Double-sided precision grinding method and equipment for enveloping toroidal worm tooth surface

A technology of worm tooth surface and enveloping ring, applied in the direction of worm, mechanical equipment, components with teeth, etc., can solve the problems of irreversible recovery, poor conjugation between worm gear and worm, increasing operating hours and labor intensity, etc. Interchangeability, improve worm gear tooth surface accuracy and transmission pair accuracy, reduce operating hours and labor intensity and the effect of rejection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

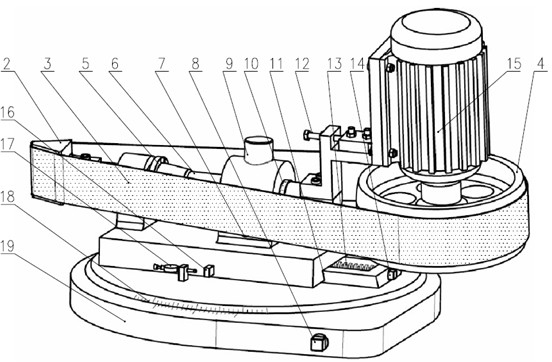

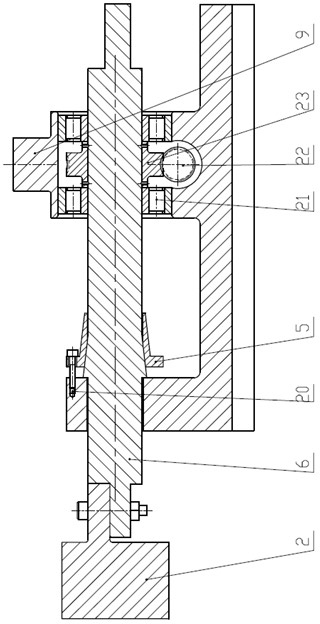

[0043] The implementation process of the present invention for grinding a plane enveloping toroidal worm and its worm gear hob on a gear hobbing machine will be further described below in conjunction with the accompanying drawings, but the present invention is not limited thereto.

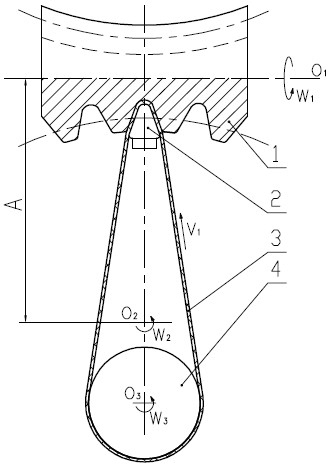

[0044] In the embodiment, the grinding method of the plane enveloping toroidal worm tooth surface and its worm wheel hob is based on the profiling method and the enveloping generating grinding principle to realize the double-sided precise grinding of the enveloping toroidal worm tooth surface, The steps are:

[0045] 1) Accurately design and process the pressing module 2 according to the parameters of the plane-enveloping toroidal worm;

[0046] 2) Adjust the height of the tool holder of the hobbing machine according to the height from the bottom surface of the grinding head to the center line of the main shaft of the abrasive belt grinding head, clamp the plane enveloping toroidal worm 1 on the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com