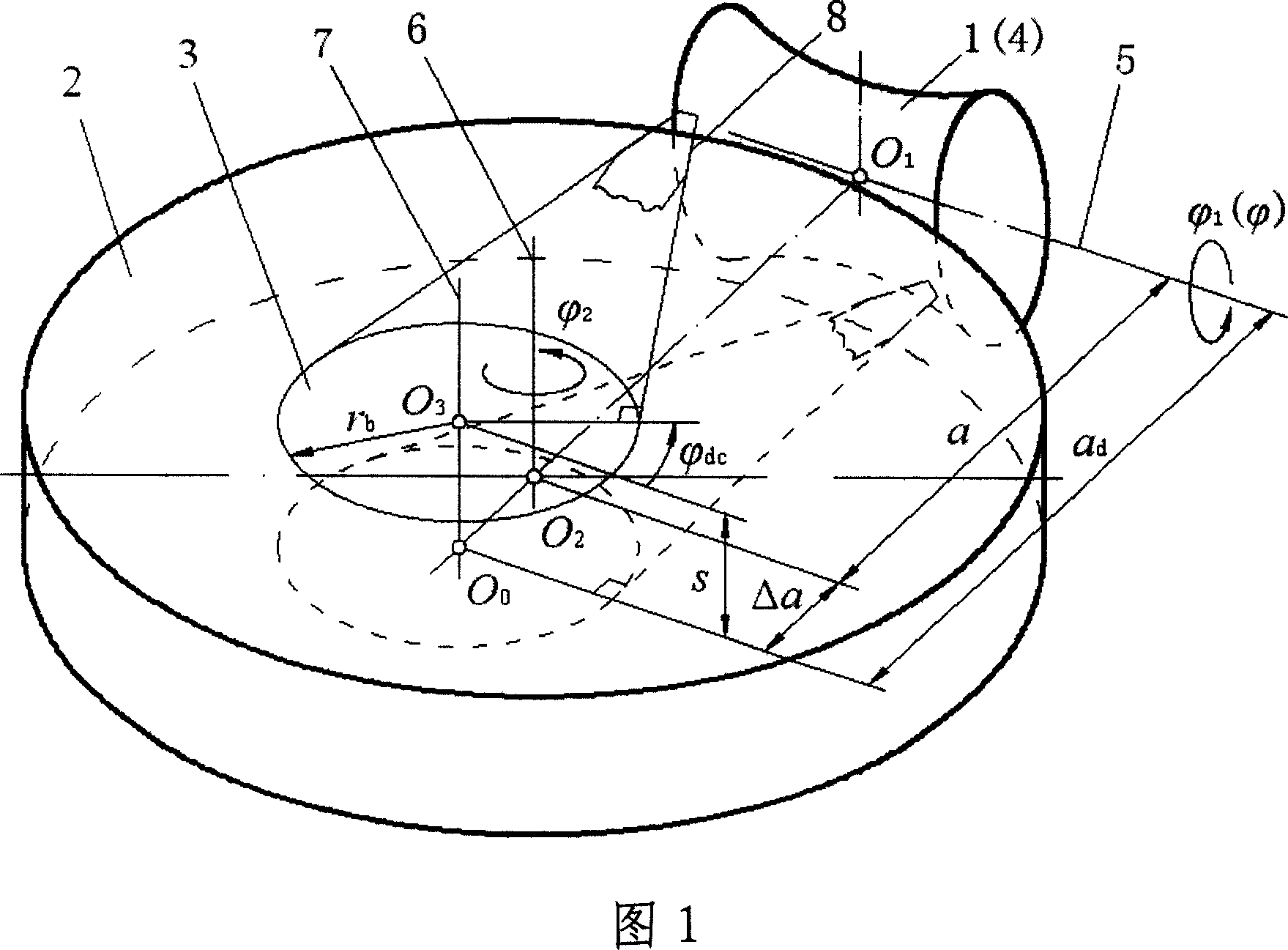

[0027] The two-degree-of-freedom linear toroidal worm machining method can be realized on a common gear hobbing machine. As shown in Figure 1, install the blank of the toroidal worm 1 on the hob holder (position 5 of the axis of the worm in Figure 1), and install the tool seat 3 on the working table of the gear hobbing machine (position 7 of the axis of the tool seat in Figure 1), and the two axes are perpendicular Staggered, center distance is a d . The corner of the blank of the toroidal worm 1 is obtained from the hob; the hob moves along the column (parallel to the tool seat axis 7), which is equivalent to the opposite direction of the tool seat 3 and the same displacement relative to the blank of the torus worm 1 The movement s; according to the transmission ratio i of the blank of the toroidal worm 1 and the tool seat 3l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com