Adjustable multi-gap gear-connecting rod mechanism dynamics experiment simulation system

A technology of experimental simulation and linkage mechanism, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problem of less experimental research on the clearance of moving pairs, and achieve saving of experimental costs and simple design and processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

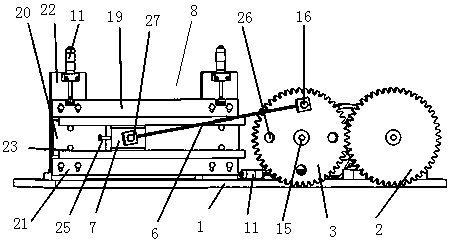

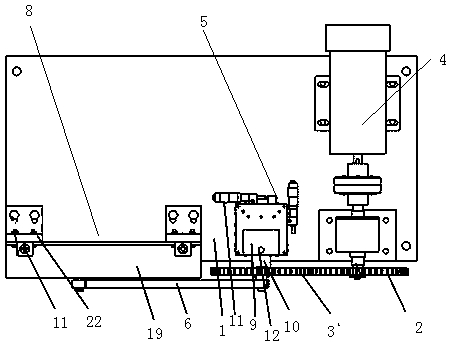

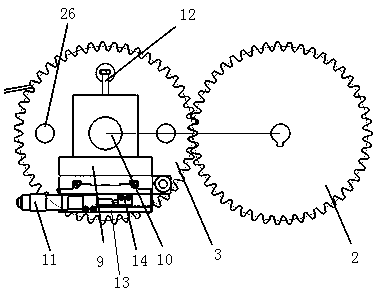

[0022] Below in conjunction with accompanying drawing, the present invention is further described:

[0023]As shown in the accompanying drawings, an adjustable multi-gap gear-link mechanism dynamics experiment simulation system is provided with a base 1, which is characterized in that a gear-rotor assembly and a crank slider assembly are arranged above the base 1. The gear rotor assembly is composed of a driving gear 2, a driven gear 3, a driving motor 4, and a driven gear fine-tuning platform 5. The driving motor 4 is arranged above the base 1 and is fixedly connected with the base 1. The driving The output shaft of the motor 4 is connected with the driving gear 2, and the side of the driving gear 2 is provided with a driven gear 3 meshed with the driving gear 2, and the driven gear 3 is fixed on the base 1 through the driven gear fine-tuning platform 5 Above, the front, rear, left, and right displacements of the driven gear 3 are adjusted through the driven gear fine-tuning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com