Numerical control five-axle linkage planar double enveloping worm cyclone cutting machine tool

A toroidal worm, cutting machine tool technology, applied in worm, drive, mechanical equipment and other directions, can solve the problems of low production efficiency, high processing cost, difficult to guarantee processing accuracy, etc., to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below with reference to the accompanying drawings and embodiments.

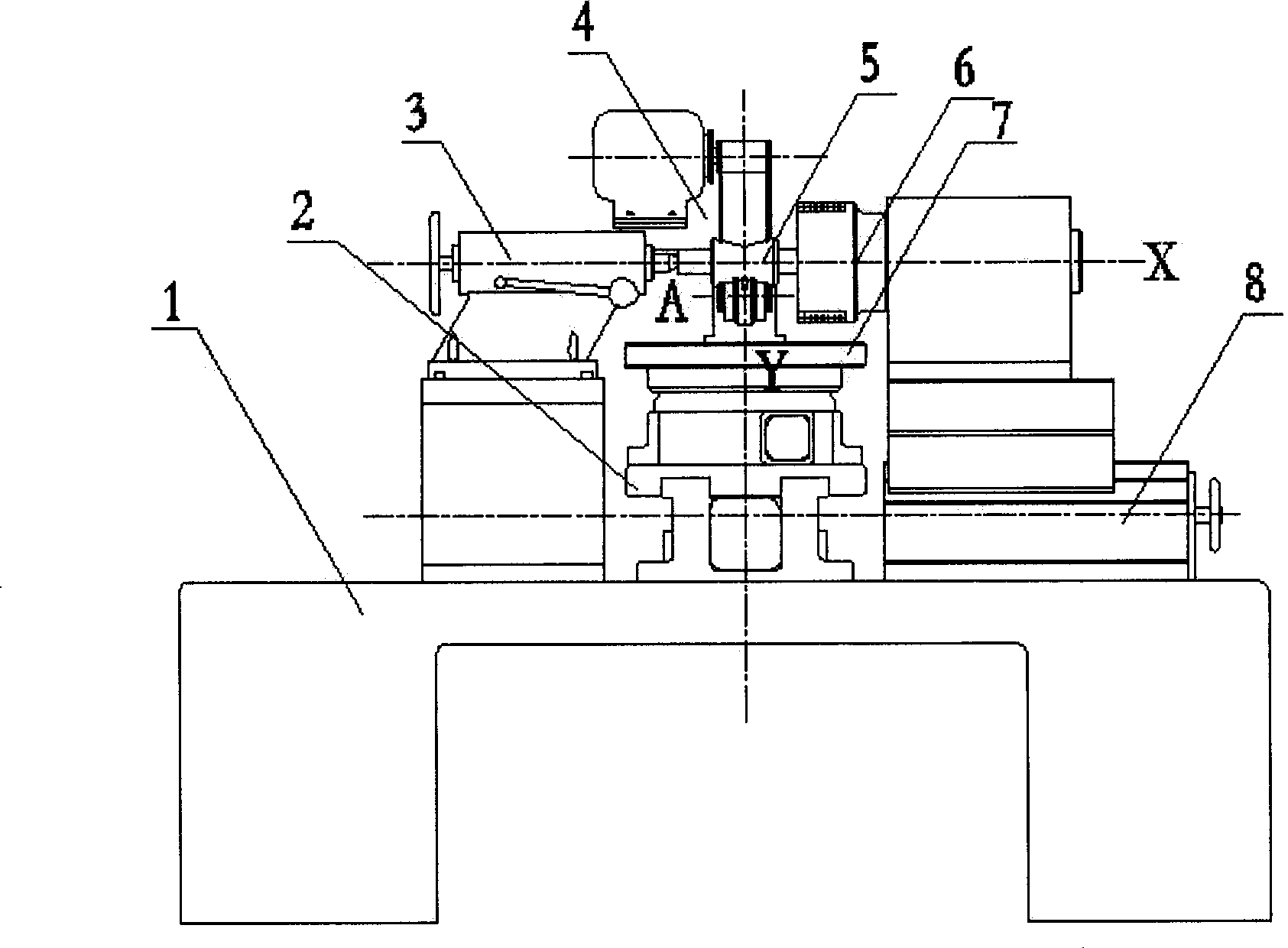

