Curved glass or glass ceramic moulded part and method for producing same

A glass-ceramic and glass-forming technology, which is applied in the field of manufacturing curved glass moldings or glass-ceramic moldings, and can solve problems such as interruption of glass layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

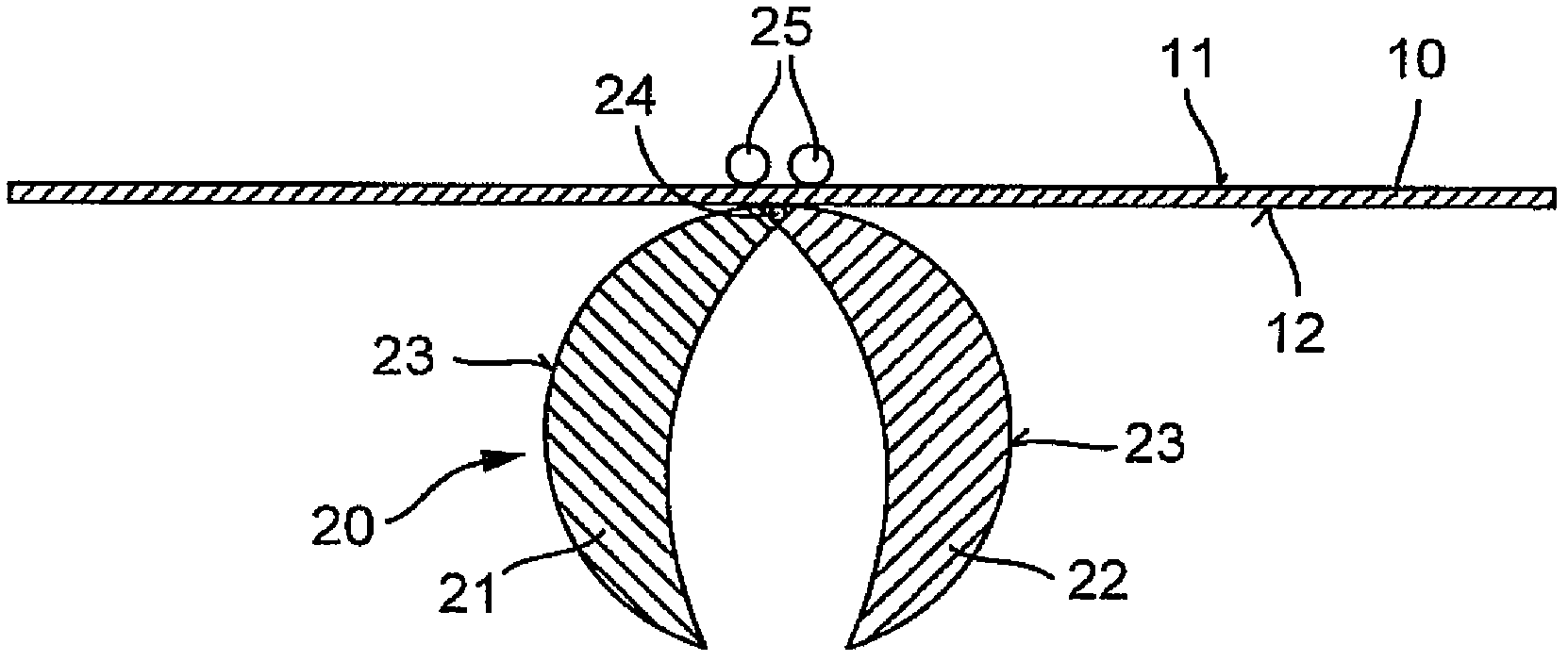

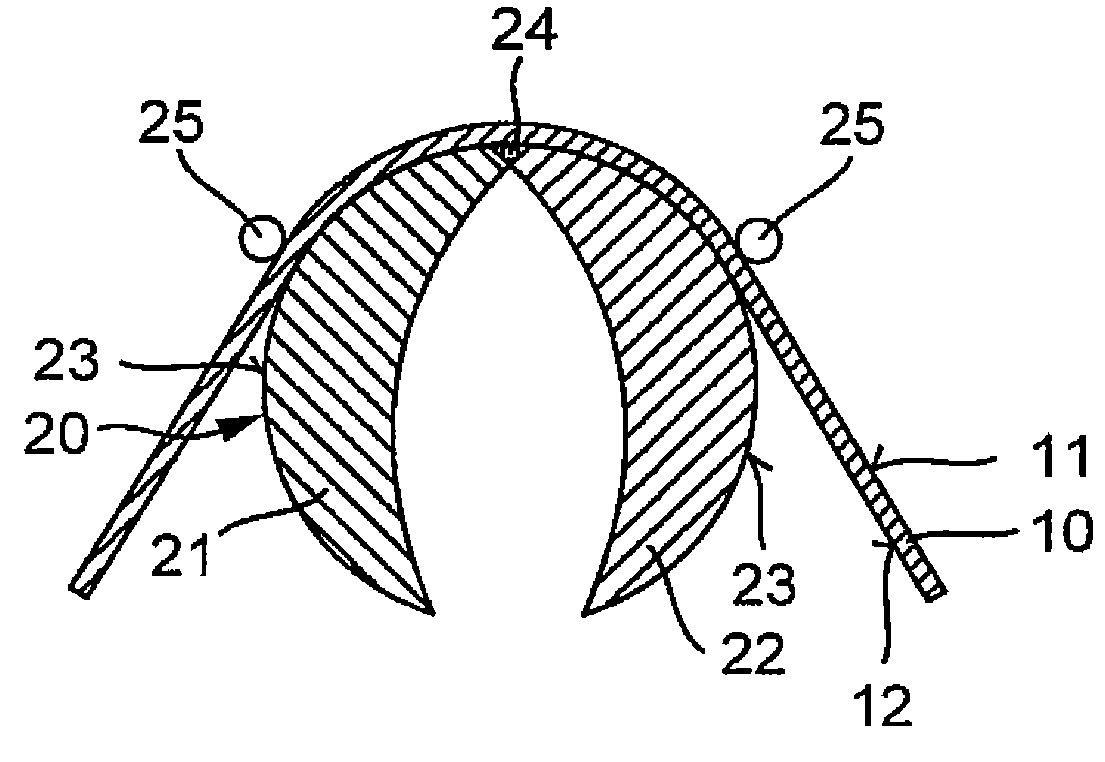

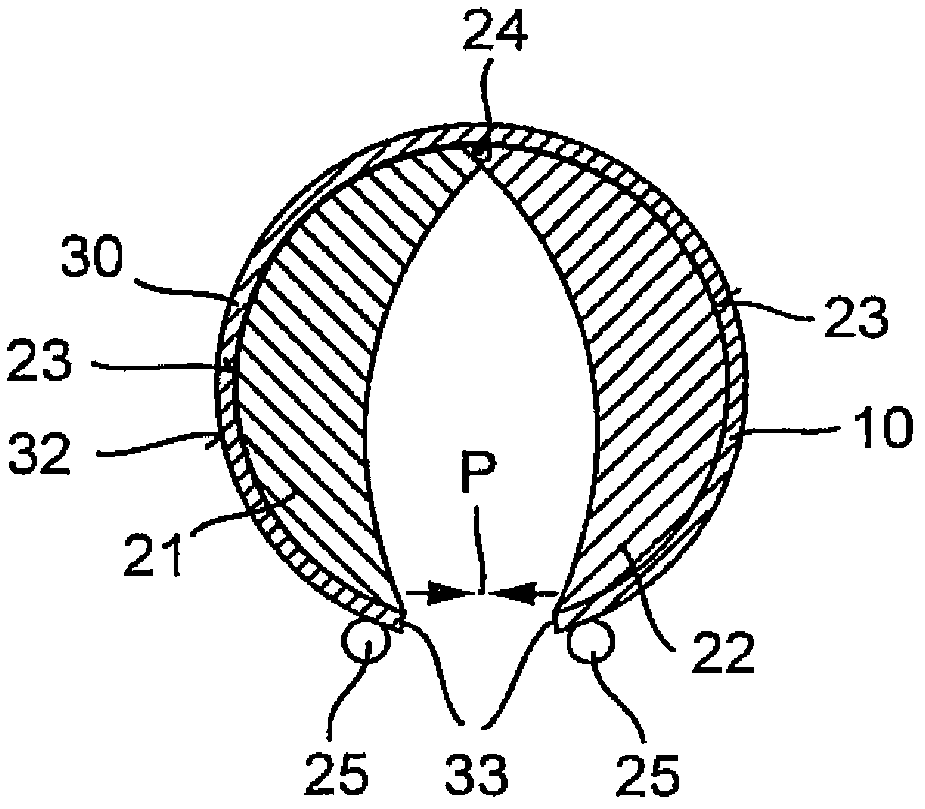

[0027] figure 1 A mold 20 is shown, which has two molded parts 21 and 22 that can move toward each other. Here, the two supporting bodies 21 and 22 are coupled around a movable connecting piece 24. Preferably, the movable connecting piece is formed by a hinge having a pivot axis. The two supporting bodies 21 and 22 respectively have an arc-shaped supporting surface 23, wherein the two supporting surfaces 23 realize a common partial cylindrical plane. In the area of the movable connecting element 24, a rectangular or square green glass cutting section 10 is arranged. Green glass cutting sections 10 of other contour shapes are also conceivable. The blank glass cut section 10 is placed above the support bodies 21 and 22 with its bottom side 12. Two pressing devices 25 act on the upper side 11 of the blank glass cutting section 10. The two pressing devices 25 hold the cut section of green glass on the supporting surface 23. In the next method step, the green glass cutting s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com