Telescopic safety baffle structure for elevator shaft

A safety baffle and retractable technology, which is applied in the direction of building structure, construction, and building material processing, can solve the problems of inconvenient recycling and small application range of elevator shaft safety baffles, and achieve the benefits of recycling, Improve the scope of application and reduce the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

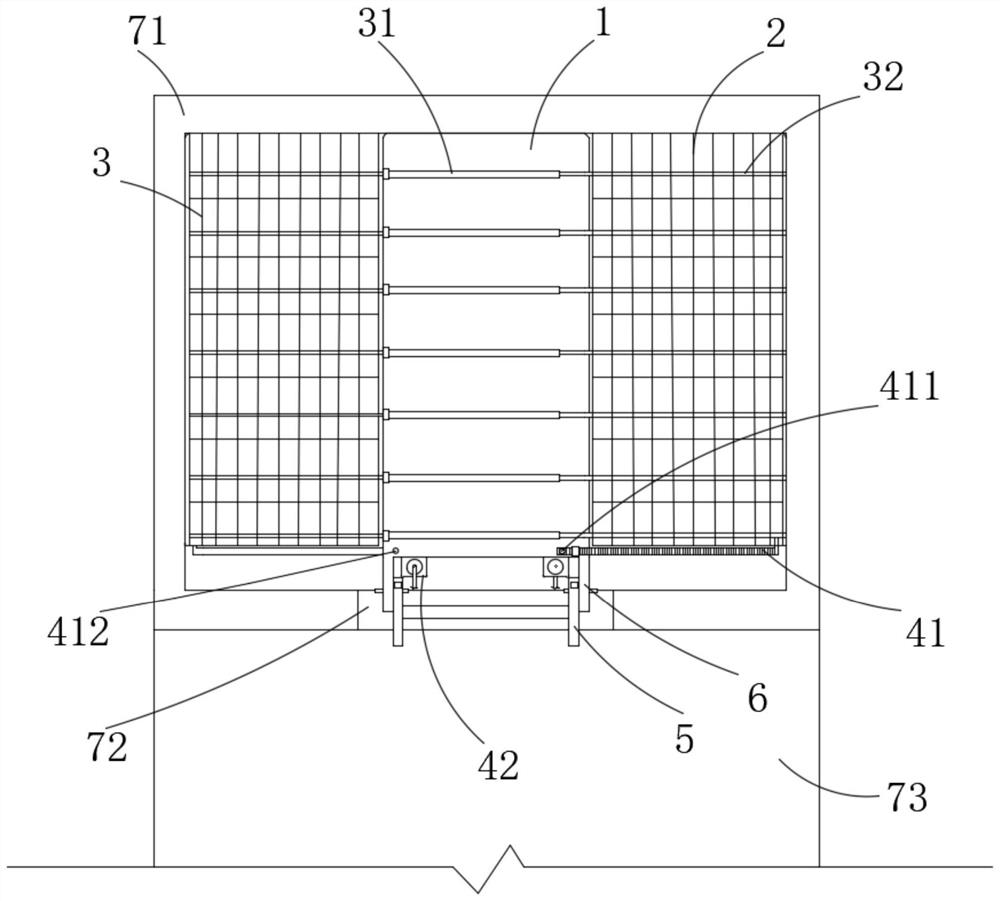

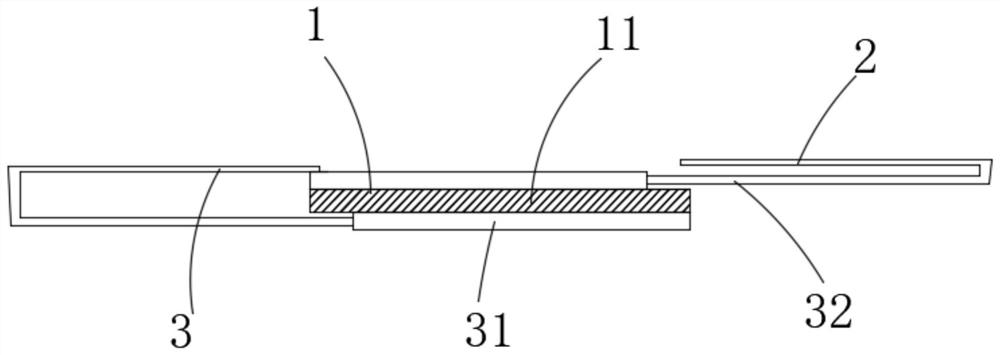

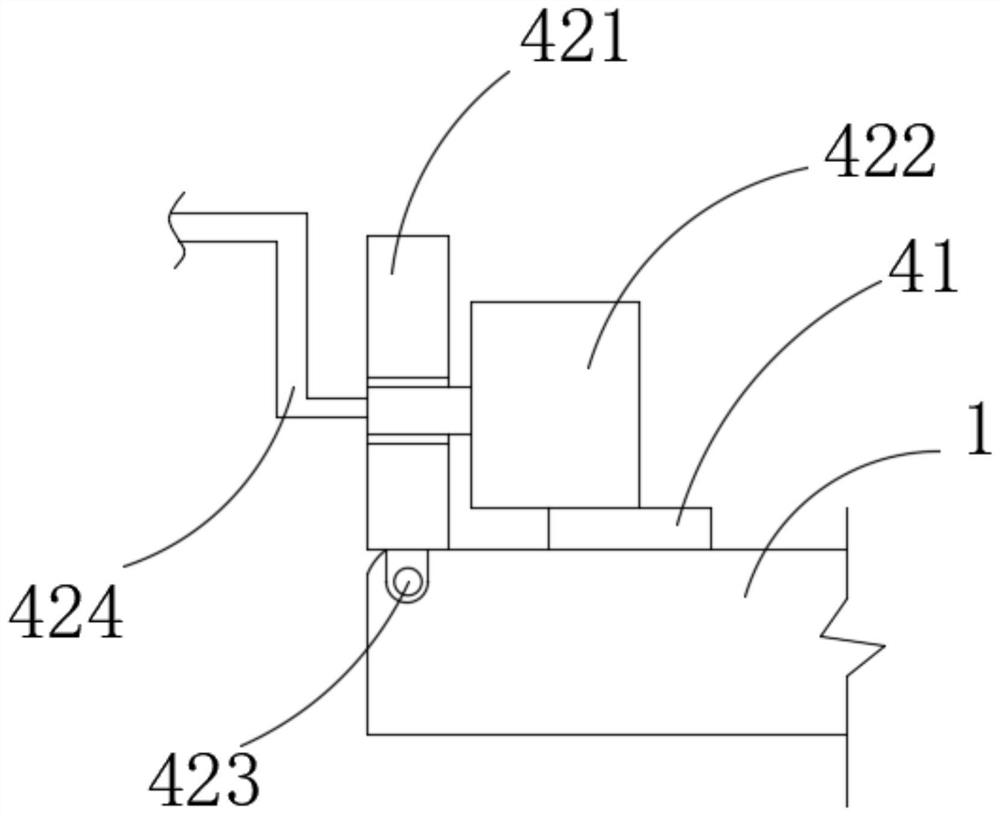

[0022] Such as Figure 1~4 As shown, the present embodiment provides a technical solution: a telescopic safety baffle structure for an elevator shaft, including a main board 1, a first sub-screen board 2, a second sub-screen board 3, a telescopic assembly, and a recovery assembly. Both the first secondary net plate 2 and the second secondary net plate 3 are connected to the main board 1 through the telescopic assembly, and the recovery component includes a follower rack 42 and a foldable recovery gear member 42. The follower rack 42 is arranged on the telescopic assembly, can move with the telescopic assembly and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com