Composite working machine tool and working method in composite working machine tool

A composite machining and machine tool technology, applied in metal processing machinery parts, metal processing equipment, lathes, etc., can solve the problems of increased processing costs, complex tools, and difficulty in arbitrarily setting groove width, groove radius, and groove cross-sectional shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

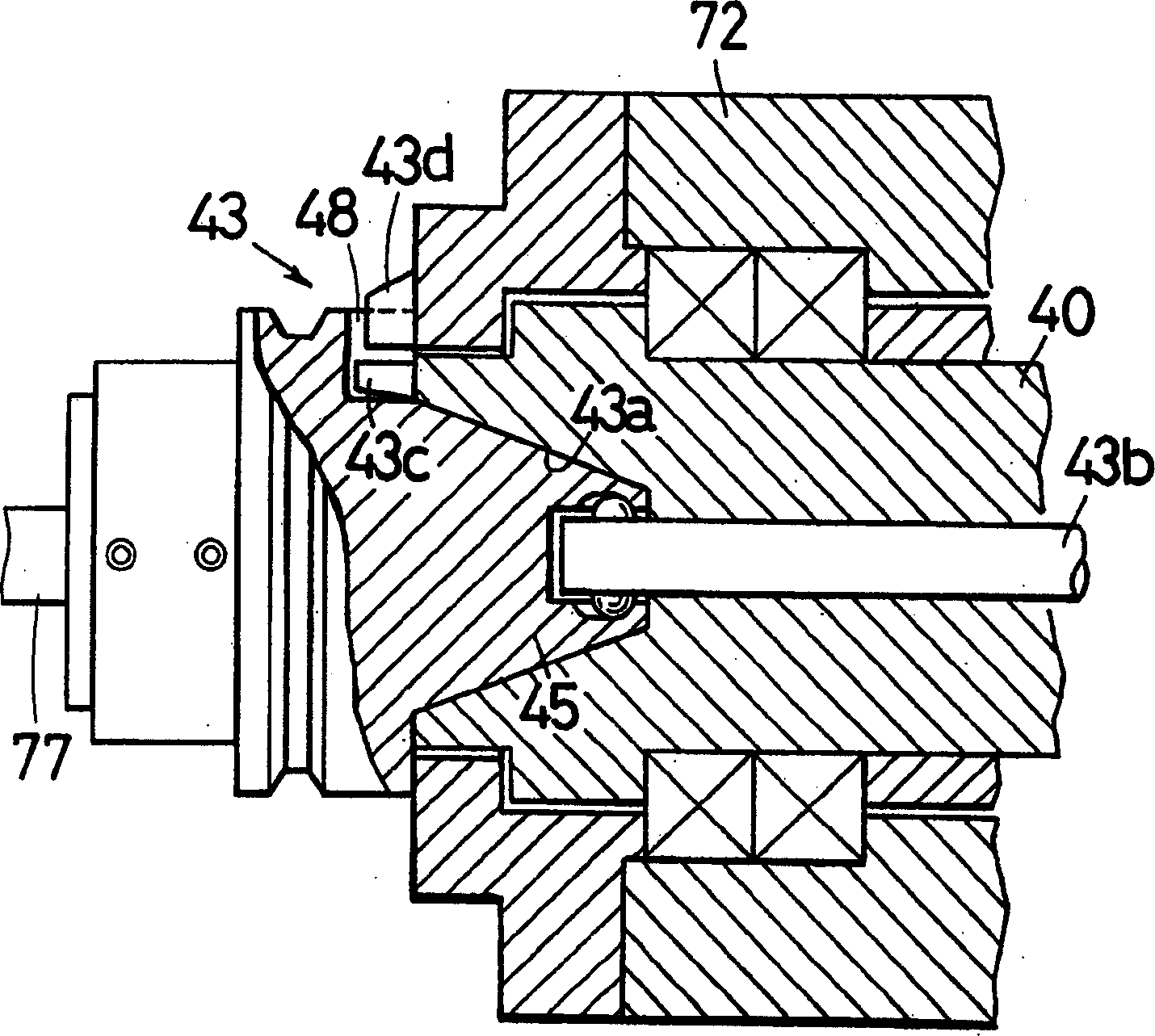

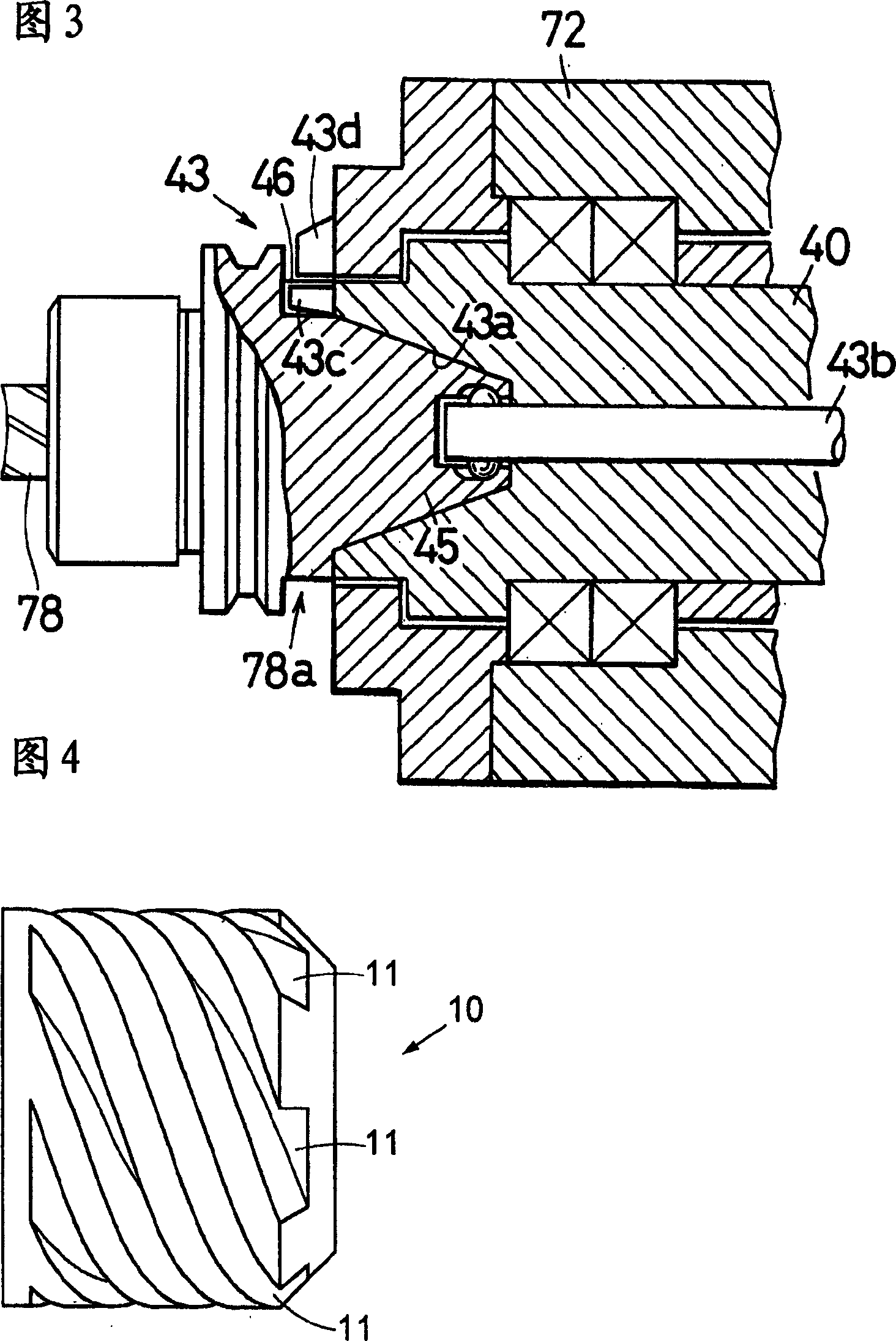

Embodiment Construction