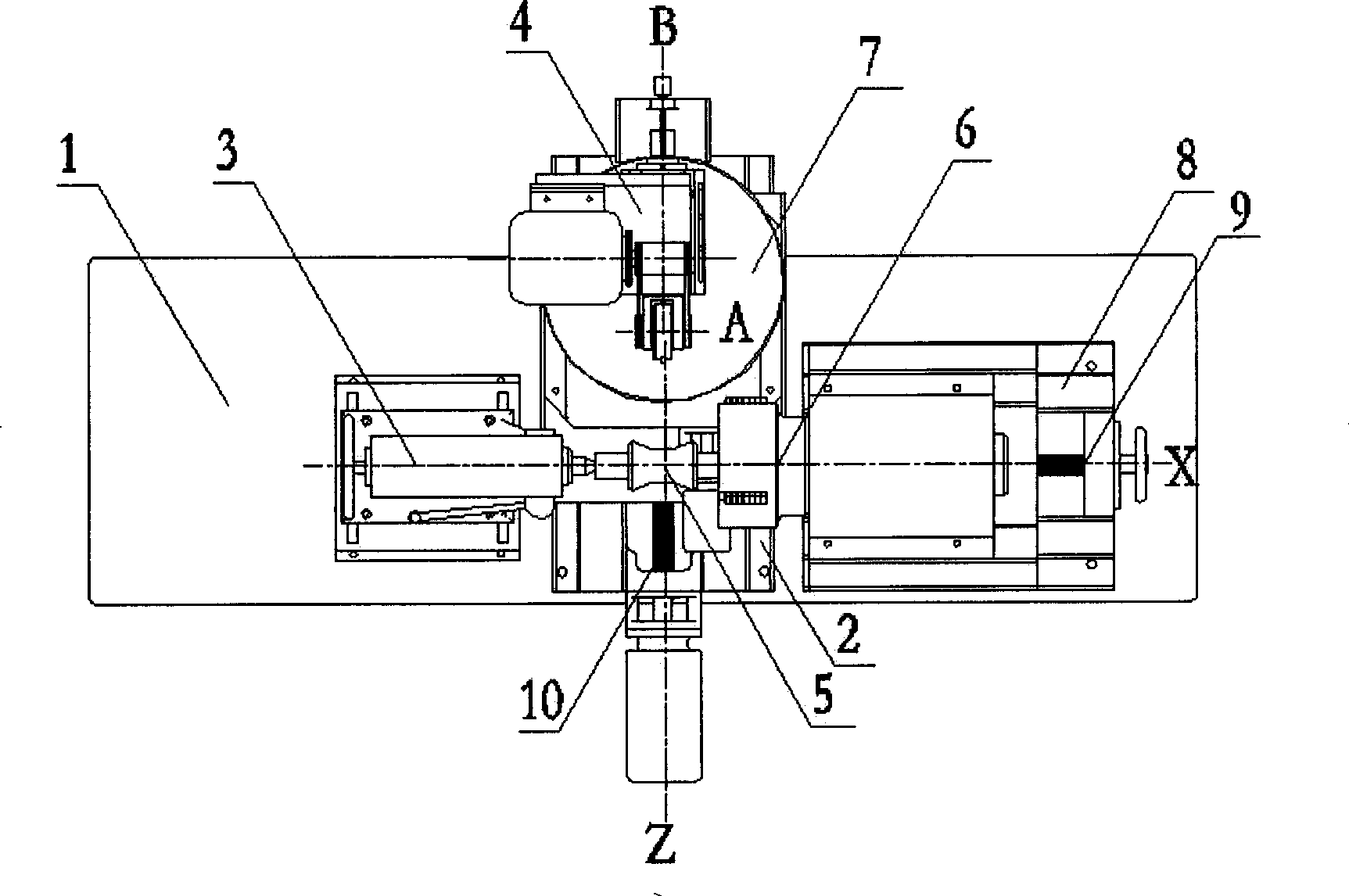

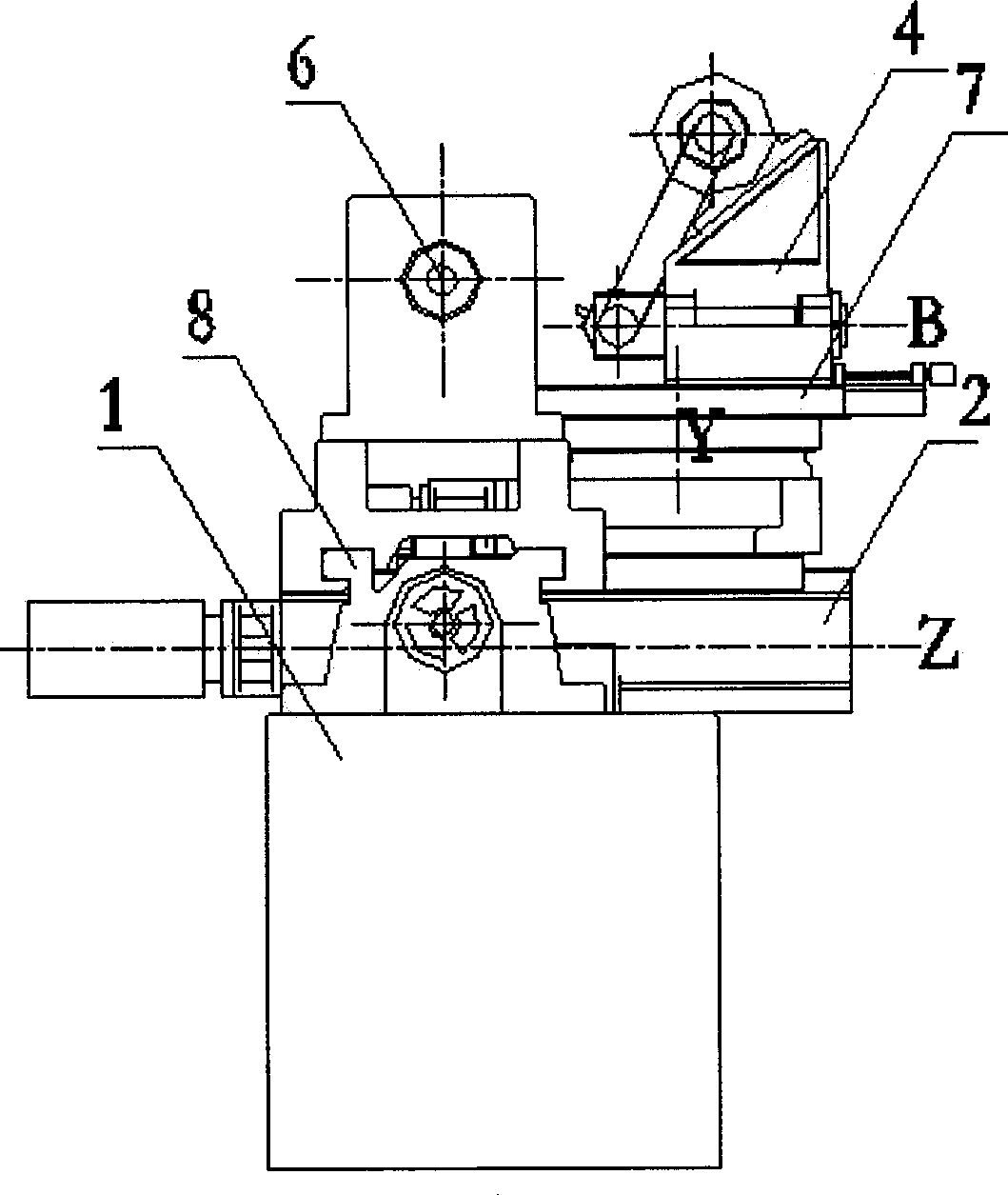

[0019] Such as figure 1 , 2 , 3, 4, and 5, the CNC five-axis three-linkage plane enveloping toroidal worm cyclone cutting machine tool of the present invention mainly includes a bed 1, a horizontal carriage 2, a tailstock 3, a main shaft 6 and a longitudinal carriage 8, and the transverse A rotary disc 7 that can freely rotate around the Y axis is installed on the carriage 2, and a whirlwind knife holder 4 is installed on the rotary disc 7; a cutter head 12 is installed on the whirlwind knife holder 4; two cutting knives 11 are symmetrically installed on the cutter head, But the cutter quantity is not limited to two. The cutter 11 on the cutter head 12 is installed in a plane perpendicular to the axis A of the cutter head rotation.

[0020] The numerical control system controls the rotation of the cutter head 12 around the A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com