Multi-start worm milling machine

A multi-head worm and milling machine technology, applied in the direction of worms, gear teeth, gear cutting machines, etc., can solve the problems of low indexing accuracy, low processing pass rate, and inability to process, so as to achieve improved indexing accuracy, high transmission accuracy, and indexing accuracy. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present technology will be further described below through embodiments in conjunction with the accompanying drawings.

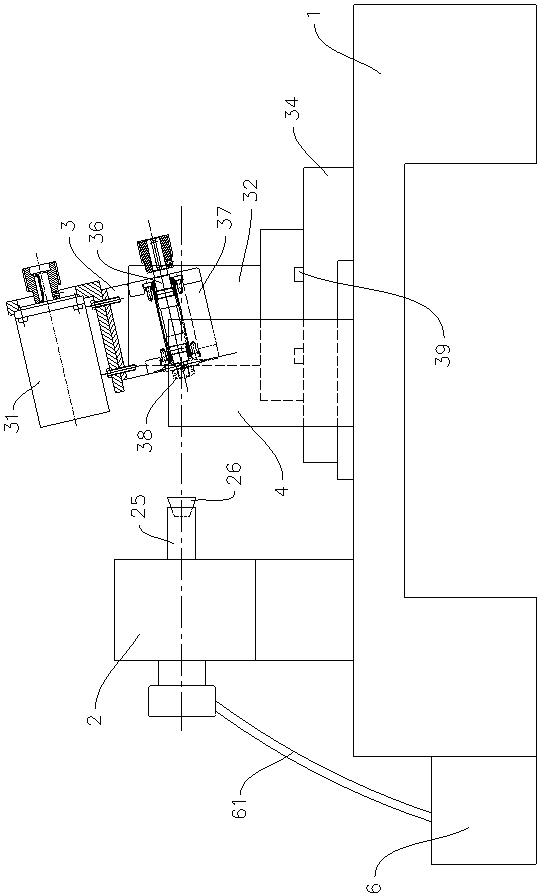

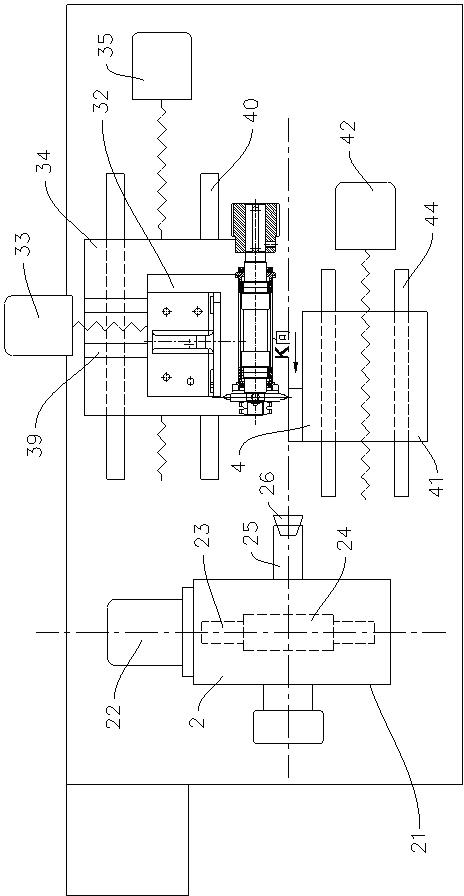

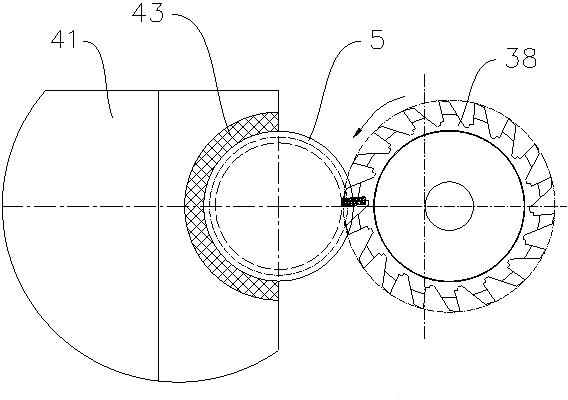

[0017] The multi-head worm milling machine includes a machine base 1, a headstock 2 for driving the machined worm to rotate, a cyclone milling head 3 including a milling cutter, and a tailstock device 4 for milling the machined worm.

[0018] The main shaft box 2 includes a box body 21 , a main servo motor 22 , a main worm 23 , a main turbine 24 that cooperates with the main worm 23 , a main shaft 25 , and the like. The output shaft of the main servo motor is connected with the main worm, and the main turbine shaft 26 is connected with the main shaft. The rotation of the main servo motor 22 drives the main worm 23 to rotate, and the main turbine 24 drives the main shaft 25 to rotate. An elastic jacket 26 is provided on the main shaft 25, and the elastic jacket is powered by an oil cylinder for clamping the head end of the worm.

[0019] The tails...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com