Toroid worm numerical control machine capable of making up center distance

A toroidal worm, CNC machine tool technology, applied in the direction of worm, mechanical equipment, components with teeth, etc., can solve the problems of uneconomical, large vertical and horizontal dimensions of the machine tool, unable to meet the center distance, etc., and achieves small occupied space, Strong versatility and the effect of promoting promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

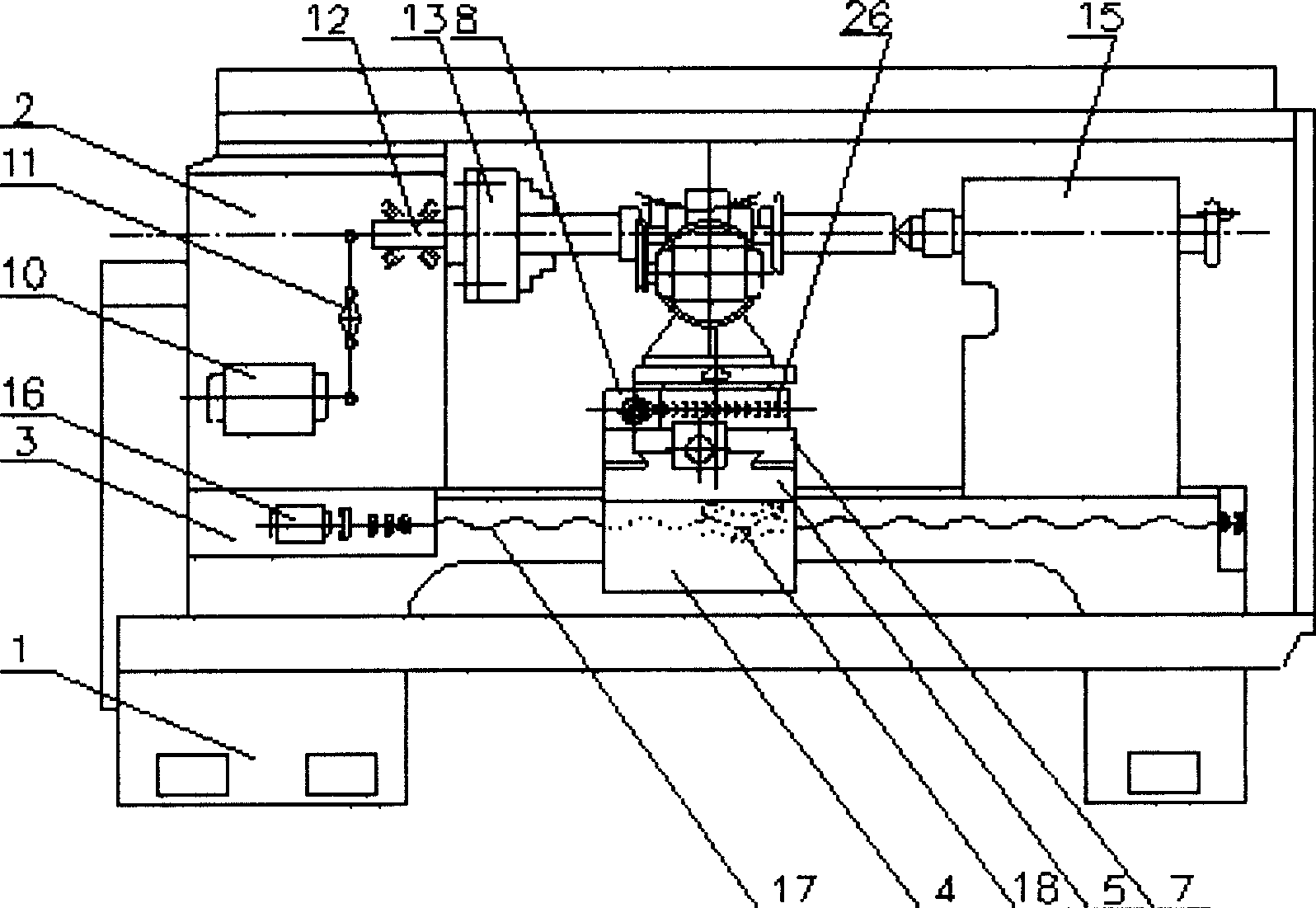

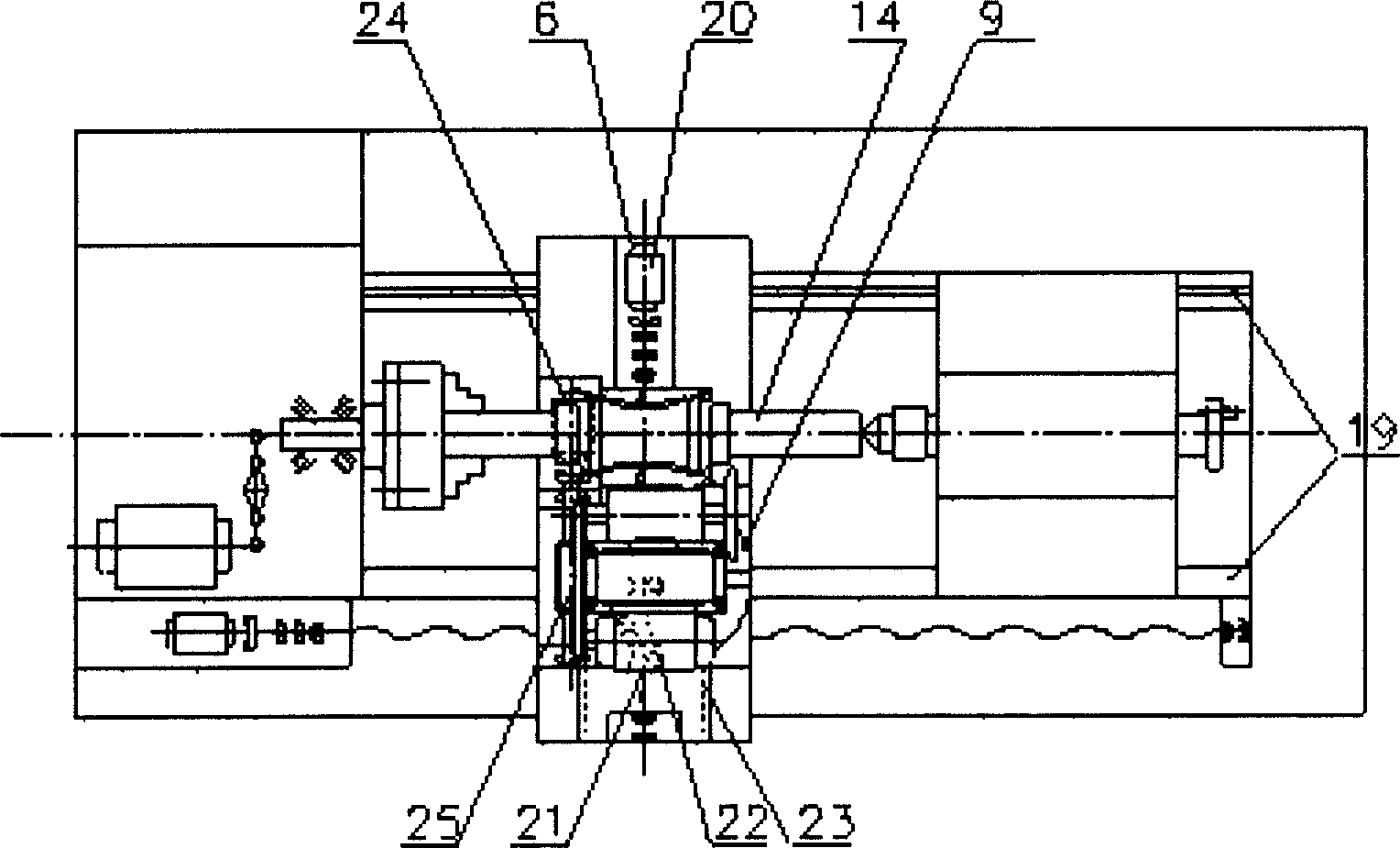

[0022] The working principle and implementation modes of the present invention will be further described below in conjunction with the accompanying drawings:

[0023] In the present invention, the positional relationship of the four axes X, Y, Z, and A is defined as follows: X and Z are two mutually perpendicular moving axes in the horizontal plane, A is the rotation axis (main axis) parallel to Z, and Y is The axis of rotation perpendicular to the XZ plane; the four axes can be controlled by single action or linked in any combination.