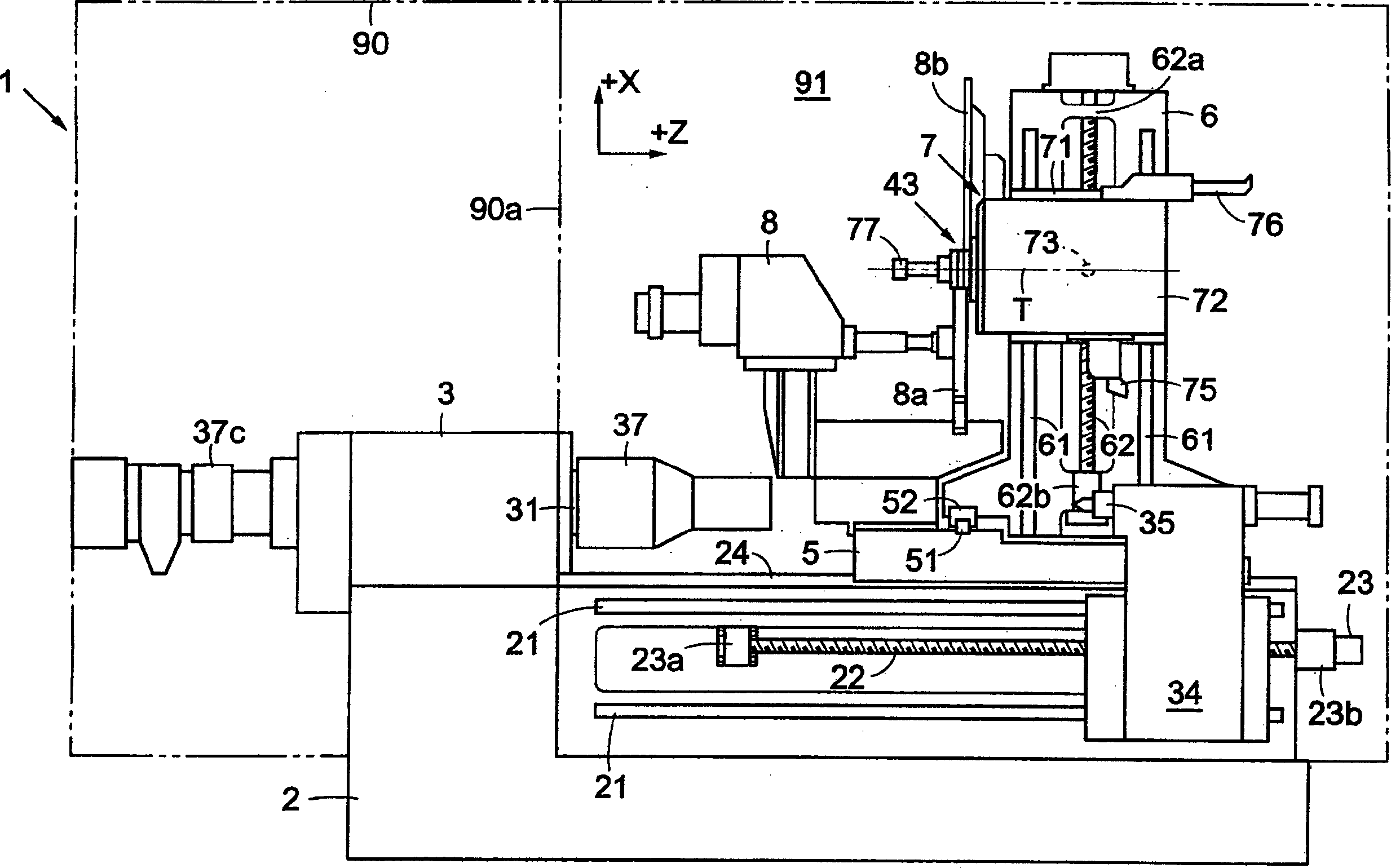

[0039] Embodiments of the present invention will be described with reference to the drawings. figure 1It is a figure which shows the whole structure of the compound processing machine tool 1 of this invention. A headstock 3 is fixedly arranged on a bed 2 serving as a base of the multi-function machine tool 1 . On the headstock 3, a spindle 31 for rotatably driving a workpiece is rotatably provided. The main shaft 31 is arranged such that its center axis becomes a horizontal direction, and the direction of the center axis is taken as the Z-axis direction of the Cartesian coordinate system.

[0040] Also, on the top end of the main shaft 31, a workpiece mounting mechanism 37 for mounting a workpiece is fixed. The spindle 31 is rotationally driven by a built-in spindle motor (not shown) in a state where a workpiece is mounted on the workpiece mounting mechanism 37 . In addition, the NC device (not shown) for controlling the rotary motion of the main shaft 31 has a function of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com