High-uniformity shallow junction diffusion process in low-pressure environment

A low-pressure environment, diffusion process technology, applied in the field of solar cells, can solve the problems of single-chip and whole tube non-uniformity control range, inability to real-time diffusion depth, small square resistance control range, etc., to reduce local poor sintering and facilitate sintering. process, the effect of reducing unit energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

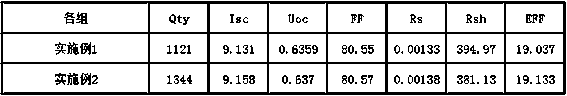

Embodiment 1

[0020] Cell diffusion is carried out according to the following process:

[0021] Unified collection of silicon wafers after traditional acid texturing;

[0022] Lead the silicon wafer into the special quartz boat for low-pressure process;

[0023] Purify the furnace tube, the time is 20s, the temperature is 780°C, the pressure of the furnace body is normal pressure, the gas medium is nitrogen, and the maximum nitrogen mass flow rate is 3000SCCM;

[0024] Entering the boat, the time is 1000s, the temperature is 780°C, the pressure of the furnace body is normal pressure, the gas medium is nitrogen, and the maximum nitrogen mass flow rate is 3000SCCM;

[0025] Constant temperature diffusion, time 400s, temperature 780°C, furnace body pressure is normal pressure, gas medium is oxygen and nitrogen, mass flow rate of oxygen is 500SCCM, large nitrogen is 500SCCM, open the source pipeline, source bottle pressure is 500mba, small nitrogen is 800SCCM.

[0026] Constant temperature de...

Embodiment 2

[0037] Cell diffusion is carried out according to the following process:

[0038] Unified collection of silicon wafers after traditional acid texturing;

[0039] Lead the silicon wafer into the special quartz boat for low-pressure process;

[0040] Purify the furnace tube, the time is 20s, the temperature is 780°C, the pressure of the furnace body is normal pressure, the gas medium is nitrogen, and the maximum nitrogen mass flow rate is 3000SCCM;

[0041] Entering the boat, the time is 1000s, the temperature is 780°C, the pressure of the furnace body is normal pressure, the gas medium is nitrogen, and the maximum nitrogen mass flow rate is 3000SCCM;

[0042] The main vacuuming time is 240s, the temperature is 780°C, and the furnace body pressure is 50mbar;

[0043] Leak detection, time 60s, temperature 780°C, furnace pressure 50mbar;

[0044] Vacuuming, time 40s, temperature 780°C, furnace pressure 50mbar;

[0045] Constant temperature diffusion, time 400s, temperature 780...

Embodiment 3

[0066] Cell diffusion is carried out according to the following process:

[0067] Unified collection of silicon wafers after traditional acid texturing;

[0068] Lead the silicon wafer into the special quartz boat for low-pressure process;

[0069] Purify the furnace tube, the time is 20s, the temperature is 780°C, the pressure of the furnace body is normal pressure, the gas medium is nitrogen, and the maximum nitrogen mass flow rate is 3000SCCM;

[0070] Entering the boat, the time is 1000s, the temperature is 780°C, the pressure of the furnace body is normal pressure, the gas medium is nitrogen, and the maximum nitrogen mass flow rate is 3000SCCM;

[0071] The main vacuuming time is 240s, the temperature is 780°C, and the furnace body pressure is 100mbar;

[0072] Leak detection, time 60s, temperature 780°C, furnace pressure 100mbar;

[0073] Vacuuming, time 40s, temperature 780°C, furnace pressure 100mbar;

[0074] Constant temperature diffusion, time 400s, temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com