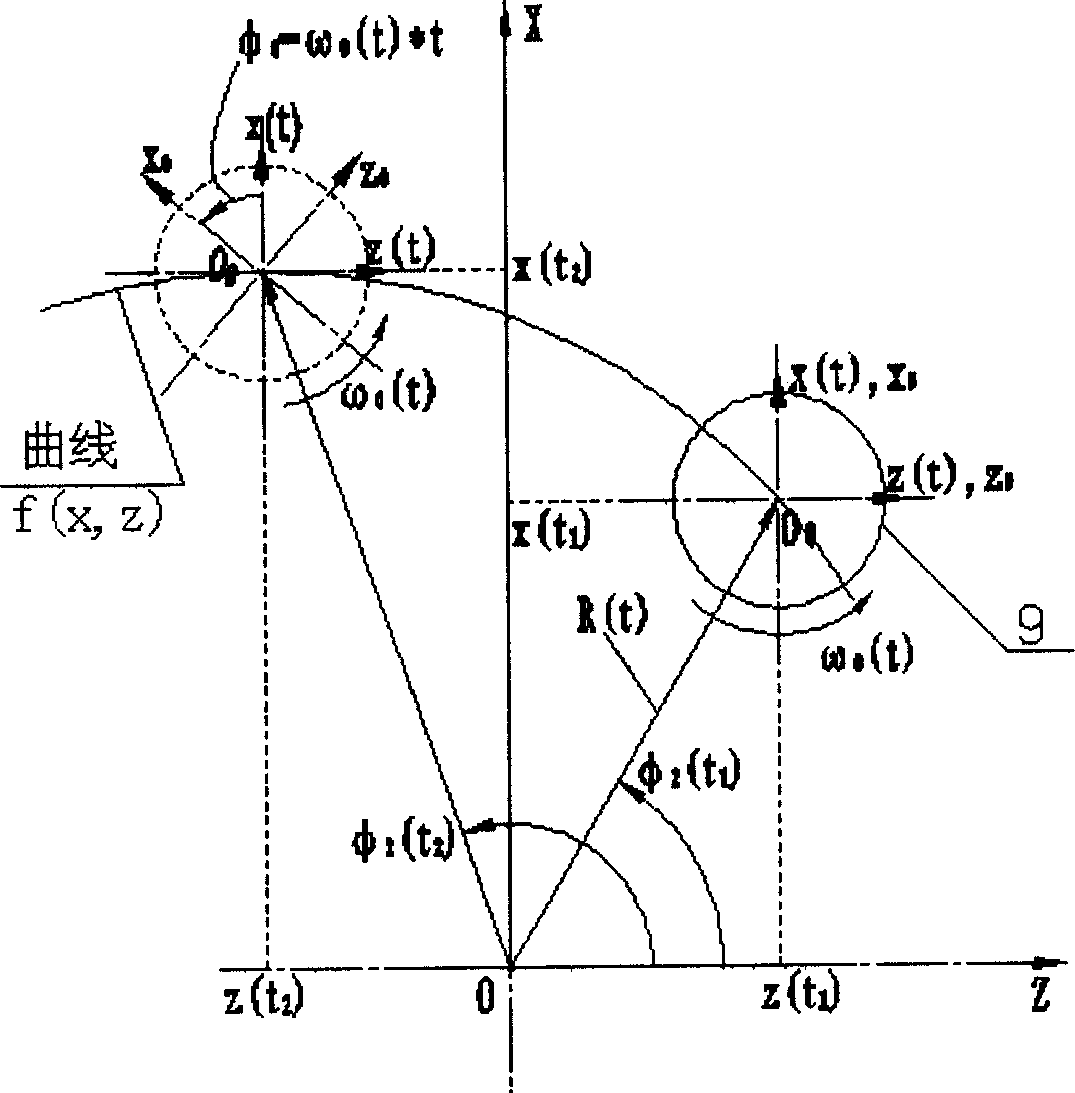

[0024] 1) When the four axes of A, X, Y, and Z are linked, the machine tool can be used to process concave and convex toroidal worms; it is also suitable for processing complex rotating surface parts. image 3 As shown, when the rotation center of the tool table makes a circular motion according to a virtual center O as the center of the circle, that is, f(x, z) is a circular arc, which satisfies X 2 +Z 2 -R 2 =0, and the movement of any curve (in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com