Bar circular vibrating screen device

A circular vibrating sieve and rod technology, which is applied in the direction of filtration, solid separation, grille, etc., can solve the problems of single material size, inability to screen, and unsatisfactory screening effect of non-vibrating rod sieves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

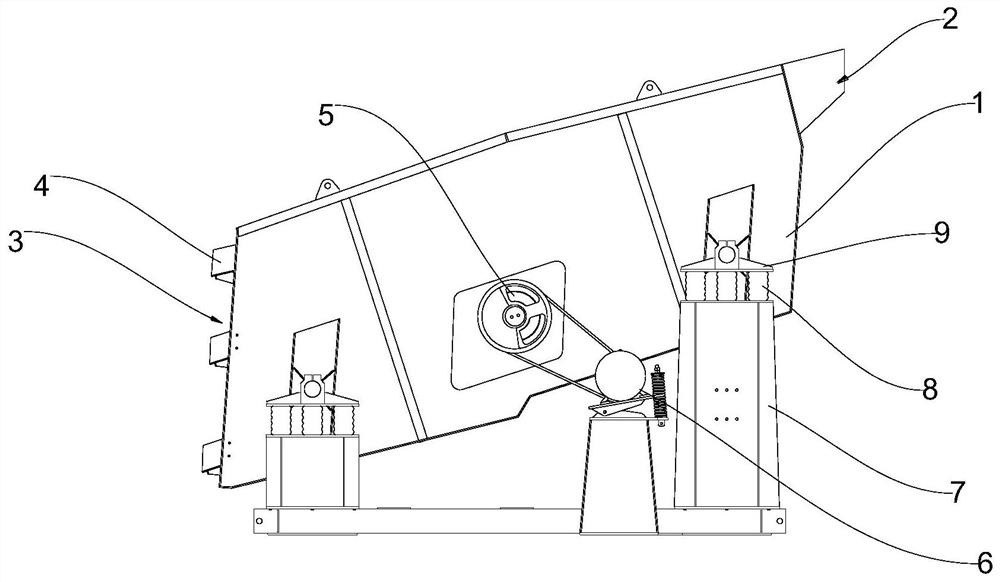

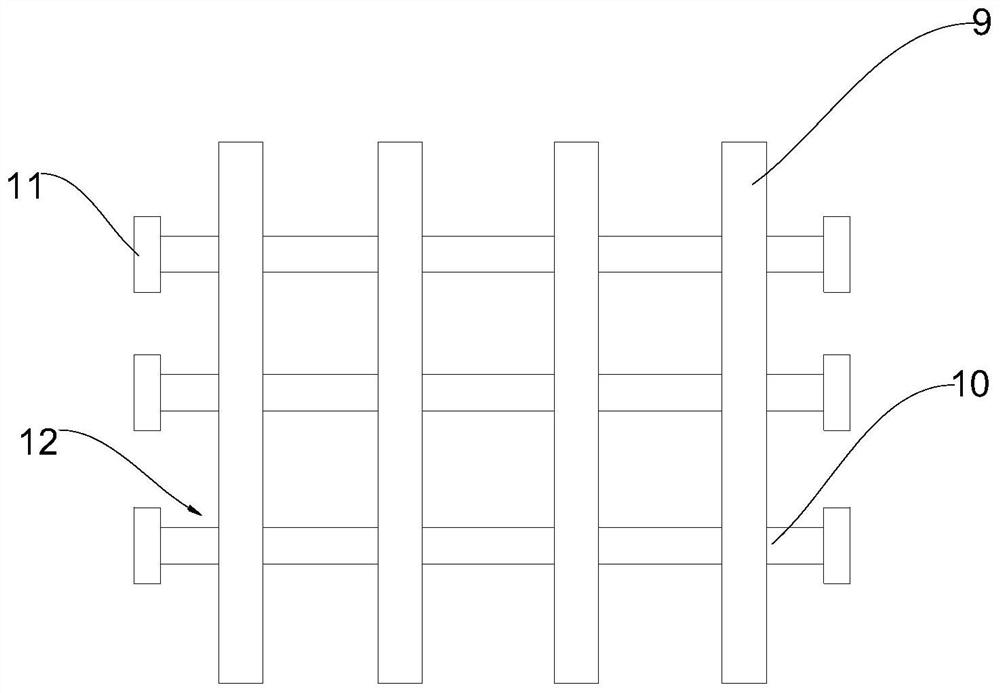

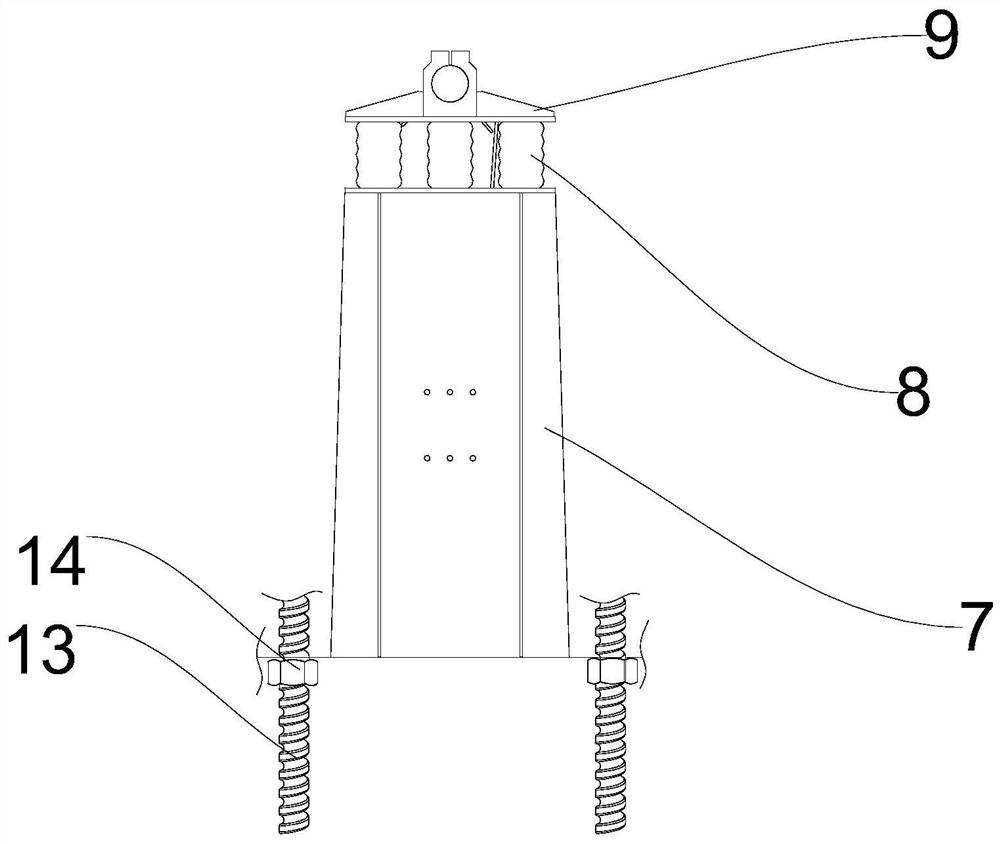

[0033] Please refer to Figure 1-Figure 3 shown. This embodiment provides a bar circular vibrating screen device, including a screen box 1, the screen box 1 includes a feed port 2 and a discharge port 3, the bottom of the screen box 1 is connected with a support seat 7, and the screen box 1 is connected with a vibration assembly A plurality of screens 4 are installed in the screen box 1, and the plurality of screens 4 are located at different levels, and any one of the screens 4 is detachably connected to the screen box 1.

[0034] In the above embodiment, the screen box 1 includes a feed port 2 and a discharge port 3, and the screen box 1 is provided with a multi-layer screen 4 for screening materials, wherein the screen 4 is detachably connected to the inside of the screen box 1. The screens 4 are located at different levels. Assuming that the screen box 1 contains the first layer of screen 4, the second layer of screen 4 and the third layer of screen 4, the first layer of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com