Preparation method of ZrO2-Al2O3 composite ceramics

A technology of composite ceramics and alumina, applied in the field of preparation of metal oxide materials, can solve the problems of complex equipment process, high energy consumption, serious pollution, etc., and achieve the effect of excellent performance and good microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

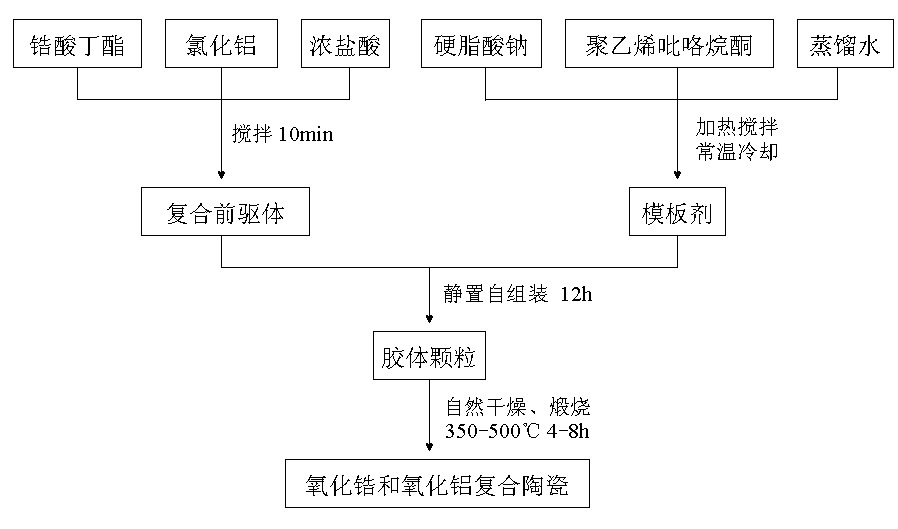

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: prepare composite ceramics according to the following steps

[0019] Step 1: Dissolve 1.3g of butyl zirconate and 0.13g of aluminum chloride in 1.0g of concentrated hydrochloric acid with a mass concentration of 37%, and magnetically stir for 10 minutes to obtain a clear precursor solution, which is spread in a container;

[0020] Step 2: Dissolve 0.25 g of the surfactant sodium stearate and 0.25 g of polyvinylpyrrolidone (PVP) in 18.4 ml of deionized H 2 In O, stir magnetically at 40°C for 15 minutes to obtain a uniformly mixed template solution;

[0021] Step 3: Cool the templating agent solution in step 2 to room temperature 25°C, pour it evenly into the container in step 1, transfer the container to an artificial intelligence climate box with a constant temperature of 21°C, and let it stand for self-assembly for 12 hours to obtain the Zr-Al base colloidal particles;

[0022] Step 4: Dry the colloidal particles in step 3 naturally, and heat-treat at 3...

Embodiment 2

[0023] Embodiment 2: prepare composite ceramics according to the following steps

[0024] Step 1: with step 1 of embodiment 1;

[0025] Step 2: Dissolve 0.25 g of surfactant sodium lauryl sulfonate and 0.25 g of protein in 18.4 ml of deionized H 2 O in 40°C magnetically stirred for 15 minutes to obtain a uniformly mixed template solution;

[0026] Step 3: same as step 3 of Example 1;

[0027] Step 4: Dry the colloidal particles in step 3 naturally, and heat-treat at 400°C for 6 hours to obtain ZrO with mesoporous ordered structure 2 -Al 2 o 3 Composite ceramics.

Embodiment 3

[0028] Embodiment 3: Prepare composite ceramics according to the following steps

[0029] Step 1: with step 1 of embodiment 1;

[0030] Step 2: Dissolve 0.25 g of surfactant dodecylbenzenesulfonic acid and 0.125 g in 16.4 ml of deionized H 2 In O, stir magnetically at 40°C for 15 minutes to obtain a uniformly mixed template solution;

[0031] Step 3 is the same as step 3 in Example 1;

[0032] Step 4: Dry the colloidal particles in step 3 naturally, and heat-treat at 450°C for 5 hours to obtain ZrO with mesoporous ordered structure 2 -Al 2 o 3 Composite ceramics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com