Method for processing helical surface of toroidal worm by numerically controlled lathe

A technology of CNC lathes and toroidal worms, applied in worms, components with teeth, belts/chains/gears, etc., can solve the problem of high professional requirements for tool sharpening, not arc thread tooth surface, worm tooth pitch accumulation error Increase and other problems to achieve the effect of simplifying the control method of the machine tool, ensuring the accuracy of the tooth surface, and stabilizing the numerical control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

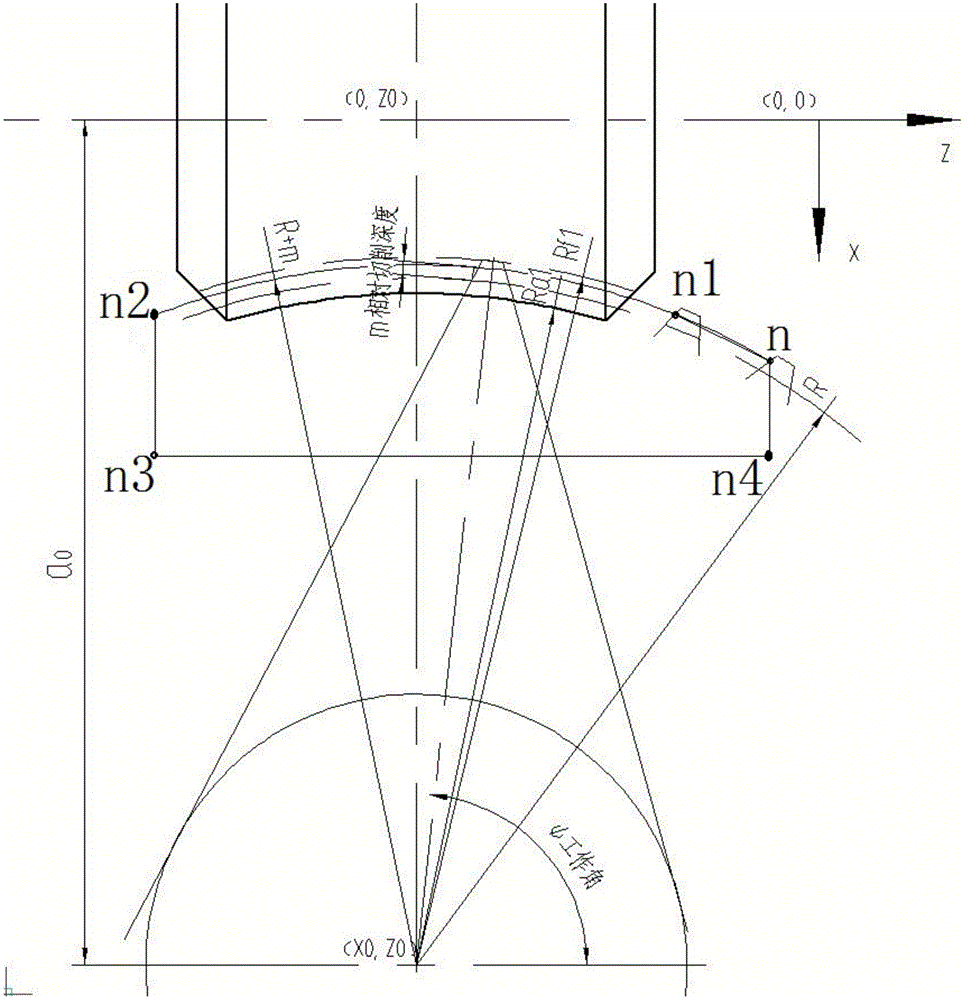

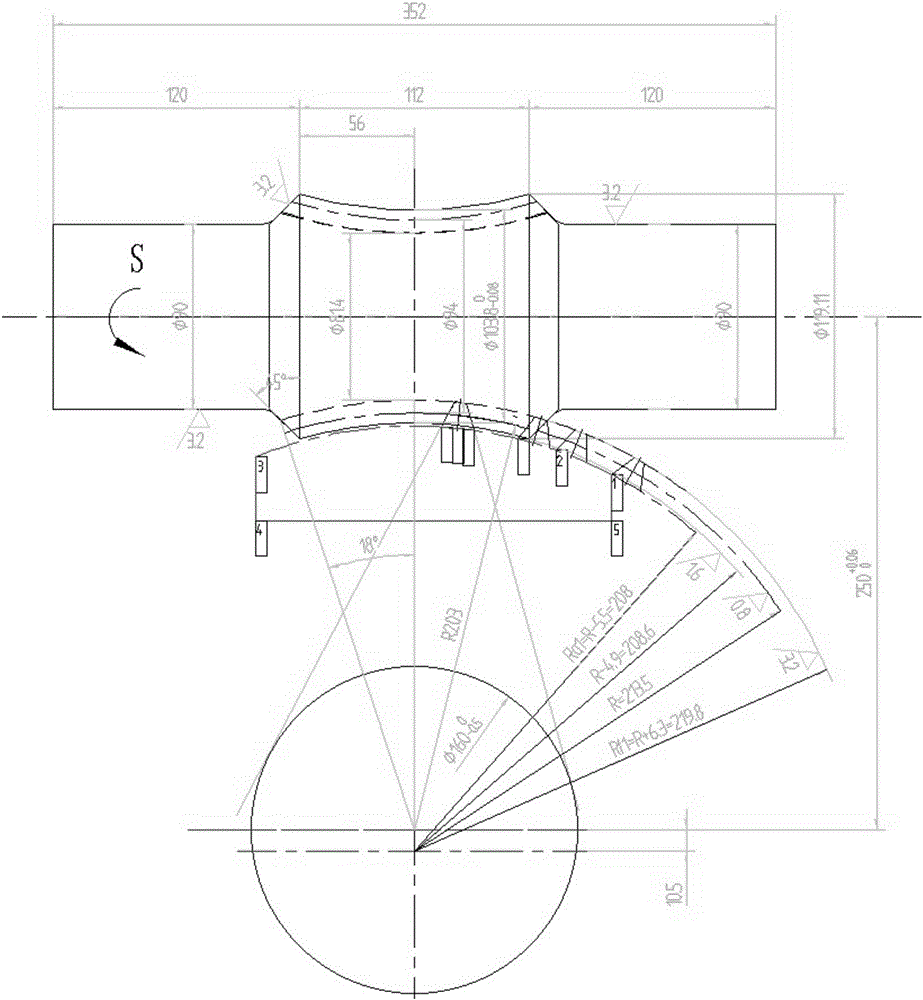

[0048] Example 1: The standard center distance of the worm is 250, the added amount of the center distance is 10.5, the number of worm heads is 2, the arc radius of the worm tooth root Rf1=219.8, the arc radius of the worm tooth top Ra1=208.6, the length of the working part of the worm is 112, and the matching standard The number of worm gear teeth is 58, the radius of the worm gear index circle is 203, the radius of the base circle is 80, the axial tooth thickness of the worm index circle is 10.38, and the right-handed plane quadratic enveloping toroidal worm with a grinding allowance of 0.3 is taken as an example.

[0049] Preparation:

[0050] [1] Measured by CAD drawing, the minimum width of the alveolar bottom is 5.90, and the maximum depth of the alveolar is 11.50. A cemented carbide cutting knife with a main cutting edge width of 5 and a maximum cutting depth of 22 is selected.

[0051] [2] The modification angle of the clamping surface of the cutter body is selected a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com